Design Features

Frameless sofas are a unique type of product that eliminates the use of a rigid metal or wooden frame. At the same time, the design perfectly retains its shape and is no different from ordinary furniture. A frameless sofa consists of several large modules that are interconnected.

- External case.

It is often made of dense fabric that can withstand long-term loads without losing its appearance. - Internal case-frame.

It is this part that gives each element of the sofa its shape. - Filler.

As this attribute, polymer balls of small diameter are used, which retain their shape for a long time. The size and type of filling is selected individually for each type of sofa, depending on its purpose.

Almost every product model is equipped with small holes (perforations) that promote better air exchange. This keeps the sofa in good condition, preventing mold from forming. Also, the material does not absorb odors and does not rot, which allows you to extend its service life.

Sofa fillers

The most common fillers are:

- holofiber;

- polyurethane;

- foam;

- padding polyester

In addition to the above, there are many other materials used as filling.

Foam rubber

This is the most famous and inexpensive sofa filler. It has been used for several decades.

The main disadvantage of this filling is its fragility. After just a couple of years of active use, unevenness appears on the sofa and the filling has to be changed.

Sintepon

This material is considered one of the most optimal filler options. It combines reasonable price and good quality.

Polyurethane

An alternative to synthetic winterizer is polyurethane. It retains its shape well and has a long service life.

When choosing a sofa with polyurethane foam, pay attention to the elasticity of the filler. Polyurethane foam should not be too pliable and soft, otherwise it will quickly lose its characteristics.

Holofiber

This is one of the best modern artificial fillers. It is able to maintain excellent shape even under heavy and prolonged loads.

Sofas can be made with metal springs. The properties of such a filling depend on the number of springs, their material and fastening.

It is best to choose a sofa from a large manufacturer. In this case, you can receive free repairs and maintenance of the product during the entire warranty period.

We hope the article was useful to you and now you can easily choose a good sofa. Happy shopping!

Design secrets

The construction of such furniture is a simple operation that requires the formation of a fabric frame. This allows you to give the sofas any shape - from a simple horizontal platform to a corner bag. It should be noted that the cost of this product is slightly less than other products. At the same time, you can update the design of a frameless sofa almost every month. To do this, you just need to sew a new cover, which you then put on each of the soft blocks. Please note that you can combine different designs of a single element in this way.

Advantages of furniture

According to customer reviews, frameless sofas are a unique opportunity to diversify your interior. Furniture of this type has many positive aspects:

- Light weight.

This is achieved by removing the frame, as well as using a lightweight polymer filler. The weight of sofas of this type can be only 25-40 kg, depending on its size. Even a woman can move such a product, which makes it easy to change the location of the furniture after a certain time. - Easy to care for.

All sofas are equipped with removable covers, which can be easily removed for cleaning or replacement if necessary. In this case, the duration of production of a new pattern does not exceed several hours. - Long service life.

All furniture components are made from high-quality and dense materials that can easily withstand constant loads. As for the filler, it also retains its shape and elasticity for a long time, and if necessary, it can be easily replaced. - Comfort.

The shapeless frame perfectly adapts to the contours of the human body in any position. This allows you not only to sit, but also to lie on the sofa without exposing your body to unnecessary stress. - Unique design.

Modern sofas are made of eco-leather, which allows them to fit into almost any style of home. Manufacturers bring to the market furniture of various colors and shades that will appeal to even the most sophisticated gourmets. - Low price.

The cost of this product varies widely, depending on the material used for exterior decoration. - Hygiene.

Almost all types of sofas are equipped with covers that repel dirt. If the material does become dirty, this does not prevent the owner from simply replacing the surface with a new one. - Safety.

The absence of hard corners allows children to play on them without the risk of hitting them.

Wooden frames

Wood is rightfully considered the best option. It is distinguished by durability and environmental friendliness. The structure can easily serve faithfully for 20 years or more.

To create the frame, different types of wood are used. Increased strength is demonstrated by oak, beech, walnut, and ash. The values for pine and other conifers are lower due to their increased softness. There is also furniture with a mahogany base, but its price is off the charts.

The raw materials are screened for knots and various damage, dried well (the permissible moisture content should not exceed 8%), and treated with special compounds. Such means should protect the material from pests, mold and rot.

The frame elements are connected to each other with special bolts.

A solid wooden beam is intended for the seat. The glued variety is usually installed in the sidewalls. It is unacceptable to replace the latter with separate bars. However, unscrupulous manufacturers practice the following scheme. The wooden elements are wrapped in cardboard and secured with nails or metal staples. The use of such a design negatively affects the characteristics of the product.

The advantages of a wooden base include:

- durability;

- orthopedic properties;

- health safety;

- positive effect on the indoor microclimate.

The disadvantages include significant cost.

Before purchasing, you should carefully inspect the frame to ensure its quality. Signs of an obvious marriage are:

- increased knotiness;

- cracks;

- the presence of mold, rot and dark spots of unknown nature;

- areas damaged by harmful insects;

- fixing parts with glue and screws.

Models with a plywood frame have good performance. Manufacturers promise a service life of at least 10 years for such products. You will be pleased with the light weight and more affordable price. However, if the length of the sofa exceeds the dimensions of standard blanks, then a wooden beam will be required for the bottom bar.

Plywood is obtained by gluing sheets of natural veneer, alternating layers with transverse and longitudinal fiber directions. Thanks to this, the strength characteristics are enhanced. The material does not show a tendency to deform, since moisture is removed almost completely during the production process, and is safe for others. The optimal sheet thickness is 12-25 mm.

Negative sides

Frameless furniture only at first glance seems universal and practical. Still, sofas of this type have several significant disadvantages:

- Over time, the filler loses its shape,

which leads to its gradual compaction. Therefore, to maintain optimal volume, you should periodically replenish the sofa with new balls. - All sofas are characterized by a low seating position

, which is not always convenient for older people, since it will require additional effort to rise. - The orthopedic characteristics of the structures do not allow the use of such furniture for sleeping.

The rigidity of the sofa frame is minimal, making it impossible to achieve an optimal level of spinal support. After periodic use of such furniture, back pain may begin.

It should be understood that frameless furniture is a large soft pillow that is used not only for the head, but also for the entire body. It is recommended to use it only as additional attributes. If you decide to use sofas for sleeping, supplement them with special orthopedic mattresses. It is important to choose them correctly with the help of experienced specialists.

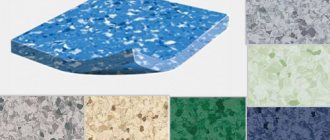

Materials used

The production of frameless furniture involves the formation of fabric bags to be filled with special balls. Several products are used as filler:

- Wood shavings.

Often, for such furniture, waste from pine or spruce is used, which are not so damaged by rodents and emit a healing aroma. - Down or feathers.

This filler is quite rare, since the cost of such a sofa will be much higher than its analogues. - Polymers.

Many artificial materials, such as foam, can be used as filler. Some models are made from foam rubber, but it is not able to hold its shape for a long time. The most popular filler is polystyrene foam, which holds its shape well and is safe for human health.

Many types of fabrics are used to make covers:

- velor is hairy;

- flock is resistant to fading;

- jacquard is characterized by high strength;

- eco-leather resists the effects of water;

- The tapestry has high durability and a variety of designs.

Types of models

Frameless sofas are a complex of several individual modules that are interconnected. This allows you to give them a classic shape. Today, both regular and angular modifications are available on the market. Each of them has its own advantages and disadvantages. Among all this diversity, several popular models should be highlighted:

- "Marrakesh".

This type of sofa resembles a large soft bed. The width of the sofa reaches 2 m, while the depth is 1 m, the back also protrudes by 1 m. The covers are made from various materials, among which eco-leather is considered the main one.

- "Modern".

A distinctive feature of this sofa is its red color. The design is characterized by a small width - up to 150 cm with a seat height of 45 cm. The weight of the sofa is only 5 kg, which makes it easy to place it anywhere in the room. Expanded polystyrene is used as filler.

- "Rook"

. The product is made in a classic style and is distinguished by the presence of a special platform. Manufacturers claim that the sofa can last up to 10 years without the need to replace the filling. All types of fabrics that the customer desires are used as materials for the manufacture of covers. The length of the structure is almost 2 m, while the width is only 1 m. Please note that the sofa platform folds out and can be converted into a sleeping place.

Do-it-yourself frameless furniture is: an original book-bed, a sofa made of foam modules, a pear-tent chair. Make them yourself.

Frameless furniture: types, materials used

By making such items with your own hands, you can furnish your children’s room, bedroom, or living room with them. If you have a summer house, then place these things on the veranda to relax here in a cozy atmosphere.

Here are the types of frameless furniture that exist:

- square or cylindrical ottomans;

- bean bags;

- balls that are shaped like a circle;

- chair cushions;

- pyramids that perfectly support the head and back;

- sofas consisting of several;

- models in the form of toys, for example, animals, flowers;

- gift option - heart.

To sew frameless furniture, textiles are used; if it is a sofa, then the filler here is thick foam rubber.

The same is suitable for creating heart-shaped models and cushion chairs. For the rest, small foam balls are used, which fill the inside of a particular piece of furniture by 2/3. The filling is placed in the inner bag, and a decorative outer bag is put on top, for which durable fabrics that hold their shape well are used.

For upholstered frameless furniture, it is better not to use pile material, which collects dust and wool.

The following types of material are perfect for the outer case:

- jacquard;

- flock;

- durable cotton;

- natural or artificial suede;

- Oxford;

- leatherette or genuine leather.

For one product, you can sew several outer covers, which can be easily removed using a snake lock. Then in winter you can put a warmer cover on it, and in summer use a light cotton one.

The positive properties of granular foam used as filler are that:

- it is very light, so such products are easy to carry or move;

- an armchair or ottoman quickly takes the shape of a sitting person;

- such balls have high thermal insulation, so products made from them can be used even in winter;

- Unlike frame models, it is impossible to get hurt on the data (there are no sharp corners), so this furniture is perfect for a children's room.

It's time to start master classes directly to learn how to make some furnishings.

This product consists of several blocks. Here's what you'll need to create it:

- thick foam rubber;

- furniture fabric;

- PVA glue;

- reinforced threads;

- scissors;

- ruler;

- sewing machine;

- furniture stapler;

- tape measure.

The seat consists of two blocks, each created according to the same principle.

To do this, cut out 3 identical rectangles of foam rubber and sew these parts together. According to their size, you need to cut out and sew the covers, stitch them at the corners. Here you will put foam filling on your hands, sew one side with a hidden seam. You also need to cut two sheets of foam for the back and 2 for the armrests. You also need to sew covers for these parts. We begin to assemble a frameless sofa. Fasten two pillows using a furniture stapler. If there is no such tool, then sew them on your hands so that you can fold them. Attach the back to them; you can additionally fix it with PVA glue. In the same way, attach the two small side panels. If you want to make a folding sofa like a chair-bed, then make the upper block of the seat smaller than the lower one, and sew a fabric loop on the edge. You will pull on it to unfold the sofa.

Such a product can be made one-piece by combining the backrest with the seat. The cover consists of a rectangle that covers the back, seat, back and bottom. Large sidewalls need to be cut in the shape of the letter L in a mirror image. Each of them is sewn to a given rectangle of fabric. The filler is also foam rubber. Here's how you can quite easily make a frameless sofa with your own hands. Make other pieces of similar furniture, for example the following.

What is so attractive about frameless furniture?

Firstly, this is, of course, originality. After the stumps and stones on which our not very civilized ancestors sat, after the chairs, tables, armchairs, beds of the civilized world, made of wood, metal or plastic, something radically different from both appeared. Secondly, convenience and comfort. This type of furniture takes all the curves of your body, and all your muscles relax. A great way to relax. Thirdly, safety. You cannot bump into frameless furniture and get injured. This is especially true when used in children's rooms. Fourthly, environmental friendliness. The filler is a hypoallergenic substance and does not emit harmful substances. Other materials used are also hypoallergenic. Fifthly, creativity. The flight of imagination when creating frameless furniture is limitless. You can use different materials or combinations thereof, create a variety of shapes that would be problematic to create when using traditional materials, you can use filler balls of different sizes, etc. and so on. Sixth, mobility. Frameless furniture is light - 5-6 kg, so it is not difficult to move it from place to place. When transporting, it takes up minimal space. And this is just a small part of the advantages of frameless furniture. Anyone can find many more advantages. And one more advantage of frameless furniture. Any housewife can make it. Now we will demonstrate this to you.

DIY pear chair: pattern and description

A stylish and comfortable product quickly takes the shape of the person sitting in it.

You can wash the outer cover of this chair periodically to keep the chair clean. To sew it, you will need:

- fabric for the top and inner cover;

- paper to make a pattern;

- filler in the form of foam balls;

- 2 zippers;

- related accessories;

- sewing machine;

- scotch;

- plastic bottle.

To make a bean bag chair you will need a pattern, it is very simple. As you can see, for the fabric base you will need a piece of fabric measuring 2 meters 50 cm with a width of 1 meter 40 cm. The diagram shows how to arrange the parts to save fabric. Cut:

- 6 pear-shaped wedges;

- 2 parts in the form of a trapezoid with rounded smaller sides;

- 2 semicircular bottom elements;

- hexagonal top;

- rectangular handle to carry the product.

This cutting is done on the main fabric, the inner cover is created in the same way.

Here's how to make a bean bag chair. With your own hands you will connect the pear-shaped parts and grind them down. Then the bottom elements are sewn together; they need to be stitched to the lower sections of the pear-shaped wedges. Create an inner cover in the same way, leaving space on the side for zippers, which you then sew in. Place one bag inside the other.

The inner case is 2/3 filled with polystyrene balls. To pour them into the chair, first place a large bottle with the bottom cut off on the bag of this stuffing. Attach with tape at the bottom. Insert a knife through the neck, make a cut, and the balls will begin to fall out into the container. Then you need to turn it over and lower them into the pear chair. You can cut out double front and back paws, bear ears, and sew them onto a finished plain product. Cut out a round muzzle of the animal from the same fabric, draw eyes, nose, mouth with indelible paints, or sew on facial features, having previously cut it out of dark fabric. You will get this charming bean bag chair in the shape of a bear. It will be comfortable for a child of any age. For infants, this product is placed horizontally, the baby will sleep in such a cozy chair.

DIY bag chair: patterns, selection of fabric and filling

A beanbag chair is an easy-to-make and stylish frameless furniture. It is quite possible to do it on your own.

To do this, you will need a little patience, the necessary materials and a desire to understand all the intricacies of the process.

Manufacturing techniques, useful recommendations for choosing fabric and filling, common patterns - read about all this in the presented review.

Types of frameless furniture

There are a huge number of options for frameless chairs and sofas. The most common are pear, banana and ball. There are also samples in the form of watermelon, cube and tablet.

Full-fledged sofas are more technologically advanced in production. In the interior they look impressive and can be either solid or consist of separate blocks. The common shape of such sofas is straight. But there are also angular models.

Having decided to make such original upholstered furniture, you can get creative and come up with your own version. But first, you should consider well-known models and patterns for them, and then, by analogy, recreate your design.

Fabric for upholstered furniture

What fabric will be needed for making? For the top cover - any furniture fabric:

- Furniture velor.

- Chenille.

- Jacquard.

- Leatherette.

- Artificial fur,

- Nylon.

- Velveteen.

- Flock.

For the inner cover, choose a denser material:

- Blended fabric.

- Calico.

- Raincoat fabric.

- Satin.

In addition to fabric, you will need zippers of appropriate sizes, lavsan threads, and Velcro to connect the upper and lower covers.

Beanbag filler

The most common filler for frameless furniture is polystyrene beads. This material is environmentally friendly, durable and moisture resistant.

Chairs filled with polystyrene balls can be used in wet areas such as a bathhouse, a swimming pool or a terrace. And this is possible due to the low hygroscopicity of the filler.

The granules shrink over time. Once every few years, top up to maintain the desired shape of the product.

Expanded polystyrene balls are extremely volatile and easily electrified. If they enter the respiratory tract, they can cause serious damage to health. When working with it, it is recommended to use a respirator.

Patterns for a bean bag chair

Let's look at three common cuttings:

| The bean bag chair will consist of six identical wedges (marked with the number 1 ) with a height of 1200 mm and a size at the base of 450 mm. The top pattern is a hexagon (marked with number 2 ) with a height of 182 mm and a width of 210 mm). The bottom consists of four parts: two parts each, marked 3 and 4 . |

| Rusha chair: 1 ) The main part combines the front, back and side. 2 ) Upper part. 3 ) Bottom. |

| To sew a ball chair you will need 20 hexagons and 12 pentagons. |

How to sew a bean bag chair

As can be seen from the patterns discussed above, making a bean bag chair yourself with minimal sewing skills is not a very difficult task.

To make a pear chair you will need three parts:

- Main part.

- Top part.

- Bottom.

The details of the upper and lower covers are made using the patterns. into the inner cover from side ( b ). A long zipper is sewn into the outer cover from the long side ( a ). The covers are secured to each other with Velcro.

After both covers are ready, the inner one is filled with polystyrene foam through a funnel. The funnel is made of thick paper, and its narrow edge is inserted into the inner capsule bag. The process is completed by filling in the required number of balls. During the filling process, some of the granules may spill onto the floor, so after work, thoroughly vacuum the room.

To sew a beanbag chair according to the given pattern you will need:

- Fabric for the outer cover measuring 2500 x 1400 mm (the same amount of fabric is needed for the inner cover).

- Two zippers - 1 m and 40 cm.

- Filler.

- Velcro 10 x 5 cm.

- Durable reinforced threads.

You need to start working by making a paper pattern for the pattern. Then the pattern is placed on the fabric, and the necessary fragments are cut off.

The preparations are completed. Now you need to fold two wedges with the right side inward and sew them together, leaving an allowance of 1 - 1.5 cm. The remaining wedges are sewn together in the same way and the zipper is installed.

Stitching is done on the front side, catching the allowances. Then the bottom and top of the bag are sewn on. All of the above manipulations must be carried out with the inner cover.

Having assembled the two covers together, the bag is filled with polystyrene balls using a funnel.

History of frameless furniture

In 1968, three young architects from Turin: Piero Gatti, Cesare Paolini, Franco Teodoro approached the management of the Zanotta furniture factory with an innovative idea for the production of a frameless bean bag chair. The foresight of the factory director allowed this product to enter mass production and become widely known throughout the world.

As representatives of “anti-design,” the creators of frameless furniture were critical of the development of modern technologies and consumer sentiment. They affirmed the theory of “escape”, and through provocative actions they wanted to show that the logical development of rationalism leads to absurdity. The bean bag chair (“Sacco”) has become a classic example of “anti-design”.

The bean bag chair is impeccable. It is very pleasant to sit on it, as the filler easily takes a shape that is convenient for the person sitting. By deciding to buy or make such frameless furniture, you will get the best place to relax and an original element of interior design.

Source: https://poweredhouse.ru/kreslo-meshok-svoimi-rukami/

Frameless book bed

If you like frameless furniture, consider the following piece of furniture.

This textile product was invented by the Japanese designer Yusuke Suzuki, but our domestic needlewomen will recreate it if desired. To do this they will need:

- dark dense fabric;

- light cotton fabric;

- synthetic sheet filler;

- foam;

- sewing machine.

Making master class:

- The dark fabric will become the binding. Cut out two rectangles from it, one will be the bottom, the second will be the top part of the cover.

- This size, but without seam allowances, you will need foam rubber. First, connect the top and bottom of the binding, folding them right sides together, stitch along the edges. Leave one side unstitched. This is where you will put the foam.

- If you don't have a sewing machine or it's difficult to create such large pieces on one, then sit on a clean floor and sew the edges on your hands using a needle with strong threads. In the same way, you will make “sheets” for a book-bed, but from white cotton material and you need to fill them with padding polyester, holofiber or a similar sheet-shaped synthetic material.

- Place the created elements on the binding, as you can see, on all sides they are about 10 cm smaller than it. Sew in the center on the hands.

This book bed is an excellent sleeping place for two children. Each of them will lie on one “sheet”, this will be a sheet, and will be covered with a second “sheet”.

If you want to create a small bed, then sew a soft mattress and make it out of corrugated cardboard. Decide on the width; of this width you need to cut a rectangle from this material, using a construction or stationery knife. It should be much longer than the desired length of the bed, since you will fold this blank like an accordion.

When it's time to put your child to bed, place this part on the floor, it will take the desired shape on its own. Place a rectangle of cardboard on top, which will become the base of the bed. All you have to do is put your sleeping gear here and you can rest.

But not only kids, adults can also comfortably sit on this product. But for people with a large weight, it is better to use not one rectangle, but many small ones, connecting these sections together with tape. When disassembled, they will turn into a convenient shelf for books, newspapers and magazines. If you like creative beds like these, make another piece of upholstered furniture that resembles a brush. Make a base for it. This blank is made of fabric in the form of a bag. The corners are turned on the wrong side and sewn up. Leave one edge free for now; insert a rectangle of thick foam rubber through this hole.

Now you have to create a lot of “lint”. To do this, cut foam rubber into bars of the correct shape. Each of them is covered with fabric according to the principle that was just described.

Here's another soft bed. It is created from separate modules. Large buttons on the legs, pre-covered with the same fabric, are sewn onto the sides. To connect two modules, just put a rope tied into a ring around them.

Frameless transformable chair

It is unusual and perfect for a couple.

There are two seats connected to each other by thick fabric folded in half. It is fixed using buttons. This product will quickly turn into a small two-person tent. It is enough to lift the fabric and fix it in this position, again using buttons.

Kids will definitely love the following frameless furniture because they love to build houses with whatever they have on hand. Take the idea of the English designer Philippe Malouin into service; you can make such a product yourself.

For it you will need:

- thick fabric;

- corrugated cardboard;

- Velcro;

- stationery knife;

- long ruler;

- pen or pencil;

- scissors;

- thick foam rubber.

The base of this transformable chair consists of two cushions. How to make these from thick foam rubber was described at the beginning of the article.

- Two soft blocks are sewn together on one side so that they can be bent and placed one on top of the other.

- On the top block you need to sew a handle from the same fabric. When you want to turn the chair into a bed, simply pull it towards you.

- The back and side are made from several rectangles of corrugated cardboard. A piece of fabric 1 meter wide 50, fold in half lengthwise. Sew along the bottom of the large edge, and also sew one small side on the side.

- Place the first rectangle of cardboard there. Topstitch this fabric or stitch here on the arms to separate this first section.

- Now insert the second rectangle, make a vertical stitch on a typewriter or on your hands in the same way. If you want a transformable chair so that it turns into a tent, then you need to make not one, but 2 rows of cardboard rectangles.

- When it comes time to create a roof for a small house, you will need to raise the second side row and connect it at the top with Velcro. It is pre-sewn onto fabric blanks.

This is the kind of frameless furniture you will have if you want to create it.

To make this process even clearer, watch the video description from a specially selected story. It tells how to sew a pear chair, but not an ordinary one, but in the shape of a penguin. You will learn how to make a children's frameless sofa-chair from foam rubber in the second review.

DIY frameless sofa.

Upholstered furniture relaxes, encourages relaxation, and adds a touch of comfort and warmth to the interior. Sofas without a frame are one of the current trends in the furniture industry, consisting of several pillows. Such sofas will appeal to those who like rearranging; moving the light components of the sofa will not be difficult. The cost of such furniture is from 5 to 8 thousand rubles. However, making a frameless sofa yourself will not be difficult.

We present instructions for making a frameless sofa (prefabricated).

The sofa will consist of three reclining chairs. To make one chair you will need durable furniture fabric - 3 meters, width 150 cm, foam rubber 10 by 100 by 200 cm - 2 sheets. 5 sheets are consumed for three chairs. It is not recommended to replace thin sheets with one 20-centimeter block - such filler will quickly be crushed. With use, the foam rubber in the front area of the seats often sags. In this case, the pillows can be turned in the other direction or, by unzipping the zipper, place thin foam inserts. Zippers 80 cm long – 7 pcs. strong reinforced threads, PVA glue, centimeter, ruler, chalk, scissors, sewing machine.

The entire sofa is made entirely of folding chairs that easily transform into beds

Each chair will be made from 4 blanks. Each of which is made up of two pieces of foam rubber. We cut the foam rubber blanks into squares 80 by 80 cm - 2 pieces, rectangle 60 by 80 cm - 2 pieces, rectangle 20 by 80 cm - 2 pieces, rectangle 30 by 80 cm - 2 pieces.

Using PVA glue, two sheets of each workpiece are glued together. You should get four pieces, 20 cm thick.

Cutting and sewing the components of a frameless sofa.

Mark on the fabric and cut out two squares 80 by 80 cm (the back and face of the pillow). Don't forget to add a few centimeters for allowances. Then we cut out three strips of fabric measuring 20 by 160 cm.

First part diagram

Parts 1.3, fold in half and sew 2 zippers, towards each other. The result is a blank 20 by 160 cm. Now sew the blanks indicated in the diagram as a and b.

Sew stripes and squares on the wrong side, in a box-shaped pillow shape, with zippers in the middle. Finish the inner seams with an overlocker.

Frameless furniture is modern, simple and convenient; in Russia it is only gaining popularity; due to its peculiarity, it is very suitable for an active or even measured lifestyle. At first, the only example of frameless furniture was a bag chair, the name of which was given because of its shape, the disadvantages of such bags are that their filler, polystyrene foam balls, shrink (deform) over time, you have to buy the filler separately and constantly refill it. Over time, beds and poufs made of elastic rubber filled with water began to appear, which made them not only heavy but also inconvenient for operation and maintenance, later they began to produce inflatable furniture-mattresses, after the use of which there were identified disadvantages, a small margin of safety and the air evaporated over time or appeared punctures did not lead to anything good and became a thing of the past.

We went further, our workshop is engaged in the development, production and sale of frameless chairs based on furniture foam rubber (PPU), which makes the chairs hypoallergenic for the family, since many people have upholstered furniture, mattresses, soft toys and much more in their apartments, the filling of which is foam rubber. Some of our models are made of sheet solid foam rubber, which gives the chair good anatomical properties and keeps its shape for the entire service life, other models of chairs are made of crushed crushed foam rubber, which makes them soft and cozy, taking the shape of your body - the disadvantages of such models are that over time the foam rubber shrinks, but this is not the worst thing about everything because it can be easily brought into shape by simply whipping it or shaking it with your hands and it will come back into shape. Foam rubber in combination with durable fabric provides a large margin of safety for a long service life.

Frameless furniture does not contain a frame of rigid wooden or iron inserts; you can always easily rearrange your home or change your place to relax in your apartment or summer cottage.

Advantages - an interesting and useful addition to the interior through the variety and color range of armchairs from the Furniture Lamb

comfortable for all guests and family members to relax, the filler does not deform but shrinks and takes its shape again. Convenient for the body and muscle groups as it takes the shape of the body and makes it possible to relax muscles and relieve stress, easy to clean, you can vacuum it, clean it with a soft brush for clothes or wipe it with a damp sponge as the fabric is water-repellent.

There are a large number of models of chairs in the world: frame and frameless chairs!

Metal

A metal frame is a good choice. It facilitates intensive use, withstands heavy loads, and is relatively lightweight. It is important that the profile meets certain parameters: wall thickness from 3 mm, diameter not less than 35 mm.

The structure is made of high-alloy steel, aluminum, titanium alloys. To protect against corrosion, all elements are chrome plated or varnished.

The metal frame breaks extremely rarely, and if damaged, repairing it is not so difficult.

The elements are connected by welding or using bolts.

The first option is considered more durable and will cost the buyer a little less. Bolted fixation of parts will allow you to easily remove and replace the damaged area, but it requires regular inspection and tightening of loose fasteners.

Advantages of a metal frame:

- acceptable price;

- long service life (up to 30 years);

- smaller dimensions of the final product;

- safety;

- high load resistance.

Before purchasing, testing is carried out to identify possible defects.

The structure must stand firmly on supports and not sway at the slightest touch. Shakiness and creaking indicate poor fixation of bolted connections. In the case of welded products, it is recommended to visually assess the quality of the seams. They must be smooth, even, and free of tears and sharp edges. Damage to the protective coating and the presence of pockets of corrosion are considered unacceptable.