Structure of vinyl tiles Main types of tiled linoleum Advantages and disadvantages of tiled linoleum Laying tiled linoleum Preparatory process and installation

Linoleum tiles are known to many, but some have worked with modern building materials, while others have installed a version from the last century in their homes. In the article we will consider the version called vinyl tiles, since it is this version that is popular today for its aesthetics, quality, reliability and durability.

Vinyl tile structure

As mentioned earlier, tile facing material has long been created on the basis of polymers and was used to cover floors. That modification was not of the best quality, and the flooring deformed very quickly given intensive use.

The reason for such negative products is that tile linoleum was previously made in the form of single-layer squares or rectangles. The basis for the material was standard polyvinyl chloride (PVC). Essentially, linoleum tiles were plastic sheets that could not withstand heavy loads.

Modern material is more durable due to its updated structure:

- The product is based on a polyvinyl chloride sheet (vinyl), the thickness of which is no more than 0.5 millimeters. This layer is used to increase adhesion to the base and elasticity;

- followed by softer PVC with a reinforced layer of fiberglass;

- Next is a 2-3 mm flexible vinyl base interspersed with fine quartz sand. It is necessary to stabilize the product and ensure its basic performance properties;

- Decorative paper with a certain pattern or texture is glued on top of the base, making the tile visually beautiful, both in the photo and upon close inspection;

- linoleum in the form of tiles, coated with a layer of polyurethane with various additives, has the highest quality and cost. This coating protects the material from wear, abrasion, fading in the sun, etc. In some cases, polyurethane has a special additive that eliminates the sliding effect.

This combination of linoleum and tiles in one product has significant advantages over other coatings:

- multi-layering allows the coating to withstand the standard load created by residents;

- the materials used in production ensure resistance to the chemical effects of various chemicals;

- The multilayer structure is also excellent in operation due to high depreciation rates, not much different from those inherent in rolled linoleum.

We combine different materials

Many people separate tile and linoleum because they are tired of dirt and dust. Most often, the place where the two materials meet is the kitchen. Linoleum and tiles allow you to highlight functional areas - dining and cooking areas.

Tiles are usually laid on the dining area, and linoleum on the hob. It is much more pleasant to move on it, since it is much softer and does not slide as much. The line dividing these two coatings is too large, therefore, to make a high-quality and safe transition, overlays are used. Also, tiles are laid in the corridor, because most of the dirt from the entrance gets there. Due to the fact that the joint line between the rooms is shorter, the two canvases can be joined with profiles.

The main types of tile linoleum

Previously, the construction market could only offer customers commercial linoleum for tiles, but today you can refuse imitations and buy individual tiles directly.

The following types of such products are known:

- By molding, tiles are distinguished into standard geometric shapes: square, rectangle, triangle, and the hexagon is especially valued by designers, since it can be used to create the most original coatings;

- according to the characteristics of the surface of the tiles: glossy and matte effect, non-standard texture for linoleum and anti-slip effect (abrasive treatment).

Important! It is not recommended to use abrasive coatings in residential areas, as they lead to damage to socks, slippers, etc. It is best to use them in public places, where more durable shoes will not be at risk.

Unlike simply applying a pattern to rolled linoleum, tiles are produced using several technologies, which also determine its classification into several types:

- quartz-vinyl

- 80% consists of quartz ground into sand. High strength and density of products is determined by pressing under high temperature. Quartz itself makes the material resistant to abrasion; - pressed

- created from vinyl, resins, plasticizers and hardeners. The mechanical resistance of this variety is lower than that described above, but higher than that of ordinary linoleum; - self-adhesive panel

– have high elasticity, allowing it to be used as a finishing material for floors, walls, furniture, etc. Structurally, this material is not much different from rolled linoleum.

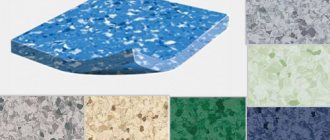

Choosing a design for such tiles will not be difficult, since almost any wishes of the buyer can be satisfied. Among the tiled materials, not only tiled linoleum stands out, but also more elite types: palace tiles or tiles with a texture that imitates natural wood. There is no limit to the imagination of designers who have even created tiles that imitate crocodile skin.

Is it possible to lay tiles on linoleum

This unusual idea arises from people who have no experience in carrying out repairs. This idea is prompted by simple laziness. The owners do not at all want to dismantle the old coating before laying the new finish. This is due to labor costs and a lot of garbage, which is difficult to dispose of from the apartment. This will end with the inventors of the new technology ending up with a finish that is not what they dreamed of. It will take twice as much money and labor to correct errors.

Laying tiles over linoleum is not a good idea.

Repair specialists do not use this technology, and some of them have not even heard of such an innovation. To figure out whether you can lay tiles on linoleum or not, it’s worth reading how homeowners argue for such an idea:

- The linoleum is pressed down by heavy furniture. To dismantle it, you don’t want to disassemble it and take it out. The argument goes beyond all boundaries of fantasy. Firstly, how to glue the tiles then. No one applies the finishing coat to the furniture. Cover the entire floor. Secondly, the furniture is not timeless. What then to do with the spots without tiles when you rearrange or install new furniture of a different size? Finishing materials are released with new designs every year. After a few years, it is difficult to select exactly the same tile to cover a stain.

- Linoleum has been firmly established over the years and is difficult to dismantle. The argument is extremely false. Most often, linoleum is laid dry without glue. It is pressed only by the baseboards against the wall. In a couple of hours they can be easily removed and the old coating can be rolled up. Even if the linoleum is glued, over the years the adhesive composition has partially deteriorated. The canvas will easily come off the subfloor.

The linoleum released from under the baseboard can be easily removed from the subfloor - Without dismantling the linoleum there will be less waste. The argument is stupid only because the person does not know the technology for carrying out the work. If you really want to, you can lay PVC tiles on linoleum, but only if you have a rigid base. That is, a concrete screed is poured over the old coating with reinforcing mesh laid. After this work there is so much dirt that it will take more than one day to shovel it out.

Advice! If you are extremely reluctant to remove the old coating, it is better to lay new linoleum or carpet on top.

If you ignore every problem, thinking your arguments are correct, other problems may arise over time. For example, you decided to sell your home. An experienced buyer will see that the floor finishing technology is broken. The owner will have to make concessions on price.

Advantages and disadvantages of tiled linoleum

Naturally, such a coating has both positive and negative sides.

Positive characteristics include:

- modern linoleum with a tile pattern or any other texture has high strength, many times greater than that of rolled linoleum;

- the multi-layer structure makes the material flexible and elastic, facilitating installation and increasing comfort during use;

- the polyurethane layer protects the tiles from moisture and sunlight;

- small proportions of one tile simplify the installation process, since it is easier to join tiles than to lay a long roll perfectly evenly;

- Finally, fire resistance makes the material even safer. And even during combustion, a minimal amount of harmful toxic substances is released.

Vinyl linoleum for ceramic tiles and other types of coatings also has disadvantages:

- the material is susceptible to the formation of dents due to prolonged exposure to heavy objects on its surface;

- the cheapest products have a low-quality polyurethane layer that poorly protects the decorative layer from fading;

- the cost of the material is similar to laminate, so you shouldn’t try to save your budget when choosing this flooring.

Linoleum

Also a popular material for kitchen flooring. When people talk about linoleum, they most often mean the synthetic version because of its many advantages.

The most important advantages of linoleum are cost and ease of installation. Even families with middle and low incomes can afford linoleum, and they don’t have to spend money on a laying specialist—you can do it yourself.

Linoleum comes in three types:

- commercial;

- semi-commercial;

- domestic.

As the name implies, you should give preference to the latter option. It comes in three classes: 21, 22, 23. The class affects how quickly the coating will wear off and under what loads. Since the kitchen is a trafficked place, you should choose class 22 or 23 linoleum with a thickness of 3–5 mm.

The main advantages of this coating are:

- resistance to damage (but not falling knives) and abrasion - will last about 15 years;

- water resistance and ease of cleaning;

- ease of installation and replacement;

- wide design.

You should not associate modern linoleum with its Soviet counterparts. Now there are such specimens that cannot be distinguished from laminate or tiles. There is also embossed linoleum with a slight structure - this will enhance traction and prevent slipping even on a wet floor.

Laying tile linoleum

If, for example, you bought white linoleum for tiles or any other, then you can install it yourself. The worker will need the following tools: measuring devices and a marker for marking, a square made of wood or metal, a spatula and grater for the adhesive mixture, a sharp cutter for cutting the material and a rubber roller.

It is advisable to use a cutting tool in which the blade is replaceable, since abrasive coatings will lead to its rapid frenzy. You will also need an adhesive mixture to lay the material.

Linoleum under tiles in the interior

The decorative solution of linoleum imitating tiles is most popular in the kitchen interior, although with the right approach it can be used in living rooms and hallways. This floor looks organically in a variety of styles, emphasizing the nobility of retro trends or enhancing the dynamism of modernity.

Linoleum under tiles in the interior looks very elegant, emphasizing the style of the room

Light colors easily allow you to create a harmonious image of a kitchen or living room, since they optimally combine with the surrounding environment, visually expanding the space. For a status and majestic classic, you can choose a pattern with the texture of wood or stone. Dark tile-like linoleum floors are recommended for spacious rooms, where they create an atmosphere of comfort and elegance.

Preparatory process and installation

As with any floor covering, you will first need to create a perfectly flat base without defects in the form of cracks, chips, depressions and bulges. In case of significant distortions, it is worth pouring a screed (cement-sand or using a ready-made self-leveling mixture) or laying a plywood sheet with a thickness of 0.8 centimeters as a base.

The material should be adapted before installation by bringing it into the room where the work will be carried out in advance. This will reduce deformation during installation and further operation of the coating. Next, marking is done using prepared tools. The most important thing is to make the areas of the floor that will be visible to those entering the room and stand out in the photo if the installation quality is poor. The option of pre-laying tiles without gluing is considered reliable, since you can check how correctly the markings have been made and see what the floor will look like upon completion of the work.

As for installation, the easiest way is to use self-adhesive semi-commercial linoleum under the tiles, because It is enough to simply lay it on the base by first peeling off the protective film from the bottom. But this option, as mentioned above, is not reliable and high-quality, so we will next consider the process of laying more durable varieties of vinyl tiles.

How to properly prepare the base for laying linoleum on different substrates

- Seal cracks, eliminate irregularities and bumps, vacuum the entire area where the linoleum is laid.

- If there is already linoleum on the floor and there are no holes, bumps, waves, or unevenness on it, you can leave it and lay a new one on top of the old one. Old linoleum needs to be cleaned of dirt and washed. If the condition of the old linoleum is unsatisfactory, it must be removed.

- Laying linoleum on a wooden floor is a rather complicated option. It is advisable to cover the floor of old boards with chipboard or plywood, and smooth out the joints with putty. If the floor is rotten, it must be removed. If linoleum is laid on a wooden floor base, it must be sanded and primed.

- Laying linoleum on a concrete floor is not particularly difficult if it is level. An uneven concrete floor is leveled using a screed. The solution for it is prepared from sifted river sand and cement - 1 part cement to 3 parts sand. You can also use a ready-made self-leveling mixture. To prevent cracks from appearing on the screed, it is moistened for five days: water the floor with clean water, but not more than three times a day.

- In the case of old coverings with ceramic tiles or PVC tiles, before laying linoleum, they are thoroughly cleaned, cracked ones are removed, and the voids are filled with cement mortar. If the damage is minor, the tiles are glued together with epoxy resin, dried, and then sanded.

Self-adhesive floor tiles: composition and artistic solutions

Regular tiles are laid out in the following sequence:

- an adhesive mixture is prepared (acrylic dispersion);

- a layer of substance of 1.5-3 millimeters is applied to the tile with an approximate consumption of 0.3-0.4 kilograms per square meter. Before using the mixture, it should be left to steep for 5-10 minutes;

- gluing vinyl tiles should begin from the corner of the room opposite the front door with a distance of 0.5-1 centimeter from the wall in case the tiles expand under the influence of high temperatures;

- additional leveling is done using a rubber roller or cork board. When processing the coating, it is important not to move the tiles from their intended locations;

- seams between adjacent products must be sealed with cold welding if there is high air humidity in the room.

In those places where the tiles meet other coverings, decorative metal thresholds are installed. This element will protect the joining floorings from deformation and prevent the seam from clogging. Also, under the coverings, various insects and bacteria will not find a new place to live.

Bottom line

The idea of replacing standard roll material with vinyl tiles is a very good one. The advantages of such coating are undeniable and therefore the high cost is quite natural. Since its installation is quite simple, you won’t have to spend money on help from builders. If all the work in the house is carried out exclusively by hired workers, then they can be entrusted with responsibility for all stages - from the choice of coating, naturally, taking into account the wishes of the owner, to the finishing processing of the created cladding.

Composition of vinyl self-adhesive tiles

Composition of self-adhesive tiles

First of all, it should be noted that the self-adhesive vinyl tiles on the market are a multilayer coating, each layer of which is responsible for certain qualities of the material:

3D floor tiles: choice, advantages and disadvantages

- A surface layer of polyurethane or transparent vinyl film about 0.5 mm thick is responsible for the wear resistance of the material;

- The main vinyl layer with an applied pattern and texture creates the necessary decorative properties;

- Fiberglass mesh prevents mechanical damage and stabilizes geometric dimensions when outside temperature changes;

- PVC backing made of foamed polymer improves the sound and heat insulation properties of the finished coating;

- An insulating layer that prevents the penetration of dust and moisture from the surface of the subfloor and onto which a layer of adhesive is directly applied, with unique adhesion to various durable coatings.

In some tile samples, manufacturers add crumbs of natural minerals to the base layer of the material, which not only increases wear resistance, but also gives an original appearance, and specialized processing of the top protective layer significantly reduces its photosensitivity, which increases the durability of the coating and allows the use of self-adhesive tiles outdoors.

Technologies for laying modular (tiled) linoleum.

Storage and transportation 1. Storage of floor coverings • When storing in a warehouse, maintain the appropriate internal room temperature from 1C to 30C. • Do not expose to direct sunlight or moisture. Store tiles away from snow and rain. 2.Transportation The material is heavy, care should be taken when transporting the tiles.

Installation Floors must be clean, smooth, dry, level and structurally sound. • Remove existing floor covering. New flooring must not be laid over old flooring. • Dry the base (humidity less than 5%). Never lay floor tiles on a wet surface. • Clean the base. Remove traces of stains, dust, paint, fats and oils, bitumen, varnish, wax, glue and other contaminants. The substrate should not contain materials that could prevent good adhesion. Do not use cleaning mixtures, solvents, lemon adhesive removers, or acid etching to clean the substrate. • All cracks, recesses, holes must be leveled. Use self-leveling compounds. 2. Precautions It is strongly recommended to keep the flooring in a horizontal position and the adhesive at a temperature of 20C to 30C for at least 48 hours before and after installation. ATTENTION: Before installation, it is necessary to check the quality, color and pattern of the coating. Try to use material from the same batch. The batch name contains information about the color and batch number, as well as the production date.

Types of linoleum

Now let's talk about what types of linoleum exist.

Linoleum can be divided into household, semi-commercial and commercial. Each of these varieties has its own qualities . Let's take a closer look at each of these types of linoleum.

Return to content

Domestic

This linoleum is designed for use at home , that is, in apartments and private houses. Such premises are characterized by low load and low traffic. As a rule, such linoleum is quite thin, from 1.2 to 1.6 millimeters , but according to experts, this thickness is absolutely sufficient for home use. The cost of such linoleum is not high , and the average service life is approximately 5-7 years , with careful use.

Return to content

Semi-commercial

This type of linoleum differs from household linoleum in that it is more resistant to wear and is suitable for rooms with an average level of load . This linoleum has certain similarities with commercial linoleum, but at the same time it costs less .

Semi-commercial linoleum for tiles has a special layer of protection that makes it more reliable .

The basis of semi-commercial linoleum is PVC, which distinguishes it from commercial linoleum. such a coating is reinforced with a fiberglass mesh , due to which it is possible to achieve higher sound and thermal insulation characteristics.

Purchasing this type of linoleum is not difficult, since it is sold in any hardware store . The cost of semi-commercial linoleum can vary, depending on the composition and the company that produces it. Compared to tiles, semi-commercial linoleum will cost less , which makes it very popular for use in both apartments and offices.

Return to content

Commercial

Now let's look at the highest quality and most durable type of linoleum - commercial linoleum with a tile pattern. This type of linoleum appeared on the market relatively recently. As is easy to understand from the name, this linoleum is designed for use in commercial premises that are exposed to heavy loads during the day.

The cost of commercial linoleum is slightly higher than that of semi-commercial and household ones , but at the same time it can withstand heavier loads and is also not sensitive to chemicals.

Commercial linoleum may vary in its composition and manufacturing technology. There are artificial and natural commercial linoleum.

In the manufacture of unnatural linoleum, as you might guess, materials of synthetic origin are used . In the production of natural linoleum, materials such as flax oil, wood flour and various fibers of natural origin . Due to the use of such materials, with proper care, such linoleum can be successfully used for 30-40 years .

Return to content

How to lay tiled linoleum - features of the material

Similar lot numbers indicate similar product types. 3.Where to start laying floor tiles • Find the center of one wall of the main rectangle, and from this point draw a line to the opposite wall. Then find the center of the other wall of the rectangle and draw a line to the opposite wall. The center of the main rectangle for the cover will be the point of intersection of these lines. • For a test installation, lay a row of tiles from the center to the side wall. This will help you determine the distance from the end tile to the wall. If the distance between the edge of the last tile and the wall is more than 1/2 tile, mark new center lines 1/2 full tile away from the previous center. • When tiling a room with a different shape, check the size of the last tile on each wall and then change the center lines slightly to help you achieve the best results. 4. Applying Adhesive • Start with 1/4 of the area of the room. Apply the adhesive evenly using a flat V-notch spatula, leaving no seals of adhesive. The optimal glue consumption is 0.3-0.4 kg per sq.m. • Check the crystallization time of the glue. This period of time is calculated from the moment a layer of adhesive is applied to the coating until it completely dries, i.e. when other objects are not glued to the coating. Determining the crystallization time of the glue allows you to make subsequent gluing stronger. It depends on the climate, porosity of the base, etc. More detailed information can be obtained from the technical specifications of the adhesive manufacturers. If the crystallization time is too long, the maximum bonding strength will be lost. • Each floor covering must be installed using a special adhesive and trowel. ATTENTION: In case of unfavorable moisture and temperature conditions of the room, use two-component polyurethane glue. 5. Laying tiles Tiles should be laid from the center of the room to its corners. Place the tiles according to the positions of the arrows on the back side. Lay the tiles without displacement. Before pressing it firmly to the floor, adjust it to the edges of the already laid tiles.

6. Laying tile pieces • To lay tile pieces, lay the tile to be trimmed exactly on top of the last full tile; Place another full-length tile against the wall and mark a cut line where the tiles overlap. • Cut the tiles along the line. Before laying, check that the cut tiles fit well. Do not force it into place. • Lay the tiles and press them into place. ATTENTION: For laying against a wall, it is necessary to roughly cut off the excess tiles in accordance with the contour of the wall, leaving a 1mm margin. 7. Completion of work • Roll a roller weighing 10-30 kg lengthwise and crosswise over each section of tiles for 30 minutes after laying the section of tiles. If in some places it is impossible to roll with this roller, use a hand roller. Perform a visual inspection during the rolling process to ensure that the tiles have not moved and that there is no adhesive on the surface of the tiles. Check each laid section after rolling to check for any raised edges. Roll the roller lengthwise and crosswise a second time for about 30 minutes. If necessary, roll again. • Sweep the floor. • Remove debris and construction materials. • The floor can be washed 48 hours after installation. Stains can be removed with a damp cloth. • It is recommended to install furniture and other items on new flooring no earlier than 48 hours after installation. When installing furniture, it is recommended to use cardboard and dollies. • When working with heavy objects, use cushions to avoid damaging the coating. Necessary tools and materials • For installation: metal scraper, chalk for marking, measuring tape, rubber (wooden) hammer, square, art knife, rag or sponge, spatula with grooves for applying glue, heavy tamping shaft, glue, flooring coating. • For care: mop (for cleaning the floor, with a sponge or cloth), sweeping brush, wax mastic, detergent.

At the moment, the industry offers a very large number of materials for flooring: parquet, laminate, tiles and many others.

But the most economical is linoleum. It is quite easy to care for, durable, and inexpensive. For a very long time, these qualities were the main ones when choosing this material. Today, linoleum tiles are becoming more and more popular.

Linoleum for tiles is, first of all, a very convenient material. It has proven itself to be easy to use for any design option. The ability of such a pattern to visually expand the room is highly valued. Very often the question arises before renovation: to lay linoleum under the tiles or just tiles.

Laying PVC tiles on linoleum: step-by-step instructions

When the linoleum is hidden under a reliable layer of screed, you can begin laying the slabs. The surface is checked again for horizontalness. If there are differences or holes, it is better to eliminate them. Otherwise, there will be a large consumption of glue, which is extremely unprofitable.

Set of tools

You can’t lay PVC tiles on linoleum with just anything. You will need to prepare a special set of tools:

- container for preparing the adhesive composition;

- notched spatula;

- rubber spatula;

- cutting device - tile cutter;

- level, tape measure, pencil;

- plastic crosses.

You should have a dry rag and a bucket of water on hand in case you have to wipe off glue-stained slabs.

To work, you need a tool that helps you mark, cut, and install

How to glue PVC tiles onto linoleum

To glue the boards, you need to select an adhesive composition. It is important to calculate the approximate amount you will need. Retail outlets offer a large selection of glue from different manufacturers. Experienced builders recommend using the following brands:

- KIILTO 2PLUS is produced by a domestic company. The adhesive composition is made on an acrylic base. Does not contain aggressive solvents. Suitable for gluing any PVC materials, including quartz-vinyl tiles. Approximate consumption – from 200 to 300 g/m2.

A 1.4 kg can of glue is enough for approximately 5-7 m2 of floor areaImportant! The adhesive is suitable for use in damp rooms and can withstand heating up to 50 °C in a “warm floor” system.

- Homakoll is considered a universal adhesive. Made in Russia. Suitable for gluing PVC boards and other finishing materials onto absorbent and non-absorbable substrates. It is made on a water-dispersion basis and does not contain aggressive solvents. Withstands heating from the "warm floor" system. Approximate consumption – from 300 to 350 g/m2.

The adhesive allows the slabs to be moved during open operation - Thomsit is similarly a domestically produced product.

Designed for gluing all types of PVC finishes to any substrate. Retains stickiness for a long time after application to the parts to be glued. Approximate consumption – from 200 to 300 g/m2. The glue can be applied with a spatula and a foam roller - Arlok 38 is considered one of the inexpensive domestic adhesives. Water is used as a diluent. Withstands 5 freeze-thaw cycles. Approximate consumption – from 230 to 450 g/m2.

The consistency of the glue is of medium viscosity; a spatula or roller is used for application.

Each type of glue is used according to the instructions. The manufacturer displays it on the packaging. You cannot deviate from the recommendations of the instructions, as this will affect the adhesion strength of the slabs.

Why is linoleum so popular?

Linoleum has long lived up to all expectations placed on it. That is why it is the most common material for covering kitchen floors.

This is due to its durability and not being picky. And factors such as spilled water or anything else (which is very common in kitchen areas) do not affect the coating in any way, unlike, for example, laminate, which can swell due to moisture.

The advantages of this material are ease of selection for a specific design (the assortment is very large), ease of care (just wash, you can use various chemicals, except caustic ones), non-slip thanks to a special coating, good resistance to mechanical stress, and, of course, such the floor is much warmer than tiles.

If we consider flooring options for the kitchen, then you should pay attention to wear resistance, ease of maintenance, and reliability.

What do we do before purchasing?

If you still decide to buy linoleum, then first of all you need to think about the purpose, find out everything about the manufacturer (country and company), how long it can last and the presence of all the required certificates (hygienic, quality compliance), storage conditions and subsequent packaging can also be quite a lot important.

Before purchasing, you should also pay attention to the division of linoleum into household, commercial and semi-commercial.

Domestic

Household linoleum is intended for use at home. That is, in rooms with low traffic and load.

Usually it is quite thin (1.2 - 1.6 mm), but it is believed that this is quite enough for using such material at home. Of course, such linoleum is inexpensive, but its service life is very short - about 5 - 7 years.

Article on the topic - features of reinforced household linoleum. We recommend reading.

Important: the floor on which such linoleum is laid must be level.

Semi-commercial

Semi-commercial linoleum is a floor covering with high wear resistance for rooms with medium load. It has properties very similar to commercial ones.

The protective coating layer has a thickness of 0.5 mm; the coating is made of wear-resistant material.

PVC is the basis of commercial linoleum, this is the main difference between commercial and semi-commercial linoleum. Often, this flooring material can be reinforced with fiberglass mesh, which provides thermal and sound insulation.

Purchasing this material will not be difficult for you, since it is available in any store that deals with flooring. Its cost may vary, it all depends on the composition and, of course, on the manufacturer. But still, buying linoleum for tiles will cost you less than laying the tiles themselves. You will be pleased with the relatively low cost of the material.

Coating structure

Foamed linoleum base is a source of harmful toxins

Linoleum can be divided into two types:

- Heterogeneous . Consists of several layers.

- Homogeneous . It has a uniform structure throughout its entire thickness.

In heterogeneous linoleums, felt or a foam layer is used as a base-substrate. And with the latter, serious problems very often arise.

The foam layer of the coating contains harmful chemicals. Not only do they cause unpleasant odors for several years, but they also cause headaches and nausea. Therefore, if you put such linoleum in an apartment, then in rooms with minimal traffic. But under no circumstances in bedrooms or children's rooms.

Homogeneous linoleum is produced from a homogeneous mixture, which includes PVC, plasticizers, polyurethane, stone chips, lime and chalk. The cost of such linoleum depends on the composition of the homogeneous layer.

Cheap linoleum uses more chalk, lime and sand, which makes the coating loose and unpleasantly rough. The composition of more expensive linoleum mostly includes synthetic components: polyurethane, PVC and plasticizers. This coating has a denser structure and a smooth surface.

Single-layer linoleum is used, as a rule, in rooms with high traffic. This coating is not hazardous to health, but the cost per square meter can reach up to 2–3 thousand rubles.

Quartz-vinyl tiles are multilayer. Moreover, not a single layer contains harmful substances

Quartz vinyl is a safe and environmentally friendly material. No toxic oils or adhesives are used in its production. Therefore, even when heated, quartz-vinyl tiles are chemically neutral. It can be safely used not only in living rooms of an apartment, but also in kindergartens and schools.

Linoleum tiles: selection and installation technology of vinyl covering

Commercial

Installation process

And now a little about what commercial linoleum is. It appeared on the market relatively recently. Designed for use in commercial premises, that is, in premises where a lot of people pass through during the day.

Regarding the price: it will cost a little more, but is more durable and not sensitive to chemicals.

Linoleum may differ in its composition. It is divided into natural and artificial, homogeneous and heterogeneous.

Natural consists of linseed oil, wood and cork flour, resins and natural pigments, and the base is natural fibers. Thanks to this, it can serve you for 30 to 40 years.

The production technology of this floor covering has remained almost unchanged over time; manufacturers have just learned to depict various beautiful patterns on the covering, including tile patterns.

Kitchen floors always require additional coating. Using linoleum is a very convenient and justified option. Its cost is relatively low, and its quality is not inferior to other floor coverings.

Another advantage of linoleum is that many types have an antibacterial effect, and retain it throughout its service life. And some have antifungal treatment, but this property of the coating weakens significantly over time.

Joining at different heights

Well-known seam design options include a multi-level joint. The difficulty of its execution lies in the fact that it is difficult to find high-quality fasteners, and without it, if physical stress is applied to the lining, then over time it will become loose and can be easily pulled out with one hand.

To avoid this, you need to choose the right threshold with a vertical difference between linoleum and tiles of no more than 1.6 cm. In this situation, you will need to purchase a special step with two supports, which can be placed on both surfaces without any problems. Such models are mainly mounted on polyurethane foam.

About market leaders

One of the most famous manufacturers today is the Belgian company Beauflor. It specializes in the production of high-quality, natural linoleum.

It is natural linoleum that is distinguished by its wear resistance. Therefore, if you choose linoleum for tiles, you should pay attention to this manufacturer.

Linoleum has an additional top layer, which makes it low maintenance, less likely to need polishing, more durable and economical. And the increased density of the base improves resistance to severe damage.

Of course, there are different types of linoleum, and when you decide that you will lay this particular floor covering, you will be faced with the question: “Which tile should be imitated?”

Let's look at a few types:

- The most traditional pattern is for ceramic tiles. This pattern came into fashion back in the last century and still remains relevant. Of course, it is not entirely suitable for modern designs, but it is still in demand.

- Imitation of block parquet and wide parquet boards. Very often not only beech, oak, cherry are reproduced, but also more exotic species such as bamboo, rosewood and others.

- Decor imitating mosaics on wood (marquetry technique) is in great demand today.

- For lovers of extraordinary things, manufacturers can offer a wide variety of colors, geometric or abstract designs.

- Stone-like linoleum looks very nice.

- As an option, you can consider narrow rectangular planks.

Tarkett linoleums are developed using the latest and most modern technologies, taking into account the latest trends in the world of design.

This manufacturer produces only environmentally friendly material that meets all standards and hygienic standards. That is why it is very often used in hospitals, kindergartens, and schools. Linoleum from Tarkett has a high degree of sound and heat insulation, which frees you from unnecessary financial waste and increases the level of comfort.

We hope that this article will help you choose the right linoleum. Happy renovation!

Advantages of linoleum for tiles

Of course, linoleum compares favorably with cost tiles , and the difference is quite significant. Linoleum has a shorter service life, but high-quality varieties of this material can successfully maintain their attractive appearance for many years.

Other advantages of this coating include ease of installation. Simpler installation technology can significantly reduce the time required to complete such work.

A large assortment of different linoleums allows you to choose exactly the pattern that best suits the interior of the room. When choosing linoleum for tiles, it is worth noting that it can visually expand the room , which is important for owners of small apartments.

You should not assume that linoleum is some kind of low-grade material. Over the past decades, production technology has made significant progress , due to which more expensive varieties of linoleum have really good quality indicators.

Unlike tiles, the surface of linoleum is much warmer and, when used with a good backing, allows you to keep the room warm even in the harshest weather conditions.

Speaking about the advantages of linoleum, one cannot fail to mention how simple and easy to maintain this material is. Linoleum is not afraid of moisture , so it is completely washable using cleaning agents.

Return to content

Advantages and disadvantages

Snow-white flooring has the following advantages:

- Visual increase in area;

- Light colors of the coating give the interior nobility;

- Acts as an additional light source, reflecting sunlight and artificial light;

- Plain milky material gives the room spaciousness, lightness and airiness;

- The white board color material will be an excellent backdrop for bright and unusual accessories.

There are no ideal floor coverings; they have not only advantages, but also disadvantages. They need to be studied during interior planning.

The material also has the following disadvantages:

- If there is an excess of light tone in a room, it looks cold and empty;

- On the sunny side the material may turn yellow;

- Any traces, debris, dust are clearly visible.

Keep in mind that when laying white linoleum on the floor, all debris will be visible, as well as traces of tea, coffee or felt-tip pens.

However, light-colored flooring material has more positive aspects than negative ones. The main thing is to choose the right pattern and texture.

Design for white linoleum

White linoleum in the interior goes well with furniture and appliances in the interior. The light color of the floor will harmonize perfectly with the black doors that are popular today. A floor of this color visually increases the area of the room, which is very important for those who have a small apartment.

To the kitchen

A white floor in the kitchen will create a feeling of cleanliness and comfort, and if the room is small, it will also visually increase the area of the room. You can choose white linoleum for the kitchen under the laminate; it will be practical, cheap, and practically indistinguishable in appearance.

Of course, all the dirt will be visible on such a floor, and you will have to clean it quite often. In addition, a pure white kitchen can create the appearance of a hospital.

Designers recommend choosing not a purely light floor for the kitchen, but one with the addition of other shades, patterns or colors. For example, linoleum with black and white tiles will look good.

To the hallway

The hallway is a high-traffic area, so it is recommended to install thicker household flooring material. If the room is narrow and dark, then it can be visually expanded with a light floor. Although it will need to be washed frequently.

A stone-like canvas will look elegant.

Types of self-adhesive linoleum

An example of using tile linoleum in the kitchen

Vinyl flooring is presented on the market mainly in the form of square tiles measuring 45x45cm or strips similar to laminate, but measuring 91x15cm.

Frost-resistant linoleum. Scope of application and customer reviews

Self-adhesive linoleum tiles are presented on the market in the form of two collections from the Tarkett company, the price of which ranges from 500 to 700 rubles per sq. m. m. Six decor options for the New Age collection and eight textures for the Lounge collection allow you to choose the best option for decorating any interior. The products of the Belgian brand Vinilam are somewhat more expensive, the quartz and vinyl tiles of which have a pronounced structure and are slightly thicker.

Similar material is also offered by another Belgian company IVC under the Stepper brand, whose products are of consistently high quality. The Korean company Rose Rosa does not lag behind European manufacturers, offering high-quality products in the mid-price category on the market.

Self-adhesive linoleum for laminate is presented in thirty-two decorative options that imitate natural materials. Precious wood species and skillful imitation of stone fit harmoniously into any stylistic and design solutions.

The optimal dimensions of the elements allow the use of self-adhesive linoleum when laying it both along the walls and diagonally in the room with a minimum amount of waste. Varying different decor options in one room allows you to visually zone the space, which will be especially appreciated by owners of small apartments.

Tarkett antistatic linoleum: characteristics and types of material

Laying self-adhesive linoleum is simple, but requires some care. It is almost impossible to tear off a glued tile from the base without damaging the adhesive layer.

Linoleum with a tile pattern

In this case, it is not necessary to buy expensive natural material, but give preference to linoleum.

As an interesting design solution, you can lay linoleum in black and white squares in the hallway.

Living room

The living room is designed in soothing colors that set the mood for relaxation and a comfortable pastime. To give the interior an expensive look, you can lay linoleum in the color of white marble. This coating will look good in an interior where there are plaster statues, a fireplace or massive furniture.

White glossy linoleum will look interesting in the living room. This material will perfectly suit the style, which will make the room beautiful and unusual.

Children's

The children's room should be light, so it is advisable to use light shades for flooring. You can find material options that combine white color with an original pattern, produced specifically for children's rooms.

Bedroom

When choosing the color of linoleum for a bedroom, many designers advise choosing light, pastel or milky tones. In this color the room looks unusual, but for the bedroom it will be very useful.

Regardless of whether the style is classic or modern, light colors will look good in it. It will add tenderness and softness to the classic style. White color in a modern style is a sign of minimalism, as all attention is focused on the surface, making the entire interior less noticeable.

Photo gallery (6 pcs.)

From the photographs you can understand what white linoleum looks like in the interior:

Most often it is made in the style of wood and boards, less often it is a monotonous coating.

We offer a comparison with how embossed wood-look linoleum in light and dark shades will look.

Design

Linoleum for tiles can have completely different patterns and designs , as well as imitate different types of tiles.

Let's highlight the most popular types of linoleum design for tiles.

- The most popular design is linoleum for ceramic tiles . This type of pattern gained consumer demand back in the last century and continues to be actively used to this day.

- In addition, quite often you can find linoleum that imitates parquet boards .

- Linoleum, with imitation mosaics on wood, is becoming quite popular

These are not all types of linoleum design solutions, but only the most popular ones , so you can choose exactly the option that best suits your personal preferences and taste .

Caring for white linoleum

One of the advantages of white linoleum is that it is easy to clean. To prevent dust from flying around, it is better to vacuum the floor rather than sweep it. Following simple rules for caring for the coating will help not only extend its service life, but also preserve its appearance:

- Do not use hot water for cleaning;

- Bright sunlight will cause the coating to fade;

- Do not dry or ventilate in winter to prevent cracking;

- Do not use abrasive cleaning products when cleaning;

- Do not use detergents containing chlorine;

- When cleaning wet, wring out the cloth well.

It is not recommended to clean the white oak patterned flooring with bleaching agents, otherwise the pattern will be destroyed.

Traces from furniture are clearly visible on a light-colored canvas; this can be avoided by placing wooden plates under the legs. It is advisable to use special care products for coating.

Snow-white Tarquette flooring can be used for various rooms, be it a spacious living room or a small bedroom.

By choosing the right tone and texture, you can get an extraordinary and beautiful floor that you won’t want to hide under a lot of furniture.

Properties of linoleum

Commercial linoleum is a convenient and economical thing. It is laid quite easily, and if installed correctly it can last up to 25 years. There are two types of commercial linoleum - homogeneous and heterogeneous coating.

Homogeneous coating is a durable and elastic linoleum, uniform throughout its thickness. Its pattern penetrates through the entire homogeneous layer of linoleum. Even with severe wear and surface damage, its appearance does not change. That is why homogeneous coating is ideal in corridors and other places where the floor is heavily used.

Due to the characteristics of a homogeneous coating, its pattern does not differ in diversity. It can be a single-color canvas, abstract patterns “marbled”, “granite-like”. This pattern is perfect for offices. But the monotony of appearance is compensated by the advantages:

- wear resistance

- durability

- antistatic

- ease of maintenance.

- the appearance of the coating can be restored.

Homogeneous coating is in demand in places where there is possible severe mechanical damage to the floor, as well as in offices and rooms with computer and high-tech equipment, which are harmful to static electricity.

The top layer of homogeneous linoleum is PVC. Since polyvinyl chloride is a fairly expensive material, talc or lime can be added to the raw material to reduce the cost of production.

If, when you bend a sheet of homogeneous coating in half, a white stripe appears, it means there is too much limestone in its composition. Mixing with surface dirt, limestone forms whitish stains that cannot be destroyed with regular wet cleaning of the room. This coating must be sanded periodically.

Heterogeneous linoleum is based on fiberglass coated with a polyurethane coating. The method of manufacturing heterogeneous flooring allows us to achieve a huge variety of colors and patterns. Its varieties:

- sound absorption

- antistatic

- anti-slip - the production technology of heterogeneous linoleum makes it possible to make its surface textured and covered with pimples. Metal chips are added to the mixture.

- conductive

- depreciation.

Multilayer coating is in demand in rooms with high humidity, as well as where increased sound or heat insulation is required.

Having chosen which coating will be most suitable for the room, you should decide whether to lay the linoleum yourself or invite specialists. The question arises - how much does it cost to lay linoleum?

The price of laying commercial linoleum varies from 110 RUR/m2 to infinity. The cost of the material itself starts from 400 rubles per meter. You must pay separately for welding seams. At the same time, the cost of the work also includes preparation of the surface for the finishing coating.