Composition and types

Manufacturers produce a number of modifications of eccentric couplers, the constituent elements of which are:

- stand (rod);

- futorka (performs the function of a nut);

- eccentric;

- metal or plastic sleeve, dowel;

- plug for minifix - at the discretion of the manufacturer.

The assembly of massive furniture elements involves the use of a reinforced eccentric, which is encased in a body and has an additional foot. In this case, the tie can be tightened by placing the screwdriver at an angle.

Hardware manufacturers also offer furniture assemblers corner (with hinge) and double-sided eccentrics. Only recently they have not been in demand.

All components of the eccentric are divided according to the following parameters:

- kind of futorka;

- size and diameter;

- type of stand - short (up to 3.8 cm), long (up to 5.8 cm), double-sided;

- type of rack attachment - self-tapping screw or self-tapping screw.

Similar minifixes are used for assembling products from chipboard or chipboard. It is advisable to use such ties in secluded places where fastening marks will be practically invisible. You can only see the eccentric, and even then only from the inside. Subsequently, to give the furniture an aesthetic appearance, it is hidden with a plug.

Assembly sequence

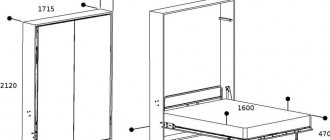

To install eccentrics, you must have a certain tool:

- a set of drills with a diameter of 7.0 mm (for the rod body), 53.0 mm (for tightening the stand);

- screwdriver;

- Forstner router with a diameter of 15.0 mm;

- screwdriver, pencil, awl and square (ruler).

The assembly sequence is as follows:

- a restex stand is screwed into the plane of the panel body, to which another part will then be connected at the end side;

- An eccentric is mounted at the end of the second shelf, tightening the rod by turning it towards itself.

To maintain utmost punctuality in fitting the required holes, a template is often used.

Pros and cons of fasteners

The minifix fastening connection evokes only positive emotions among craftsmen, since it has obvious advantages over other types of fasteners.

Furniture assemblers attach particular importance to such advantages of eccentrics, because they:

- Easily cope with impressive loads. Eccentric fasteners are very reliable and can withstand a large number of assemblies/disassemblies of wooden structures without loss of strength and quality of the connection.

- A very durable and economical fastener.

- Increases the rigidity of the manufactured product.

- Eccentrics refer to fast or quick installation screeds. Assembly of all kinds of furniture with built-in minifixes is minimal in time and all you need is a classic slotted screwdriver.

- The elementary nature of the assembly work allows any average person to carry out the installation with their own hands.

- It does not spoil the aesthetic appearance of the product at all - it is not noticeable after installation and does not leave visible defects or damage.

There are no significant disadvantages to such clamps, but still some disadvantages can be traced:

- The cost of the eccentric is slightly higher than that of typical confirmats. If the assembly of a piece of furniture involves a significant amount of such fasteners, then the final cost of the product will increase significantly.

- The installation technology is not entirely simple; you need to make three holes for fastening and have special, precise equipment available.

- High demands on marking accuracy, without which it is unlikely to be able to ensure the strength of the joints of furniture units.

- During the operational period, the screed may weaken slightly.

To obtain a durable, high-quality and durable piece of furniture, it is worth adopting just such a fastening element.

Video lessons and photographic materials that can be found on the Internet will help self-taught amateurs to assemble cabinet furniture technically correctly. You can also study the instructions that come with the product.

Watch the video in which a specialist talks about eccentric screeds in furniture production:

Source: anatomia-remonta.ru

Types of furniture components, their purpose and installation methods

Today, designers are given complete freedom of action. Furniture manufacturers have stepped far forward, so now we enjoy a variety of models and choose our favorite furniture components. But design cannot be complete without furniture fittings, which affect the technical characteristics and functionality of products.

Accessories

Furniture fittings are all kinds of fasteners, handles, curtains, supports and decorative elements. They are made of metal, wood, plastic and other materials. Metal products are treated with special anti-corrosion agents to extend their service life. For luxury-class designs, the fittings can be gold-plated or silver-plated, as well as trimmed with rhinestones, crystal or natural stones. Conventionally, fittings can be classified by type.

Connecting fittings – connects and fixes parts together. This group includes one-piece, detachable and movable elements:

- Permanent connections include screws, ties, screws, nails, bolts, brackets, hooks, upholstery buttons of upholstered furniture. The tie can be eccentric or connecting. Galvanized steel is used for the eccentric tie and makes it durable. The corner tie does not require additional holes in the ends of the furniture. Threaded ties include a nut and a screw that create a strong connection. A wedge coupler is also used for quick connection. It is based on plates, wedges and staples. The ties are connected with traditional screws;

- Detachable connections? These are door handles, latches, shelf holders, magnetic devices, locks, deadbolts. To fasten detachable structures, screws and self-tapping screws are used;

- Mobile? these are hinges, “rails” for parallel movement of the door, microlifts. Pneumatic mechanisms and ball-bearing guides take on the entire load.

For furniture made from chipboards, it is not recommended to use piano hinges, which were used several decades ago. Today, manufacturers use four-joint designs called "frog". They can withstand a 10,000th door opening/closing cycle.

Detachable

Movable

One-piece

Rotating elements? These include carousel mechanisms, structures for moving tabletops apart, and for directing the movement of products. For example, the shelf rotates along its axis and makes it easy to get the desired item. Basically, furniture structures are built using guide systems, which are used to pull out elements. They can extend fully or partially. Thanks to special rollers, such systems operate smoothly and almost silently. They are made of steel, fluoroplastic or duralumin. If we consider the importance of fittings as a percentage of the cost of cabinet, upholstered and kitchen furniture, we get the following results: in cabinet furniture, fittings account for 10-15% of the total cost of the product. For a kitchen, the importance of fittings is 25% of the cost of the set, and for upholstered furniture it is 30-40% of the cost of the product.

Rotary

Accessories for assembly? When purchasing furniture, you need to pay attention to the fittings and upholstery fabric, determine their quality and strength. And also on the assembly details of the product, which include furniture corners, confirmants, rafixes, minifixes and dowels:

- Furniture corners? simple, cheap and accessible types of connections. On the construction market they are presented in different sizes, made of plastic and metal. Corners are designed for fastening hinged parts in pencil cases and cabinets. They are easy to install, have a low price, but are noticeable, which slightly spoils the design of the structure;

- Confirmation? furniture euroscrew, which received its name from the German manufacturer. A furniture screw tie, consisting of a steel rod with a blunt ring, a head and a massive thread, is capable of connecting several wooden elements at once. The confirmation is visible in the design, so it is masked with a plug. The most common are screws with dimensions of 7x50 mm or 6.3x50 mm;

- Dowel? a connecting element that is used for assembling wooden, plywood and chipboard furniture parts. It is made of hardwood and has a cylindrical shape with chamfers. Today plastic dowels are also produced. They strengthen furniture connections with confirmat, minifix and rafix. Used with PVA glue as an independent fastening element;

- Minifix? is an eccentric coupler for furniture joints, consisting of two parts? rod and eccentric. Minifix has a different design, which makes it possible to increase the length of the element and connect it at different angles. For installation, use a 15 mm cutter and drills, with which three holes are drilled. The fastening turns out to be complex and requires precise calculation;

- Rafix? used in visible places to connect furniture parts of tabletops, side parts of furniture structures. It is installed on two holes, has an eccentric mechanism and a rod. Rafix has a beautiful aesthetic appearance, but it is not particularly durable.

Dowel

Rafix

Minifix

Furniture corners

MinifixFacades

In a furniture design, all visible parts that face the front or side plane are called facades. Their configuration and color determine the style of the furniture and set the tone for the entire room.

Main types of facades:

- Doors;

- Front walls of drawers;

- Horizontal and vertical decorative overlays;

- Furniture cornices.

The facade can be easily unfastened from the attachment fastening, replaced with a new one and adjusted in vertical, horizontal and inclined positions. Do different circumstances lead to the replacement of façade elements? careless use, mechanical damage, outdated design, discoloration of the structure due to exposure to ultraviolet radiation. To make furniture with your own hands, use solid ? “blind” and prefabricated frame-paneled facade elements.

Most often used for the production of facades:

- Chipboard;

- MDF board;

- Natural wood (solid);

- Furniture board;

- Metal (stainless steel, aluminum);

- Glass.

Budget furniture is made from laminated chipboard. MDF boards make beautiful structures finished with film, paneling or veneer.

Premium products include elements made from natural wood. Today the market offers modern facades made of aluminum profiles. It looks organically with glass, plastic, rattan and other materials. To fill the profiles, genuine leather, textile fibers, and polymer 3D photo printing are used.

Chipboard

Glass

MDF

Furniture board

Natural wood

MetalFacade dimensions

The construction industry has introduced a wide range of façades with different dimensions to the market. The size of the frame facade depends on the profile, and the dimensions of products made from MDF boards depend on the capabilities of industrial equipment. For example, the minimum height of solid facades is ? 137-140 mm, minimum width? 296 mm, and maximum height? 988-1250 mm and maximum width? 596-1200 mm. And in frame-panelled facades, the minimum height is 562-573 mm, the minimum width is ? 296 mm, and the maximum width is 596-896 mm and the maximum height is ? 980-1010 mm. When choosing a facade product, you need to pay attention to the beautiful design, the ability to fit into the interior of the room and the performance characteristics of the materials.

Mechanisms

Designers and design engineers of furniture production are working on new and improving existing mechanisms for the kitchen, cabinet sets and upholstered products. Thanks to lifting systems, opening of façade elements occurs quietly and easily. They can be fixed at any height and in any position. Let's look at the main types of lifts.

- Folding? they are used for multi-tiered wall cabinets and double-leaf facades;

- Folding? mechanisms are installed on large blind facades of the upper tier, if the structure contains overhanging artificial lighting and canopies;

- Vertical? lift façade elements upward on any tiers of the suspended structure;

- Rotary mechanisms? capable of turning and stopping a solid facade when opening in any position;

- Mechanical? they help open the doors in the upper and lower positions;

- Gas elevators or gas lifts ensure smooth opening and closing of façade parts. Automatic gas lifts are not able to fix the opening of doors in a certain position. Gas lifts, the design of which includes step-by-step or frictional openings, have the ability to fix the door at any height. This mechanism is convenient for residents with short stature and high cabinets.

Folding

Rotary

Mechanical

Folding

Gas

Vertical

Types of retractable mechanisms:

- Roller guides are among the simplest and most cost-effective mechanisms. Steel runners slide in them using plastic or rubber-coated rollers. Their design reduces noise when furniture drawers are pulled out;

- Metaboxes are a roller system with two symmetrical metal sides that move along roller guides. They extend the product partially (3/4) or completely by 270-550 mm and withstand a maximum dynamic load of up to 25 kg;

- Ball-type? telescopic guides, which professional furniture makers use in their work. The system allows the drawer to open completely and smoothly, it is durable, silent and wear-resistant;

- Tandemboxes? a retractable system that allows the drawer to open with a light hand press on the front.

The choice of a cabinet, chest of drawers, hallway, kitchen depends on the retractable system, since the drawers present in the design are in constant use. When buying upholstered furniture, special attention should be paid to the sofa and its transformation mechanism.

Types of sofa transformation mechanisms:

- Folding;

- Retractable;

- Unfolding.

Main types of construction:

- Eurobook? The mechanism is durable and has a long service life. Wide seats are not comfortable for short people;

- Book? A simple and durable design that easily converts a sofa into a sleeping area. It cannot be placed close to the wall, as it requires significant space to unfold;

- French folding bed? The system is of the guest type. To unfold it, you need to pull the bottom of the sofa and 3 soft elements will extend into the sleeping area. The mechanism is not adapted to frequent transformation. It suits small spaces;

- Roll-out sofa? the mechanism consists of two segments, which are located in the structure of the sofa. When the front lower part is extended, the vacated space is taken by the back cushion. The design is compact in size and allows you to get a comfortable place to sleep. But you need to make sure that the rollers do not scratch the floor;

- Accordion? a transformation mechanism that makes the place to sleep high and comfortable. When folded, it is compact, but it requires free space to unfold it. The system is supplemented with linen drawers;

- Dolphin ? mechanism for a corner sofa. By pulling a special strap, the hidden part of the structure is pulled out, which will complement the sofa seat to form a berth. It is comfortable and spacious;

- Click-clack? analogue of the “book” mechanism. The difference is that the backrest can be in an intermediate version, which allows a person to be in a semi-lying state. The transformation mechanism requires free space near the wall.

Roll-out

Click-clack

Eurobook

Book

French folding bed

Accordion

DolphinFor internal filling

In the production of cabinet furniture, kitchen sets, wardrobes and other types of structures, first of all, attention is paid to their functionality. Today, the internal fillers of furniture structures are comfortable and ergonomic. Types of internal filling for kitchen sets:

- Drainer;

- Tray for storing cutlery;

- Mesh basket;

- Rotating carousel;

- Lifting mechanism;

- Bottlemaker;

- Column;

- Bin.

The internal filling of the wardrobe is divided into three parts:

- Main? hangers and shelves;

- Top? mezzanines for long-term storage of things and hats;

- Bottom? pull-out compartments for storing documents, jewelry, as well as compartments for seasonal shoes.

In wardrobes, the maximum load on the shelves is 70 kg and allows you to store household appliances. T-shirts, jeans, shirts are stored on pull-out shelves. For things that need to be stored on a hanger, a pantograph is installed.

It is attached to the back or sides of the shelf. The pantograph can be extended manually or using the control panel. Without furniture components, it is impossible to assemble structures. The proper, uninterrupted operation and aesthetic characteristics of the product depend on them.

Video

Post Views: 108

Mounting features

Eccentric furniture ties consist of the following parts:

- stand (another name is a rod, it can be either a self-tapping screw or a screw);

- eccentric;

- futorka (performs the functions of a nut).

Sometimes the kit includes a sleeve, also known as a coupling, to screw the rod not into wood or plastic, but into it. If the diameter of the screed is large, a plastic decorative plug is added to the front side. The bushing increases wear resistance and strength - the metal part is not as loose as a hole made in the chipboard. So it is better to choose fittings with couplings to avoid breakdowns and extend the life of the furniture.

The basic principle of operation is quite simple: a coupling is inserted into a round hole on the furniture, a stand is screwed into it, and an eccentric connects them from the side. If some unsightly detail remains visible from above, then a plug is put on.

Eccentric furniture ties are also called minifix or rastex.

- If the minifix is already built into the right place, the bushing and eccentric are inserted, installation will not take much time. The only tool you may need is a flathead screwdriver.

- This type of fittings is very wear-resistant and can withstand repeated assembly and disassembly without becoming loose or losing its quality and strength.

- From the front side, the screed is invisible and does not spoil the design of the product; it can only be seen from the inside, and even here, if necessary, a plug is used.

- The ability to fasten parts at different angles (the most common options are 90, 135 and 180 degrees).

- The fastening adds rigidity to the entire structure.

- Reducing the number of spare parts, for example, if you attach the tabletop directly to the sides, drawers will not be needed.

- Long service life and ability to hold heavy weight.

How to tighten eccentrics on furniture?

Reliability, durability, attractive appearance are the main requirements for wooden cabinet furniture. An eccentric coupler is a special fastening connection that ensures that these requirements are met. It is also called "rastex" or "minifix".

Advantages of an eccentric coupler:

- increasing the strength of the connection due to the fact that the screed acts as stiffening ribs;

- ensuring a hidden connection, that is, the absence of visible fastening elements on furniture facades;

- possibility of fastening parts at different angles;

- repeated assembly and disassembly of the structure without loss of connection.

The main disadvantage that limits the use of this type of fastener is the difficulties encountered during its installation, and the cost of this type of fastener is more expensive than others.

Types of eccentric couplers

Minifix consists of two main elements:

- A rod that serves as an eccentric coupler screw.

- Eccentric - has the form of a cylindrical surface mounted on the shaft so that their axes are parallel, but do not coincide. The purpose of the eccentric is to convert rotational motion into translational motion.

Additional elements of minifix furniture that may be included:

- plug, performs a decorative function;

- a bushing (dowel, sleeve) made of plastic or metal, performs the function of a nut (manufacturers are gradually moving away from producing ties of this design).

Standard types of eccentric couplers may differ in the sizes of eccentrics and rods. The most common are eccentrics with a diameter of 15 mm, but they can be 12 mm and 25 mm, and 12.5 mm deep.

The standard diameter of the screw body is 6 mm and 8 mm. They can be length:

- 10 mm – used mainly when assembling shelves;

- 26 and 34 mm - used for fastening critical parts in furniture.

In addition to the standard screed, there are less common types:

- corner - they are two screws hingedly connected and two eccentrics; they are used to connect parts at angles other than 90 degrees, but are used infrequently, since in furniture all angles are mostly right;

- double-sided - the set includes 2 eccentrics and a double-sided connecting screw, up to 84 mm long, intended for fastening, for example, adjacent shelves located on both sides of the wall.

Depending on the material from which the fastening elements are made, the screed can be:

- plastic - used to connect small structures that are not subject to significant load;

- metal - used to connect bulky structures, such as kitchen furniture, and can be reinforced with a body into which the futurka is placed.

The leader in the production of fastening equipment, the German concern Hettich, has developed minifixes Rastex 15 (for panels 12-22 mm) and Rastex 12 (joining panels 12 mm thick). The innovation lies in the fact that the eccentrics are die-cast from a zinc alloy. They have external and internal gear locks, which improve the reliability of fastening and prevent the movement of parts during assembly.

This type of fastening, such as minifixes, is used when it is necessary to hide fastening elements, for example, on a furniture facade. Due to the peculiarities of drilling grooves for screws and eccentrics, this method is common mainly for factory installation of furniture. But knowledge of the basic principles, the availability of specialized equipment and a little skill will allow a novice home craftsman to master this type of fastening.

The main purpose of an eccentric coupler is to connect parts at right angles. This connection happens:

It is used for conjugating furniture parts of tables, cabinets, and chests of drawers. The parts are connected in the same way when installing cabinets and shelves. Experts recommend using wooden dowels as an addition, which will guide the elements being connected, and the eccentric will tighten them.

The mechanism for connecting furniture elements using a minifix without a sleeve is as follows:

- A screw is screwed into a hole with a diameter of 5 mm on the surface of one of the elements being connected.

- The second element is put on the screw with a hole measuring 8 mm located in the end part.

- An eccentric is inserted into a groove on the surface of the second element, 15 mm in diameter.

- Using a screwdriver, the eccentric is rotated 180 degrees in a clockwise direction, securing the connection. A simple screwdriver, flathead or Phillips, or a hex wrench can be used.

The principle of fastening parts with a tie to a sleeve is similar. The difference is that the hole for the base of the screw is made with a 10 mm drill, in which a plastic sleeve is attached to PVA glue, into which the screw is screwed. The remaining steps are the same as when using a minifix without a sleeve.

Assembling furniture using this method, if you have experience in such work, is simple and quick.

Let's look at how this type of fastening works using the example of assembling a chest of drawers and the chest of drawers itself.

Assembling the box

It is recommended to assemble a box with an eccentric tie in the following sequence:

- Screw the eccentric screw into the front surface of the drawer.

- Insert dowels into the recesses on the sides of the screw holes and compact them with a hammer.

- Insert the side of the box onto the dowels and rod.

- Use a hammer to help the sidewall fit tightly into place.

- Insert the eccentric into the groove in the sidewall until it stops.

- Without applying much force, turn the eccentric until it stops.

- Repeat all steps on the other side.

- Insert the bottom of the drawer into the grooves.

- Use Euroscrews to fasten the box binding.

- Use a stapler to secure the bottom.

- Tighten the Euroscrews from the side using a wrench.

- Attach the handle.

Scope of application

An eccentric tie is often used for furniture that needs to be frequently transported disassembled or stored for storage after each use (folding tables, folding sofas, etc.). Such fittings will not fail even if it needs to withstand a lot of weight - it is very durable, especially when an additional liner and body are included in the set.

Typically, minifixes are recommended for L-shaped and T-shaped fastenings at right angles, because even in such conditions they are quite reliable. Also, eccentric couplers are useful where the design implies the absence of protruding fasteners, for example, they can be used to attach a furniture façade.

In practice, such ties are used to fasten tabletops, bottoms, back walls of chests of drawers, wardrobes, pencil cases, bedside tables and other things. Another area of application is built-in furniture. Various subtypes allow you to select fittings for both large and miniature items.

Manufacturing materials

Eccentric couplers are made of both metal and plastic. Plastic split-spacer ones are better suited for small horizontal objects like shelves and for lightweight products. It is much easier to install them; just insert the rod into the continuous end and hit it with a hammer several times. However, if a lot of weight presses on them, such footers can spread out excessively and damage the chipboard: sooner or later a crack will appear, which will then spread further. To secure the plastic, it is sometimes recommended to use glue: it is poured into the hole where the coupling is inserted.

It is more difficult to screw in a metal minifix, but it will withstand, for example, a heavy kitchen set without damaging the furniture itself. Glue is definitely not required here, but countersinking is required - additional alignment of the holes. Unlike plastic, steel is not as malleable and will not conform to the shape of a recess under pressure.

When installing ties and then transporting the finished product, you need to remember that plastic will not scratch adjacent parts, but metal can. If stainless steel bushings have been selected, it would be a good idea to take additional safety precautions.

Dimensions

The sizes of eccentric couplers vary. The height of the stand can vary from 38 to 58 millimeters. The diameter is usually 12, 15 or 25 mm, the most common option being 15 mm. The ties themselves can be 5 by 50, 7 by 50 and 7 by 70 millimeters. To choose the right one, you need to evaluate the weight that it will have to withstand, as well as the size of the holes for fastenings. For example, for a small shelf a small tie is enough. But when assembling large-sized products, it is worth thinking about reinforced fastenings with an additional footing and housing.

For shelves, a rod with a length of about 10 millimeters is usually chosen, and the eccentric coupler of large furniture already requires a long stand - from 26 to 34 millimeters.

Installation nuances

You need to know how to install an eccentric coupler: if used incorrectly, it will be practically useless and will lose all its advantages. You should start with markings: put marks with a pencil or chalk where you plan to drill the grooves. The optimal distance from the edge is at least 10 mm; it should be the same on both parts being connected. The hole for the rod should not be located less than half the thickness of the eccentric from the edge. Most often, furniture purchased in a specialized store is accompanied by assembly instructions, which usually provide all the necessary recommendations. If the holes are not accurately marked, there is a high probability that the rod will dangle and the tie will be weak. Therefore, measurements must be with minimal errors.

The second step is the additive. It is very important to drill all the holes carefully, without making them through, because the quality of the result greatly depends on this. It would be wise to put a stopper on the drill you are using. Tools you will need: a drill and a milling cutter or a screwdriver. The dimensions of the drill are selected based on the declared dimensions of the rod. In most cases, a diameter of about half a centimeter is suitable to secure from the screw side. For the hole where the post is connected to the eccentric, you usually need a drill of about 8 mm in diameter, but it all depends on the specific mount.

Finding out what size the hole for the eccentric should be is quite easy: the height of the head is about 3 mm, and the same amount is needed to grip the head. That is, you need to subtract 6 mm from the total length of the rod.

Installing a standard size eccentric tie will require a drill of 15 mm in diameter, this will allow you to fasten the parts without a gap - it will be stronger and more aesthetically pleasing. The best tool is a milling cutter. For more accurate markings, stencils and even a special conductor are used; if desired, they can be purchased at the store. If you have to work with wood, it is better to take a special drill specifically for this material, otherwise during work there is a chance of severely damaging the appearance of the product.

Additive for eccentric coupler

Adding an eccentric tie is the most difficult stage of furniture assembly. Here it is important to accurately make all the holes, since the quality of the connection of the parts depends on this. The additive is performed using three cutting tools, two drills and a milling cutter. Holes for eccentric couplers can be made using a drill, screwdriver or router. The latter allows you to perform the additive with maximum accuracy.

The diameter of the drill for the eccentric coupler is selected based on the size of the rod. For most types of rods, the diameter of the drill for securing the rod into the part is 5 mm (from the screw side). For the hole through which the rod is connected to the eccentric 8 mm. However, sometimes you come across a reduced rod, in which case a drill with a diameter of 6 mm is used to tightly fit the eccentric coupler.

A milling cutter is used to install the eccentric. The cutter for the eccentric coupler also has another name: Forstner drill. For a standard eccentric, a drill with a diameter of 15 mm is used. Such hole dimensions allow the eccentric to be seated precisely without any gap, which has a positive effect on the strength of the connection between the parts.

Drilling holes can be done manually or you can use a ready-made jig for an eccentric coupler. Using a jig allows you to make holes very accurately with a conventional drill. However, it is often difficult to purchase a jig and you have to make all the holes using a conventional drill. In this case, a drill for an eccentric tie should be chosen special for wood. It is different from the drills that are usually found in every home. Thanks to its special design, it will allow you to drill all the holes correctly.

Using the furniture jig shown in the figure above, you can complete all the markings and make all the holes for the eccentric coupler. The procedure for working with the conductor is as follows. First, the jig is installed on the part and the location of the groove for the eccentric is marked through the corresponding hole on the jig. Next, a cutter is used to make a hole for the eccentric. A marking pin is inserted into the corresponding hole on the jig. Then install the jig on the part and drill a hole for the eccentric rod. So, in several operations, a very precise additive for the eccentric coupler is obtained.

Reliability, durability, attractive appearance are the main requirements for wooden cabinet furniture. An eccentric coupler is a special fastening connection that ensures that these requirements are met. It is also called "rastex" or "minifix".

Advantages of an eccentric coupler:

- increasing the strength of the connection due to the fact that the screed acts as stiffening ribs;

- ensuring a hidden connection, that is, the absence of visible fastening elements on furniture facades;

- possibility of fastening parts at different angles;

- repeated assembly and disassembly of the structure without loss of connection.

Eccentric coupler - what is it?

An eccentric coupler consists of parts of fittings that must be connected using special fasteners. An eccentric tie is the most economical option as it can be used several times.

It is characterized by strength, reliability and a high level of wear resistance, which significantly extends its service life.

An eccentric coupler consists of a drain, which has a T-shaped head, and a special clamp, which is called an eccentric. The eccentric can have different diameters:

- 12 millimeters;

- 15 millimeters;

- 25 millimeters.

The eccentric coupler is characterized by invisibility from the outside, which provides a lot of convenience during its use. Thanks to the use of minfix, the number of used products is significantly reduced.

The eccentric coupler includes a cylinder. Its installation is carried out in a special hole, which is located in the part. This part must be attached to the main part of the screed.

Also, the eccentric coupler consists of a plug, with the help of which the end surface of the eccentric is closed.

How to attach an eccentric tie?

The eccentric tie is fastened using a drill, cutter, ruler, screwdriver, awl and pencil. Three holes are made in the parts intended for connection.

All these holes must have different sizes. Next you need to make a hole of 5 millimeters. A drill is used for this purpose.

Two holes are also made in another part. A cutter is used for this purpose. The thickness of the hole must fully correspond to the thickness of the eccentric. This will ensure it fits as accurately as possible. You need to make another hole at the end of the part using a drill.

At the last stage, you need to screw in the eccentric rod. The second part is mounted on this device. Using a minifix, this structure is clamped.

You can also assemble a minfix with a plastic sleeve. This action is performed in the same way as installing a metal minfix.

How to use an eccentric coupler?

An eccentric coupler is used to connect various parts. An eccentric tie is used to fasten the tops of various tables, chests of drawers, cabinets, etc.

To use this type of tie, you need to drill two holes in the top of the furniture leg. This action is performed in order to install the clamps.

Similar holes must also be drilled on the end of the furniture. Thanks to this action, you can get an end-to-end channel.

Similar holes must be drilled in the tabletop, into which a rod with a T-shaped head is screwed. The furniture leg must be attached to the tabletop so that their holes coincide.

Next, you need to push the rod through this channel. The final step is to rotate the eccentric. This is done clockwise. An eccentric tie is a fairly high-quality fastener that is widely used for furniture.

Why do you need a floor screed? – see the answer to the question here

When performing this type of screed, it is necessary to position the holes in the parts as accurately as possible. Thanks to this, the tie rod and eccentric are positioned as correctly as possible. Otherwise, you can damage both the door lock and the product itself.

And also watch useful video material about the eccentric coupler:

As mentioned above, to install an eccentric coupler, three holes of different diameters must be made in the parts to be connected.

Source: glavspec.ru

Additive for eccentric coupler

Drilling holes, or as they say, adding an eccentric screed, is the stage on which the quality of fastening elements of furniture construction depends. The process of drilling grooves itself is accompanied by difficulties. It is important not only to observe all dimensions, but also to take into account that the groove for the eccentric should not be through. To drill it, you need to use a special Forstner drill and a depth stop when drilling. Doing this kind of work on your own for the first time is not easy.

- router and Forstner drill;

- drill with two wood drills (diameter 5 mm and 8 mm);

- screwdriver or screwdriver.

To install such a connection, you need to drill three holes of different diameters and depths. The mandatory procedure when drilling slots for furniture minifixes is as follows:

- Make a non-through groove in the surface of one of the fastened elements for installing an eccentric. Standard groove dimensions: diameter 15 mm and depth 12.5 mm. Its center is located from the end of the part at a distance corresponding to the length of the rod. It is drilled out with a Forstner drill, thanks to which the eccentric can be placed in the groove without gaps. To accurately drill such a groove, use a depth stop. Otherwise, there is a possibility of damaging the surface of the furniture if the drill goes through.

- Drill a hole for a screw in the end of the same element perpendicular to the groove for the eccentric. If it has a diameter of 8 mm, then the hole should have the same dimensions. The optimal distance between the center of the hole in the end for such a rod and the surface of the furniture element is 8 mm (the middle of the chipboard thickness).

- To strengthen the screw, make a blind hole (12 mm deep and 5 mm in diameter) in the surface of the second mating part.

Another way to make grooves for the additive is to use a ready-made jig. It will make marking and drilling easier. When working with a conductor, the following procedure is recommended:

- Install the jig on the part, mark the location of the groove for the eccentric through a special hole in the jig.

- Use a Forstner cutter to make a groove for the eccentric.

- Insert a marking pin into the hole in the conductor. Place the jig on the end of the part and drill a hole for the screw.

- Make an installation hole for the screw in the second part.

Thus, an eccentric tie is the optimal option for fastening the façade parts of cabinet furniture. In home production, its use is somewhat limited due to the difficulty of making grooves for the structural elements of the screed. But if you have specialized, affordable devices (conductor, milling cutter), even a novice master can cope with this task. An eccentric tie is indispensable if it is necessary to ensure the inconspicuousness of fastenings and during frequent disassembly of furniture.

If you find an error, please select a piece of text and press Ctrl+Enter.

An eccentric coupler is a type of connecting fittings. It is durable and reliable, unnoticeable, and can be used repeatedly. Today, EtoDom experts will talk about the installation, advantages and types of eccentric screeds.

Content:

Features of eccentric furniture screeds, installation rules

In the production of furniture, various types of fasteners are used, which ensure the reliability and durability of the structure. The eccentric furniture tie has become the most common in recent years. It is also known as “minifix” or “rastex”. An eccentric tie allows you to fasten elements at different angles, assemble and disassemble products several times. Furniture assembled using such an element is incredibly durable.

Eccentric coupler furniture installation, furniture assembly, instructions

Furniture eccentric screed is one of the types of fasteners used in furniture production. It allows you to hide the places where parts are attached, which has a positive effect on the design of products. Another advantage of an eccentric tie is that it allows you to repeatedly assemble and disassemble furniture without losing the strength of the connections, for example, during transportation. However, for all its advantages, it is more difficult to install than other types of furniture fasteners. Therefore, it is very important to correctly follow all installation instructions provided in this article.

Content

Assembling furniture with eccentric couplers is performed in the following sequence. The coupler consists of two parts: an eccentric and a rod. The operating principle of this fastener is very simple. The rod is attached to one part, and the eccentric to the other. Next, the parts are connected and the eccentric is turned, which fixes the parts. Assembly and disassembly of furniture using eccentric ties is very quick and easy, which is a great advantage of this type of fastener.

An eccentric coupler can have different sizes of both rods and eccentric. The most common is a 15 mm eccentric. The rod can have sizes of 10, 26, 34 mm. The size of the eccentric coupler is selected based on the application conditions. So, for shelves, a rod with a length of 10 mm is suitable, and for connecting furniture parts, choose 26 or 34 mm.

Scope of application

Furniture fasteners are used for L-shaped and T-shaped connections. Minifixes are in demand when assembling cabinets, tables, and chests of drawers. They connect the lids and bottoms of cabinets, as well as the tops of computer and dining tables, bedside tables and chests of drawers. In addition, eccentric furniture ties are used to fasten parts where it is not possible to drill holes. For horizontal elements, such as shelves, it is more convenient to use plastic ties. Bulky structures are assembled using reinforced eccentrics. Such fasteners are placed in the housing and contain an additional fitting.

The furniture is connected in such a way that the minifixes remain almost invisible. They can only be seen from the inside of the product. This point can be considered an advantage of this type of fasteners, since they do not spoil the appearance of the furniture. The eccentric tie makes assembly of products simple, quick, and also adds additional rigidity to the entire structure.

Video: installing a furniture eccentric coupler

Reliability, durability, attractive appearance are the main requirements for wooden cabinet furniture. An eccentric coupler is a special fastening connection that ensures that these requirements are met. It is also called "rastex" or "minifix".

Advantages of an eccentric coupler:

- increasing the strength of the connection due to the fact that the screed acts as stiffening ribs;

- ensuring a hidden connection, that is, the absence of visible fastening elements on furniture facades;

- possibility of fastening parts at different angles;

- repeated assembly and disassembly of the structure without loss of connection.

The main disadvantage that limits the use of this type of fastener is the difficulties encountered during its installation, and the cost of this type of fastener is more expensive than others.

Materials and equipment

The eccentric coupler consists of 3 elements: a stand, an eccentric and a fitting that acts as a nut. There are several types of fasteners, which can be divided into groups depending on the material of their manufacture, the length of the stand, diameter, size, type of fastening of the self-tapping screw and fitting.

If you often disassemble and reassemble furniture, this type of fastener will be the best option. It is ideal for products made from chipboard and chipboard.

Eccentric furniture couplers can be metal or plastic. The material depends on the scope of application of the interior items. For example, when assembling kitchen sets, metal fasteners are used, while plastic fasteners are suitable for small items. The racks can be short up to 38 mm and long up to 58 mm. There are minifixes with a diameter of 12, 15 and 25 mm. Parts with a diameter of 15 mm are the most common. For the latter, the largest ones, special plugs made of polymer material are provided. The sizes of the ties are as follows: 5x50, 7x50, 7x70 mm. This allows them to be used when assembling almost any type of furniture.

Furniture fasteners: eccentrics, corners, dowels

Search the site:

Online designer for independent 3D modeling of a cabinet!

Before the creation of modern technologies and fittings, furniture was made by carpenters. Lock joints, tenons, dowels, wedges were used as fasteners for connecting panels together; the same “fittings” were used in the construction of wooden houses, etc.

Glue was used to make the joints rigid; naturally, there was no talk of any ideal precision in the joints. Only a virtuoso, using tools such as a saw and a chisel, could more or less accurately maintain the dimensions.

Nowadays, such connections of parts are specifically used to give furniture an “antique” style. This article describes the main fasteners and fittings that are used in wardrobes, dressing rooms, hallways, etc.

Dowel

This type of fastening is rarely used independently; it is used only to provide rigidity in conjunction with eccentric couplers.

its function is to prevent the panels from moving relative to each other and giving additional rigidity to the fastening. Used in conjunction with an eccentric coupler. It is made from hard natural wood and has a cylindrical shape. This is a very simple and cheap part that has been used in wooden joints since time immemorial.

Screw tie

A screw tie consists of a screw and a barrel; they are used to secure the end of one panel to the face of another. For example: attaching a shelf to a side panel.

This is a very strong fastening due to the large tightening stroke. The only drawback of this fastener is that the screw head is visible from the front of the panel.

You can, of course, close them with special plugs, but this is also not a panacea. The plugs on the outer panel of the cabinet do not look aesthetically pleasing.

Installing this type of fastener requires skills; beginners may encounter such problems as aligning the holes of the barrel with the hole in the end of the shelf, and it is not so easy to pull out an unnecessary barrel from its nest.

But the inconvenience during assembly and aesthetic errors are more than compensated for by the reliability and durability of the connection. connections!

Conical coupler

Conical tie is often used for fastening thick chipboard panels (25 mm, 38 mm)

One of its advantages is the absence of visible caps on the front side of the panels. Unlike the screw in a screw tie, the rod used in a tapered tie is screwed into the panel. The tie itself has 2 holes, one for the rod, which is screwed into the panel layer, the second for the screw of the conical tie.

The disadvantage of this type of fastener is that the tightening stroke is not long; under heavy loads, the holes for the rod screw may become loose over time, and then the tie will simply stop working!

Furniture corner

Quite a simple type of fastener, easy to install. Does not require any additional holes in the panels for its installation. There are both metal and plastic options.

Quite a durable type of fastening and inexpensive in price. The disadvantages are that it is visible and does not look aesthetically pleasing, especially if it is made of plastic. But this is the main type of fastening in built-in furniture, since eccentrics and Euroscrews are used only for fastening chipboard shelves to each other.

Euroscrew

This fastener is often used for assembling kitchen furniture modules and in economy class furniture. Just like with a screw tie, Euroscrew heads or plugs are visible on the front side of the side panel of the cabinet.

It screws into the end of the shelf with a pre-drilled hole. This screed also belongs to the economy class. To install it, 2 holes are drilled - into the end of the shelf and into the face of the part. They are attached perpendicular to each other. The most commonly used euro screws are 7 mm in diameter and 50 or 70 mm in length.

This screed has 2 significant drawbacks:

Firstly, the outer side of the cabinet, if there are many shelves behind it, as a rule, is all “disfigured” with caps or Euroscrew plugs. Therefore, these fasteners are used in economy furniture; in kitchens, this drawback is hidden thanks to the cabinets standing in a row.

Secondly, furniture assembled with euroscrews cannot be disassembled and reassembled more than 3 times, since screwing the tie into the end of the shelf destroys its internal structure.

Eccentric coupler

One of the most popular types of fasteners today. All high-quality furniture is assembled on an eccentric screed (minifixes). Its operating principle is as follows: an eccentric rod is screwed into the face of the part to which the other panel will be attached at the end, into which, in turn, through the end of the other shelf it is screwed into the eccentric itself, then the eccentric turns the rod into itself.

An eccentric tie is always used in conjunction with a wooden dowel, which was described earlier. The dowel provides additional rigidity to the assembly and prevents the fastened panels from moving relative to each other.

Furniture assembled on this screed can be disassembled and assembled an unlimited number of times! There are different diameters of the eccentric itself: 25, 15, 12 mm.

Since the eccentric itself is visible on the side panel, plugs are provided for it to match the color of the panel. One of the disadvantages is the weakening of the coupler in case of spontaneous rotation of the eccentric.

To avoid this, some hardware manufacturers have provided notches directed in the opposite direction from its rotation during installation, which enhances adhesion.

Types of eccentric couplers

As practice shows, furniture is assembled and disassembled with great difficulty if all the fasteners in it are the metal tie described above. Let’s say that in order to remove one shelf, you practically need to dismantle half the cabinet.

For horizontal parts (shelves) it is more convenient to use “plastic” eccentrics. Their operating principle is the same as that of a metal eccentric coupler. The only difference is that the eccentric, located in the shelf, fits onto the rod screwed into the face of the sidewall from above and there is no need to disassemble half the cabinet for this. In some factories, this type of fastener is called a shelf holder, since it is intended only for horizontal parts. Horizontal shelves assembled using these ties further tighten the joint, which increases the rigidity of the entire furniture frame.

Here, the metal eccentric itself is located in a housing, most often in a plastic one. Repeated dismantling and installation of furniture does not lead to wear of the joints.