Reasons for insufficient sound insulation

By law, developers are required to comply with noise protection standards for residential buildings. However, builders soundproof buildings at a minimum level, just to get a positive expert opinion. As a result, residents of houses built even after 2010, when this standard was made mandatory, independently arrange soundproofing for their apartments. What can we say about houses built earlier?

Meanwhile, the owners of “noisy” apartments do not know how to properly soundproof their home and spend money uselessly, buying insulators that are not what they need and installing them in a way that is not required by the technology.

The reasons for poor sound insulation lie in the materials from which the floors and walls are made, in open joints between blocks in partitions, voids and cracks in structures. Before laying protective coverings, find out how extraneous sounds enter the room. Because the method of protection depends on these factors.

MaxForte Standard

The Russian company MaxForte, together with the country's leading universities, has developed a material that can completely soundproof an apartment. In addition to sound, it also keeps out the cold. It can be used for thermal insulation. Standard is very easy to use. Its thickness is 12 mm. The thin and elastic structure does not ignite. The material also has good contact with cement or gypsum.

The advantages of this material:

- Ecological coating does not cause any harm to human health;

- The material is easy to install, as its thickness is 12 mm;

- Low cost (800 rub/m2).

The disadvantage of using MaxForte standard is that if installed incorrectly, sound from neighbors can enter the apartment. Therefore, it is recommended to order the services of specialists.

Types of noise

There are three types of noise that propagate in rooms:

- air;

- shock;

- structural.

Airborne noise is called that way because it travels through the air. Sources: cars, televisions, musical instruments, loud speech.

Impact noise is generated by floors, walls, and pipes when a heavy object falls on them or a child hits them with anything.

Structural noise is produced by pumps, elevators, and fans. Vibrations from mechanisms are transmitted through building structures.

If through the wall you can hear your neighbor “nag” her husband, protect yourself from airborne noise. If the clatter of heels from the ceiling irritates you, it’s from the impact. If the dishes clink when the booster pump is turned on, eliminate structural noise. Well, if they got both together, they do comprehensive soundproofing of the apartment.

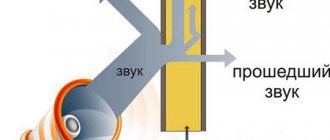

Absorbers and reflectors

Materials that resist the spread of noise are divided into reflective and absorbent. The first reflect sound vibrations, preventing them from spreading further, for example, passing through a wall. The latter absorb them, preventing them from being reflected from the obstacle and returning back.

Reflectors include hard materials: concrete, brick, wood, metal. Soft coverings absorb sounds: carpet, mineral wool, rubber, cork.

To protect premises from outside noise, reflective materials are used, and the outside world is isolated from indoor noise by absorbers.

In reality, both types of materials have reflective and absorptive properties, but to different degrees. The denser the absorber, the better it reflects sound. Therefore, pressed mineral wool, for example, is used to protect against both external and internal noise.

Popular sound insulators

In brick houses, noise penetrates into apartments through concrete floors. They insulate floors and ceilings. In panel and monolithic buildings, sound vibrations are also transmitted through the walls, so they are also sheathed.

Airborne noise is reduced using mineral wool, fiberglass and multilayer coatings made on their basis.

Mineral wool has sound-absorbing and heat-insulating properties. It does not form fungus and mold, it is fireproof. Glass wool is elastic and light. It also works as insulation.

Taking into account the fact that these materials are produced in different versions, acoustic options are used for sound insulation, the manufacturing technology of which differs from the production technology of heat-insulating boards. The purpose is indicated in the passport or instructions. The sales consultant will also provide recommendations for selection.

AcousticWool Concept, acoustic mineral wool, 54 kg/m3 - 255 RUR/m2, online store Stroymateriall.ru.

Fiberglass plate Shumanet EKO SK 1250x600x50 mm - 825 rub./pack of 4 pcs., construction hypermarket Isolux.ru

Multilayer panels are used simultaneously as a sound and heat insulator. These are ready-made structures; their use reduces installation time.

Soundproofing panels EcoZvukoIzol Mini, 1200×450×13 mm — 450 rub.

Materials made of cork, rubber, polyethylene and other absorbing materials protect against impact noise. But they do not work well against street noise, since they almost do not reflect sound.

Pressed sheets of cork and rubber do not rot, do not change properties when temperature changes, and are durable. Used under textile floor coverings, linoleum, parquet, tiles.

Rolled cork backing Cork, 10x1 m, thickness 4 mm - RUB 2,730/roll

ABEX-P based on rubber for sound insulation - 100x10000x5 mm - 2900 rubles, TUTTIKHO online store

Extruded polystyrene foam (polyurethane) was originally used as insulation, but tests have shown that it absorbs impact noise. A 20 mm thick layer reduces sound by 23 dB (every 10 dB reduction reduces sound intensity by 2 times). It is compression-resistant, moisture-resistant, easy to install, and has been in use for more than 50 years. The minimum layer thickness for floor soundproofing is 40 mm.

Soundproofing panels with polystyrene are better at blocking noise.

Foam sheet XPS TECHNOPLEX 1.2x0.6 m 20 mm - 205 rubles, OBI

Panel based on extruded polystyrene foam Ruspanel RP 10 XPS 2500x600x10 mm - 670 rubles, GDEMATERIAL store. It consists of a soundproofing layer of MDVP, a thermal and waterproofing layer of XPS (extruded polystyrene foam) and a reinforced layer of fiberglass mesh and a polymer-cement composition. A finishing coating is applied to the slab.

To eliminate structural noise, fill voids in mounting boxes and socket openings with acoustic mineral wool or gypsum mortar.

Construction plaster G5 BII, 35 kg - 205 rub., Geostyle online store

Risers that were not placed in larger diameter insulating pipes filled with sound-absorbing material during the construction of the house are wrapped in asbestos fabric and coated with glue-sealant. If such a sleeve is present, seal the space between it and the riser with silicone sealant.

Asbestos fabric AT-2 GOST 6102-94 - 378 rub./m2, online store "Tradecons"

Sealant Accent 105 silicone, 0.3 kg - 113.5 rub.,

The gaps between the walls and the floor are insulated as follows. A 30-50 mm wide seam is cut into the screed along the walls to the depth of the screed. Fill with cement-sand mixture. When the cement has dried, it is treated with a non-hardening sealant.

Non-hardening sealant Stopaq FN 2100, set - 1944 rubles, Stroymost store

If it is impossible to reach the screed, fill the gap between the wall and the top covering with silicone sealant.

The connections between the walls and the ceiling are cleaned and sealed with putty or cement mortar. Dried surfaces are treated with glue-sealant.

EcoAcoustic Maxforte

The main material of this soundproofing element is polyester. The composition has been modernized by leading Russian universities. After development, EcoAcoustic acquired light weight and good sound insulation. It's easy to cover an apartment yourself.

Pros of EcoAcoustic Maxforte:

- The frame is not flammable;

- Does not absorb liquid;

- Does not react with chemical solvents;

- Does not come into contact with mold and fungi;

- Keeps the apartment warm well.

The material is sold in sheets that can be easily cut with a knife to soundproof small areas of the wall.

Comprehensive noise protection

Soundproofing the floor

If various noises “walk” around the apartment, comprehensive sound insulation is done, protecting the floor, walls and ceiling. Other options lead to unnecessary expenses, and the rooms do not become quieter.

When making complete sound insulation, take into account that the result will only be achieved if the materials are chosen correctly and the technologies recommended by the manufacturer are used. For example, an expensive structure for soundproofing a ceiling is useless if 10-15 holes are drilled in it for recessed lamps.

A noisy floor is a covering laid on a base without a noise-reducing underlay. It transmits sounds in all directions: from the floor below, to the apartments on the right and left, and also reflects back into the room. That is, it causes inconvenience to both owners and neighbors.

The solution to the problem is a screed separated from the walls and ceiling. Due to the fact that it is not rigidly fastened to the walls and base, it is called floating. Install such a screed in the following order.

A polyethylene film is stretched over the base - it will prevent leakage when pouring the floor. Sheets of dense mineral wool grade P-125 50 mm thick or a rolled sound insulator of the Schumanet type are laid on polyethylene. They dampen shock vibrations and insulate the floor. They are laid so that they extend onto the walls to the height of the screed, separating it from the structural elements of the house. The same materials, cut into strips 10-20 mm wide, are used to separate communication pipes from the screed.

Mineral wool board P-125, 1000x500x50 mm - 2047 rub./m3

Shumanet Eco sound insulation, 3 m2, 4 pcs - 816 RUR, online store StroyOutlet.ry

The floor is filled with a 50 mm thick screed, reinforcing it with a metal mesh with 100x100 mm cells for strength. We recommend using a semi-dry screed: it is laid by machine and dries within a day.

Soundproofing walls

The walls are covered with sheets of high-density mineral wool 50 mm thick and sheathed with plasterboard on the frame. A damper tape is placed under the guide profiles. The mineral wool is laid so that the top edge reaches the ceiling by 200-250 mm.

To prevent the walls from looking crooked, the frame is mounted strictly in one plane. It is not attached to the ceiling, leaving the top of the supporting profiles without guides. This separates the cladding from the structural elements of the house through which vibrations are transmitted. The strength of this design is ensured by the guides of the ceiling frame, which tighten the load-bearing profiles of the walls, forming a single structure. Drywall is painted, covered with wallpaper, and covered with tiles.

Knauf plasterboard sheet 3000x1200x12.5 mm - 305 rubles, construction hypermarket Isolux.ru

Damper tape, 20 m - 200 rub., Polisintez online store

Guide profile PN 28x27x0.6mm, 3m Knauf - 90 rub., Famarket online store

Rack profile PS-2 50x50 mm, 4 m Knauf - 287.35 rubles, construction hypermarket Isolux.ru

Ceiling soundproofing

The ceiling is sheathed in the same way as the walls. The frame is mounted and the free space between the profiles is filled, but the sheets are not compacted.

Let us remind you that built-in lamps are not installed. The holes impair sound protection, and lamps mounted in a space deprived of ventilation burn out from overheating after 5-7 hours of continuous operation. On such a ceiling, overhead lamps are hung or wall sconces are installed.

Soundproofing walls in an apartment on your own: technology

Let's consider the sequence of work on installing plasterboard cladding on a metal frame filled with basalt wool lamellas.

Soundproofing the walls in an apartment with your own hands will require preparing the surface of the walls and purchasing materials. Required:

- Metal profile for frame;

- Soundproofing gasket under the profile;

- Soundproofing slats;

- Drywall.

A metal frame is built along the prepared wall with a pitch of 600 mm and longitudinal struts every 1200 mm. The frame is attached to the wall through a soundproofing gasket. Experts recommend laying gaskets in two layers. Lamels are inserted into the cells of the frame. The frame cells must exactly match the size of the soundproofing boards. Drywall is attached to the frame with self-tapping screws. The final finishing is carried out - sealing the joints with serpentine putty, filling the surface, priming, painting or wallpapering. The walls in the apartment were soundproofed with our own hands.

ZIPS panels

To speed up installation, ready-made soundproofing structures are used. One of these is ZIPS panels.

Soundproofing panel system (ZIPS) is a multi-layer frameless covering. They are sandwich panels with a thickness of 4 to 12 cm with a front layer of acoustic plasterboard sheets. The panels are fastened to ready-made vibration-isolating units by screwing dowels into them.

They produce panels of different thicknesses for walls, floors and ceilings. The following types of coatings are used in residential premises.

ZIPS-floor

Sandwich panel with vibration supports, acoustic layer and front plywood board. Absorbs the energy of airborne and impact noise. Installation requires a level subfloor.

ZIPS-Floor Module, sandwich panel, 1200x600 mm - RUB 1,497.60/piece, construction hypermarket Isolux.ru

ZIPS-Ultra

Consists of a sandwich panel and acoustic plasterboard. The sandwich panel includes a layer of gypsum fiber and a layer of Shumostop material. Used for soundproofing single-layer partitions made of concrete, brick, plaster, walls and ceilings made of reinforced concrete.

ZIPS-III-Ultra with fastening kit, 1200x600 mm - 1480 RUR/piece, online store NoiseStop.ru

ZIPS-Vector

The thin version of the system is no more than 5.3 cm thick. Includes a gypsum fiber sandwich panel and “Noisestop”. Used to reduce the level of airborne noise of low power (calm conversation, working TV)

ZIPS-Vector system, 1200x600x40 (0.72 m2/piece) with fastening kit - 1176 RUR/piece, BEZ-SHUMA online store

ZIPS are mounted through vibration-isolating units, which, according to the manufacturer, reduces the noise intensity to the maximum. Vibrations are also reduced by the absence of a frame - they weaken as they successively pass through the layers of the sandwich panel. The tongue-and-groove joining of the panels, which makes the prefabricated structure a monolith, also improves soundproofing.

Among the advantages, consumers note the simplicity and speed of installation of ZIPS panels, since they leave the factory ready for use. But they also point out serious, from their point of view, shortcomings. First of all, I don’t like the price, which one of the forum members called prohibitive.

In addition, it is allegedly difficult to hang a shelf or cabinet on the panel, since the fasteners do not hold well in the body of the panel. You won’t be able to install electrical wiring if you suddenly need to connect new devices.

If the last two opinions belong to people who do not consider planning an important component of preparation for renovation, then most apartment owners would not call the statement about the high price subjective.

Calculations show that the option of soundproofing with mineral wool under sheets of plasterboard will cost less, and the results will not be inferior to ZIPS. But installing it is more difficult and takes longer.

SoftBoard

The main composition of this sound absorber includes wood fibers. During production, the wood is finely ground to form a powder. Then the resulting mixture is placed under a press.

Advantages of using SoftBoard soundproofing:

- The durable composition of soundproofing material is used for finishing not only walls, but also ceilings and floors;

- The material does not allow water vapor to pass through, so it can be installed in the bathroom or kitchen.

- It is moisture resistant, which means it is not capable of breeding bacteria.

- SoftBoard is easy to visualize externally. The material can be painted or wallpapered.

Disadvantages of using the material:

- Thick panel layer 30 mm;

- Withstands a shock wave of up to 20 dB, which is small compared to competitors.