Share on social media networks:

Installing gas lifts on furniture is a process that anyone who starts making furniture with their own hands will encounter in any case. It is advisable to install such lifts so that you do not have to frequently repair this or that product. This simple device can be installed on any furniture without the help of specialists. This way you will ensure reliable fastening of the doors, their silent and smooth opening and closing with one movement of the hand. The most important thing here is to choose the right gas lift, which will save you from many problems and create the most comfortable conditions in the kitchen. Today we will talk about the device itself, consider its strengths and weaknesses, and present to your attention installation instructions with a list of basic recommendations.

Design features and advantages of gas lift

Any mechanism consists of several parts, and a gas elevator is no exception. So, what parts does this device include:

- The body is in the form of a sealed cylinder.

- Sleeve.

- Valve.

- Bypass valve.

- Piston.

- Anther.

- Stuffing box.

- Bearing.

- Piston seal.

- A rod that moves inside the housing.

- An oil seal packing that creates a tight seal for the device.

- The working medium is in the form of nitrogen, which is pumped inside the housing.

pros

Gas elevators have many advantages, but we will highlight the most basic:

- Possibility of self-regulation of the stroke.

- Reliable fixation of the drawer in the open position.

- There are two ways to open the gas lift - step-by-step and automatic.

- Possibility of selection according to the material from which the furniture is made for installing the load-bearing element (aluminum or chipboard).

- The door can be opened without a handle; it is enough to open it slightly for the mechanism to work.

Main selection criteria

To choose the right gas elevator, you will need to determine:

- type of system;

- technical specifications;

- manufacturer.

Types of gas lifts. Their advantages and disadvantages

To assemble furniture we use:

- direct action lift;

- reverse action lift.

A direct-acting gas elevator operates on compression. This is the most popular version of the lifting system, as it is simple to manufacture, lower cost and easy to install.

Direct acting gas lifts

Reverse-action furniture lifts, on the contrary, work to extend the rod. Fittings are more complex to manufacture, as high precision is required during production, which primarily affects the cost of the equipment.

Reverse action furniture lifts

Gas elevators can also vary in how they open. There are models:

- with a step-by-step design, that is, manual opening. The cabinet door or other folding element in this situation is equipped with a handle that facilitates the process of controlling the lifting mechanism;

- with automatic design. In this case, the lift is equipped with an electric drive that drives the lifting mechanism.

Electric furniture lift

Determination of technical parameters

In order for a pneumatic gas elevator to serve for a long time, you will need to determine:

- compression force;

- equipment dimensions.

When calculating independently, the compression force of the spring is determined taking into account:

- weight of the folding structure (facade, bed, rising part of the chair, etc.);

- the distance determined from the center of the axis of operation of the equipment to the middle of the lever (center of gravity);

- height between the center of the system axis and the equipment mounting location;

- number of installed lifting mechanisms.

Data and calculation method for gas lift for furniture

Installation Rules

Before installing a gas lift in a cabinet, it will not hurt you to understand the following points:

- It is better to install two gas lifts on one front, so that when it opens, there will not be a lot of tension that can warp it.

- Gas elevators with a force of 100 Newton are practically not installed due to the fact that they require very massive and large doors, which are not often found. It is not advisable to use such elevators due to the increased liquid level.

- The front with the lifting mechanism is adjusted by hinges that secure it to the box.

- Before assembling the box, in which the fittings are subsequently mounted, it is necessary to install fasteners.

- You can increase the door opening angle by moving the mounting point closer to the front part of the sidewall.

- When installing automatic elements, you must strictly follow the installation instructions.

Installation technology

How to install a gas lift system on a cabinet? Before installation you must:

- determine the method of fastening the fittings;

- prepare tools to do the job;

- familiarize yourself with the diagram for attaching the lift to the cabinet door.

Mounting methods

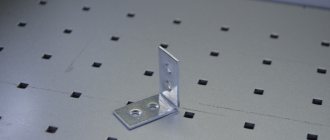

The gas lift can be installed on a furniture cabinet:

- using fixing pads secured with self-tapping screws. This option is easy to install, but can only be used for products made of wood, chipboard, MDF and analogues;

- using screws with a locking function. The primary area of use is metal and plastic surfaces.

Tools and materials

To perform installation work you will need to prepare the following kit:

- tape measure, square, marker (pencil) for applying preliminary markings;

- drill for preparing holes for fastenings;

- screwdriver and screwdriver for fixing the lift.

A gas lift is exclusively an additional device that facilitates the process of using a cabinet or other piece of furniture. The main fittings of a cabinet door are furniture hinges.

Even after installing the gas lift, the main load is taken by the hinges

Gas lift installation

Direct installation is carried out after installing all the cabinet door fittings according to the following scheme:

- determination of mounting locations for furniture lifts. The location of fasteners is determined in accordance with the planned opening angle of the cabinet door. As a rule, installation dimensions for all situations are indicated in the attached instructions;

Determining lift mounting locations

- in the marked places holes are drilled, the diameter matching the size of the fastening bolts;

- fasteners are fixed;

- The gas lift is fixed on the fasteners. Fixation is considered complete only after a click. In some situations, fixation requires some effort.

Gas lift mounting

You can watch the video for more information about the process of installing the lift yourself.

It is recommended to carry out work on installing a gas elevator before the final installation (hanging) of the cabinet. This will allow you to apply markings more accurately and avoid distortions. It should be remembered that in order to ensure the correct operation of the fittings, it is recommended to install two lifts on cabinets, beds and sofas.

Researchers estimate that the world's population spends almost 3 trillion hours in the kitchen every year. Maybe that’s why people strive to equip the kitchen as much as possible, turning it into a cozy island for cooking, drinking tea, and having heart-to-heart conversations.

The most important thing in this is to correctly select and install kitchen units and various appliances and mechanisms, for example, gas lifts on cabinets. This is not an easy task, but it is quite doable, you just need to be patient and useful tips. We will tell you what a gas lift is, what it is needed for and how to choose it, as well as the features of installing it on a kitchen cabinet.

How to install a gas lift on a cabinet door?

The installation process of gas lifts consists of several stages, which we will now consider.

Required tools:

- Screwdriver.

- Electric drill.

- Pliers.

- Screwdriver.

- Hammer.

- Roulette.

- Ruler.

Markup:

- We check the suitability of the selected gas lift. So, for a wall cabinet with an internal cavity height of 365 mm, a gas element with a length of 355 mm is needed.

- We mark the furniture. First, mark the center of the fastening on the sidewall. We measure the height L2 from the inner upper area of the lid, equal to 366, and from the front part of the sidewall - 37 mm. Mark the center of the fasteners on the cabinet door. We measure the length L1 from the top edge of the door, equal to 128 mm, and from the side we measure a distance equal to the entire height of the fastening on the side of the furniture - 19 mm. We carry out such markings on both sides of the wall cabinet.

Installing a gas shock absorber on furniture:

- We mount fasteners on the side parts of the structure, having previously outlined the required distance. For this, two fastening options are used - brackets with a spring and a plate.

- According to the above instructions, we install fasteners on the facades so that the angle of inclination of the hinge is approximately 8 degrees.

- Now let's assemble the box.

- We install the facades on the frame, securing the canopies at the top level.

- We install elevators. A click will tell you that they are attached to the head.

- We close the front part and adjust it using hinges.

Important! The brackets are screwed into the material of the side of the cabinet at the marked point, and the volumetric head of the mechanism is simply fixed in the bracket. If the mount has a plate type with a hole, then it is fastened with three or four screws to the end so that the center of the recess coincides with the previously marked point. The most important thing is that the plate should not be deformed, otherwise the elevators simply will not work.

How to assemble a kitchen gas lift?

This structure is completely sealed. Nitrogen penetrates the cylinder during production, but if the element is damaged, it will simply be impossible to restore it. Proper installation of the device in a cabinet under the sink should begin with the preparation of tools that may be needed in the work. You should also draw the contours in advance to ensure the most accurate installation.

When choosing wall closers for kitchen cabinets, you need to take into account two indicators that are of particular importance: the parameters of the device and the spring compression force.

It is important that the kitchen device matches the size of the cabinets well. To do this, you need to take measurements, find out the height of the doors, as well as the depth of the furniture with drawers.

As a rule, you need to choose between several standard sizes. In addition, you need to check several parameters of the gas lift: folded length with and without fasteners, as well as the length of the retractable rod.

In order for the installation of the upper devices to go as smoothly as possible, you need to pay attention to the compression force. This parameter is standardized and must be included in the mechanism’s passport.

When choosing equipment, one cannot fail to take into account the system through which installation is carried out. Most often in practice, flat platforms are used, which make it possible to install them on the side surfaces of kitchen cabinets through the use of screws. If the furniture has a wooden body, then it is better to use screw-in fasteners. When working, you will need tools such as: screwdriver, pliers, screwdriver, hammer, electric drill, ruler.

The assembly of the cabinet under the sink itself occurs in several stages:

- Marking wall cabinets in the kitchen. Watching the video will help you understand how to do this job correctly. First, the middle fastening points on the side surface are marked. Then the middle of the fastening on the sash is marked. The marking is done on both sides of hanging furniture or floor cabinets under the washbasin.

- Installation work. The base is attached to the side element in the place where the marks were placed. Here you can use two simple methods known to professional assemblers. The first involves using a bracket with a spring, and the second - a plate. Typically, the bracket is screwed into the side piece where the mark is made, with the elevator head snapping into the bracket. The second option involves using a plate with a hole made in it. It is fixed with 3-4 screws to the side, and in such a way that the middle of the recess coincides with the mark. The gas lift head is inserted into the recess and secured in it. It is necessary to ensure that the plate has no visible flaws, since if deformed, the finished device will not work as it should.

- Perform the actions described in the previous paragraph when working with the inner surface. A hinge angle of approximately 80 should be ensured.

How to adjust the gas lift fasteners in a kitchen set?

In the open position, the facade can have three positions - 90, 70 and 100 degrees (elevation angle) relative to the side of the furniture. So, it may be difficult for a short person to reach the door to close it, or someone needs to look under the door to get the necessary things. To do this, you need to adjust the gas mechanism. Here's a visual guide:

- We change the markings of fasteners on the front part of the product.

- Mark down to the center of the fastener 100 mm. This is done so that the front end has a 70 degree position when open. To obtain the position of the gas lift at an angle of 90 degrees, we mark 90 mm according to the same scheme, for 110 degrees - 80 mm.

- The permissible error when adjusting the gas mechanism is 5-10 degrees.

Important! The tilt angle can be adjusted more precisely. To do this, you need to turn the internal thread, which is located in the gas lift cylinder, in order to raise or lower the facade.

Load selection

Lifting mechanisms have specific markings - 50, 60, 70, 80, 100 and 120. These parameters characterize the level of pressure in the cylinder and show the force with which they are able to lift the doors. It is not recommended to install strong devices on lightweight facades.

Typically cabinets have a standard height of 720 mm. For a facade with a top opening option, this height is equal to half, i.e. 360 mm. The weight of the door changes with the height of the cabinet; according to this, a gas lift mechanism with a certain load parameter is selected:

- up to 65 cm – 50;

- up to 80 cm – 60 or 70;

- up to 100 cm – 80 or 100, three pieces each.

The use of gas lift systems with high loads (80 or more) requires strengthening the fastening of the upper horizon to which the loops cling.

Knowing these installation features, when installing gas lifts there is no need to drill extra holes.

Video material

We really hope that you will no longer have the question of how to attach a gas lift to a kitchen cabinet with your own hands, because now you know all the nuances of installing this mechanism.