What is bog oak

Bog oak is obtained through the process of long-term soaking of wood in a liquid with mineral salts, as a result of which the wood acquires new properties and original color. This process is called mineralization, which takes place in the natural environment. The extraction of such wood is carried out in places where oak groves grew thousands of years ago - often these are swamps. Changes in river beds carried them under water, where the trunks and branches remained intact and acquired incredible strength.

Under the influence of chemicals, the shade of the wood changed - it became darker and more saturated. And the outer layer usually consists of black plates of coal, although the oak was not in fire, but, on the contrary, under water for many centuries.

Application area

Previously, it was often used for interior decoration of palaces and castles.

Nowadays, this type of oak is used for the manufacture of furniture and interior decoration elements (parquet, wall slabs, mosaics).

Souvenirs and jewelry made from this raw material are also exclusive and very interesting. However, finding them is quite difficult, because the manufacture of such products is carried out by a narrow circle of specialists.

Benefits of use

Strength, durability, unique and unusual shade - these are not all the advantages of wood.

The distinctive properties of the material also include:

- Protection from parasites. This wood never harbors parasites. This may be due to the natural chemical treatment that the wood received as a result of the natural staining process.

- Spirituality. There are opinions that oak has unique powerful energy accumulated over thousands of years in unique natural conditions.

- Uniqueness. This natural product has no analogues in terms of aesthetic, religious, cultural and historical parameters. The exclusivity of the products is also due to the fact that there are no two identical trunks in the world.

This high-quality natural product has been valued and in demand at all times, but, unfortunately, oak supplies are limited and cannot be replenished. Although there were attempts at the beginning of the last century.

Areas of use

Furniture oak panels, having all the advantages of natural wood, are free from its inherent disadvantages. Correctly selected material will optimally fit into both classic and modern interior design solutions. Oak canvas is used:

- in the production of furniture - cabinets, walls, cabinets, bedrooms, beds, kitchen sets, children's;

- stairs, doors, window sills, railings, which are subject to increased loads and must withstand changes in temperature and humidity;

- for interior decoration of premises - verandas, cafes, hotels;

- in the manufacture of exterior items - benches, benches, gazebos;

- for the production of decorative elements - shelves, frames, carvings.

Purpose and types of furniture hinges, installation nuances

Closet

Bed

Tabletop

Ladder

Windowsill

Interior decoration

Table with benches

Shelf

Bog oak in the interior

This wood, despite its rarity, is used quite often in a variety of fields. The rarity and value of the material requires fine manual processing.

The most popular area of application is interior.

This wood is used to make:

- pieces of furniture;

- souvenirs;

- floor finishing materials;

- wall coverings;

- stairs;

- window;

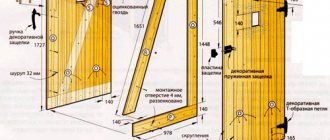

- doors.

Interior items made from this type of wood are characterized by a long service life, and decorative elements are doomed to turn into antique objects.

This material will be an appropriate solution when creating a room design in a Scandinavian style. Furniture made from this wood in the interior is a sign of the prosperity and excellent taste of the owner of the house.

Furniture

Due to its high cost, furniture made of bog oak belongs to the elite category. The high cost is due not only to the limited natural reserves, but also to the complexity of extracting and processing wood - only a fairly experienced craftsman can handle work of this nature. The quality and originality of the product, as a rule, is documented by the seller.

Tables are the most popular category of oak furniture. Made of oak, it is perfect for a kitchen interior in Baroque or classicism style.

In the living room, an interesting solution would be a coffee table. You can put a small table for tea ceremonies in the dining room, and a table for accessories and cosmetics in the bathroom.

In commercial and administrative premises, tables made from this noble raw material are almost universally used. They become a bright and noticeable detail in the director's office or in the conference room.

Advantages and disadvantages

Furniture made from this natural product has a number of advantages:

- attractive and solid appearance;

- environmental friendliness and safety;

- strength and durability;

- a wide variety of options;

- the ability to assemble and disassemble furniture several times.

Products made from this material are truly reliable and strong.

However, they also have a number of disadvantages:

- high price;

- the products are quite heavy;

- difficulty of handling in case of damage.

Experts advise trusting the work of professionals in the manufacture and assembly of furniture, since without some experience it will be quite problematic to “tame” the wood. The talented work of the master will turn tables and other furniture into works of art. Wood that is resistant to any external influences predicts a long life for products made from it. They can serve their owners for many decades, or even hundreds, passing from generation to generation.

Nature-treated oak is a reliable material for creating wood windows with rich texture, excellent thermal and sound insulation, strength and durability. Do not forget that this natural material does not require additional care and is perfectly protected from aggressive environmental influences. In addition, such windows will look organic in almost any interior.

Useful properties of oak and its characteristics

Oak is a material with an ideal chemical composition. It contains many healthy micro- and macroelements, phytoncides, which are released into the air and have an invisibly beneficial effect on the human body. Due to its composition and beneficial properties, oak is used as firewood in bathhouses and fireplaces. If you put them in the oven or fryer, you get an amazingly tasty meal.

As for performance qualities, oak is characterized by the following:

- high hardness and strength;

- moisture resistance;

- resistance to rotting, fungi;

- heavy weight;

- high density;

- excellent for gluing when assembling structures from several elements;

- slight resinity.

If you decide to buy oak furniture, you definitely won’t regret it; it will please you for a long time. And to choose a really beautiful and high-quality set or individual interior items, choose and purchase them from the Ecofurniture Bio company.

Staining oak at home

Modern technologies make it possible to imitate the color of wood. Scientists have achieved that they can recreate the color while maintaining the aesthetics and moisture resistance of the material. The option of making it at home is accessible and simple. Ultimately, you can get a unique oak material with silver veins inside.

In order to obtain such material, you need a special mixture that imitates the shade of natural moraine wood - stain.

The product is applied in two steps: the first layer must be applied to the surface of the wood at a slight angle, applying strokes across the grain, the second - along. To work, you should use a flute - a flat, wide brush specially designed for applying stain and creating natural, imperceptible transitional shades of tone. The soft and resilient bristles of the brush make this tool the best of its kind. Most often, stain is used to treat laminate flooring.

Composition of stain

The composition of the product is simple. Wood impregnation is divided into types based on the base material.

The most popular include:

- Water. The most extensive and popular group of impregnations. It is produced in finished form or in powder form. The advantages include: non-toxicity, wide range of shades, ease of application, low consumption, affordable price. Disadvantages: the ability to lift wood fibers, opening access to moisture, long drying process. If during the work, due to impregnation, the wood fibers are damaged and the hairs of the fibers stand up, then you should wait for complete drying and treat the surface with sandpaper, and then cover it again with a layer of impregnation. Excessive wetting can be prevented by coating the dry surface with varnish.

- Alcohol. Like water, it is sold dry or ready-made. Dries quickly. On the one hand, this property saves time, on the other hand, to get a uniform tone, experts recommend using a spray gun. When applied manually, alcohol impregnation often creates greasy stains. To work with this stain, you must have protective tools: special gloves and a mask. Otherwise, there is a chance of getting a chemical burn or poisoning.

- Oily. Pigments dissolved in oil allow you to tint a wooden surface in all possible shades. At home, this product is quite convenient: oil stain fits perfectly on the surface, does not require special tools for application, penetrates evenly inside without disturbing the texture of the wood, and forms a protective film.

- Acrylic and wax. Stain made from these substances is a new generation of materials for processing and protecting wooden surfaces. The main advantages of the material are considered to be: the formation of an insulating film, a wider range of colors in comparison with other impregnations (from natural shades to exotic ones). The effect of a bright colored coating based on natural wood structure is called stain. Modern designers quite often use stain to transform interior elements. The main disadvantage of the material is its high cost.

- Alkyd. This product helps to obtain wood in the natural desired shade, increases the resistance of the material to external negative factors acting on the material. The product after such impregnation does not require varnishing, only for shine.

The eye of a professional will, of course, always distinguish between raw materials made at home and natural ones. Based on this, artificial material is often used in rooms with high humidity: baths, saunas, swimming pools to make it less noticeable.

Benefits of oak wood

Oak wood is a high-quality building material. It is simply impossible to list the list of applications where oak wood is used. It starts from land-based buildings and underwater wooden ships, ending with key chains, cutlery, Chinese chopsticks, vases and other decorative items.

For home use, oak is used to make material for stairs, doors, parquet, cabinets, sofas, kitchen walls and other various household utensils. After all, real strong wood does not rot, repels dust, does not absorb odors, and its service life is at least 10 years.

Oak wood is an excellent building material

The advantage of oak is its pronounced cross-sectional pattern and a wide range of shades, which look very good on home furniture. In addition, oak material is easy to change and process. Thanks to this, in skillful hands you can achieve incredible texture and design.

The natural shades of oak amaze with their diversity and beauty: from pure white to black and charcoal. At the same time, there are no red shades in the range of colors. There are only gold, gray, beige, brown. And these are exactly the colors that will look perfect in your bedroom or kitchen.

Where is oak wood used?

Finishing materials, in particular oak parquet boards, are in demand in the construction industry. Carpentry companies use oak wood to produce a whole range of products: edged and solid boards, slabs. The products do not lose their attractiveness over time and withstand severe climatic and operational tests. The material is in demand for the construction of various buildings - edged boards serve as a frame for wooden houses; its use is also justified for interior decoration.

Bog oak

Bog oak is a completely unique mineral resource. It is so unique that it is sometimes equated to gas or oil. Bog oak is an incredibly beautiful and high-quality material that was created by nature itself, absolutely without human intervention. It is the natural origin of this material that makes it so rare and in demand.

Bog oak is mined in the deep waters of rivers and swamps. Thousands of years ago, oak groves grew on the banks of these rivers, but over time, the waters washed away the banks and the trees fell into the water, remaining in the bowels of the earth and below the water level for several hundred, or even thousands of years.

Without access to oxygen, tannins contained in wood react with iron salts found in water. Due to the lack of oxygen, wood does not rot. When interacting with iron salts and other elements of the periodic table, which our rivers are rich in, oak wood acquired unique physical and chemical properties.

Extraction of bog oak from rivers and swamps

For example: various shades - from light gray to coal black with a purple tint; The color depends on the time spent under water and the composition of the water. Also, stained oak becomes stronger and more durable.

Since the wood is located in different swamps and rivers, that is, it is in different conditions, each tree acquires a unique color and texture.

Which significantly increases its cost, because everyone wants to own some unique and rare item.

Some samples of bog oak were studied in the laboratory and subjected to radiocarbon analysis, which made it possible to determine the age of the oaks, which ranged from 400 to 2000 years.

The influence of natural conditions on the properties of wood

English oak grows on nutritious soils of the European part of Russia. This is one of the most durable species with positive performance properties, which has made it a valuable material used for house construction. The wood has a pronounced texture (a large number of heart-shaped rays) and a noble color - the core is brown with a green tint.

It is elastic, dense (690 kg/m3), strong, retains its quality when exposed to air, even after being underground or under water for a long time. When processed, it cracks moderately, chips easily, bends without effort, and is well impregnated with modern protective compounds. She is not afraid of fungus.

Bog oak, which has lain in water for a long time, has high decorative significance. Its wood is dark, almost black. After undergoing the etching procedure, the structure becomes voluminous and silky. This is a favorite material when decorating antique-style rooms. The panels are appropriate in living rooms made in a classic style.

Using bog oak

Bog oak wood has been used for quite a long time and mainly in the most luxurious interiors.

Initially, bog oak found its use in the Middle Ages, in Rus' and in many European countries. He was very highly regarded among the noble family. After all, chic furniture, interior items, royal thrones and even entire palaces were made from this wood, which, in turn, were passed down by inheritance. Today, similar objects made of bog oak can only be seen in museums.

Bog oak is a unique gift from nature

Bog oak is still used today, but deposits of this unique material are becoming fewer and fewer. After all, its popularity is growing every day.

Today, doors, parquet, furniture, souvenirs, billiard cues, etc. are made from bog oak. But we will not dare to talk about the cost of such products out loud.

Processing technologies

What characteristics oak wood will ultimately have is influenced by the processing technology used, because, for example, the properties of bog oak and bleached or other options will differ.

Despite the fact that today special chambers are widely used to speed up the drying process of wood, this technology is not recommended for use with oak. Due to the characteristics of the structure and density, hardness of oak, cracking may occur if moisture is lost too quickly. With traditional drying, this takes about 3 years.

Staining - using this technology, oak wood is given a decorative appearance. The principle of processing the material is that it is soaked in water for several years. As a result, the wood acquires an interesting rich purple hue, a silky texture, and its hardness increases.

Brushing is another oak processing technology in which some of the soft wood fibers are mechanically removed. As a result, the surface has a clearly defined structure of annual rings and pores; they are often painted in different colors.

Bog oak material in our interior

The highlight of bog oak is its special color: coal black with a purple tint. This combination is very difficult to achieve artificially.

Magnificent texture of bog oak

Although, according to experienced specialists, only a professional can distinguish a door made of ordinary wood (only painted) from a door made of bog oak. So be careful.

Bog oak wood has many valuable qualities, one of which is its flexibility to paint. The material can be easily tinted or varnished.

Stained color is a very stylish and original solution for the interior. Moreover, it is good both as parquet and as light elements in the kitchen. For example, the façade of a hood made of bog oak will give it elegance and sophistication.

When planning a renovation, do not forget that the stained color is quite gloomy and dark, so it should be used in spacious rooms with good lighting. Or in small rooms, but only with stained-colored elements. A combination with white and beige shades will look much more profitable and more expensive.