What it is

Cold welding of floor coverings is a chemical method of joining materials that does not involve the high temperatures associated with conventional welding.

The adhesive composition, entering into a polymerization reaction with the linoleum material, dissolves and melts the edges of the canvases. Their plastic deformation occurs. After completing the process of interaction of the mixture with the coating, a strong seam is formed at the joints of the sheets, and the structure is uniform in structure with the material being joined.

With a high-quality connection of the canvases, the joining seam is not noticeable.

The popularity of using adhesives for joining linoleum cloths of the “cold welding” type is due to the ease of working with them, the relative low cost and the versatility of the method.

Hot welding of linoleum

Hot welding is used to join the edges of rigid linoleum, which contains natural components. This method is used in high-traffic areas when it is necessary to reliably seal linoleum joints.

Pros and cons of hot welding

Hot welding has several advantages.

- This method is much more reliable than cold welding.

- The high melting point of the special cord used to seal joints makes it possible to make the seam airtight.

The disadvantage of this method is that it is not used for all types of linoleum, but for those whose components do not melt at high temperatures. These are mostly hard linoleums. The disadvantage of hot welding is also the need to use special expensive equipment, which not everyone can handle.

Tools for hot welding linoleum

To ensure welding of linoleum using high temperature, take the following tools for work:

- the quality of the seam will be lower than when working with a hot air gun.

- the need to use a hair dryer with a thermostat that will show what temperature it has heated up to. You can also use a soldering iron, but it does not have a thermostat.

- temperature control will help to weld the seam efficiently;

- nozzles;

- cord for hot welding of linoleum. It is made from the same material as the flooring sheets themselves. Under the influence of high temperature, the edges of the linoleum and the cord begin to melt. The cord falls into the joint between the edges, filling this space. The seam becomes invisible, and at the same time durable and reliable;

- arched knife or crescent-shaped scissors. the tools will help you quickly and accurately remove excess glue, unlike straight ones, which will not cope with this job.

Technology of hot welding of linoleum seams

The flooring sheets are not laid overlapping, but at the joint. First, the linoleum sheets are glued to the base, and only after drying should you begin to weld the joints of the panels. Gluing linoleum is a prerequisite for hot welding, otherwise the edges of the floor covering will bend. Next, using a special construction knife, make a groove 2-3 mm wide. This recess is made two-thirds of the thickness of the linoleum. This groove is necessary to place a cord in it, which, melting at high temperatures, fills the recess, firmly connecting the linoleum sheets together. This filler rod can be round or triangular in shape. The groove should be thoroughly cleaned of debris using a special vacuum cleaner. Install a special attachment on the hair dryer.

Thread the rod into a hot air gun . Turn on the tool and heat to a temperature of 350-400 degrees. The hair dryer has a spout that fits into a cut-out recess and releases the cord into it. The cord, passing through the hair dryer, heats up to a high temperature. The hot air causes the cord and edges of the linoleum to melt. The pressure roller presses on the molten parts, welding them tightly together. While the seam is still warm, you need to use an arcuate knife or special scissors to cut off the protruding parts of the cord and then sand it. The seam should be sanded using zero-grade sandpaper glued to a wooden block.

On a note! To make the seam invisible, you should lay the linoleum along the room or across it so that direct sunlight does not fall on it. When choosing an filler cord, make sure that its shade matches the color of the linoleum or is close to it in color. When using commercial and semi-commercial linoleum, hot welding allows you to firmly connect multi-colored sections of flooring panels, giving it a unique design pattern and an original color scheme.

Hot welding of linoleum using polymer tape

This method is performed using a special apparatus that looks like an iron. A polymer tape is applied to the joint of the linoleums. It protects the top layer of linoleum from burning. We use a hot welding machine, as builders jokingly call it, using an iron smoothly along the polymer tape along the entire joint. Under the influence of high temperature, the upper part of the edges of the flooring melts, connecting to each other. The tape is then removed. The connection is ready.

Compound

The typical chemical composition of reactive adhesives is simplistically a mixture of solvent and filler. The concentration of these two components determines the type and technology of work.

Solvent

The following can be used as a solvent in compounds for polyvinyl chloride coating:

- Tetrahydrofuran is a compound from the ether family. It can account for up to 80% of the total volume of the mixture.

- Acetone is a common ingredient in adhesive mixtures that have fast-setting properties.

Given the good solvent properties of acetone, it can be used to make glue at home.

Finely chopped pieces of old linoleum without a base are poured with this solvent and left for at least a day until a homogeneous consistency is obtained.

Glue made from solvent and linoleum residues

But it should be borne in mind that such glue will be significantly lower in quality than factory mixtures that contain special fillers.

Adhesive

Various additives serve as additives for adhesive fillers in mixtures intended for soldering linoleum:

- plasticizers;

- polyvinyl chloride;

- polyurethane;

- PSH-LS resins.

Pigments and modifiers can also be added to the adhesive mixture. Some manufacturers, for reasons of trade secrets, do not advertise information about component substances.

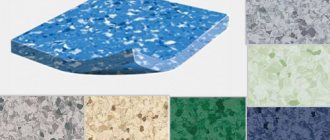

Types of cold welding for linoleum

There are three main types of compositions for non-thermal joining of linoleum - A, C and T. This classification was introduced by Werner Müller, a German manufacturer of cold welding systems for PVC coatings.

The letter designations to some extent reflect the shape of the nozzles.

Cold welding systems

The existing differences, mainly in the concentration of the mixture, determine the purposes for which they can be used, the types of work, as well as the material of the coating itself and its base.

The compounds are packaged in tubes equipped with various types of tips and nozzles, which allows you to place the mixture precisely into a narrow seam.

Cold welding adhesive type A

Type A compound is characterized by the following properties:

- instant readiness for use, the possibility of repeated use with good sealing of the packaging;

- consistency is more liquid than other types, due to the predominance of solvent in the mixture;

- deep and rapid penetration into the coating structure;

- high strength of connections;

- waterproofness and durability of the seam.

Feature - the tube is equipped with a built-in steel needle, which is closed with a special cap.

Type A glue

Type A glue

The technology for working with this glue is not complicated, but to obtain a high-quality result from soldering, it is necessary to properly prepare the joints. The needle should be inserted into the seam deeply, in doses and filling it evenly.

Adhesive type C

Mixture C has a thick paste-like consistency. Liquid PVC in it predominates over the solvent. This glue is usually used to repair existing coatings.

The set includes a narrow C-nozzle, which is used depending on the width of the seam (from 0.3 to 2 mm). To join wider (up to 4 mm) gaps, no nozzle is needed.

Type C nozzle

By carefully squeezing the paste out of the tube, which is held vertically or at a slight angle to the coating, the seam is uniformly filled with welding.

Type T

In terms of the method of preparing the seam, glue T is similar to type A. The joint of the sheets is done using the method of a tightly cut seam.

Feature - the function of a needle is performed by the included nozzle in the shape of the letter T.

Type of T-nozzle

Useful properties:

- alignment of protruding edges of canvases;

- low absorbency of the base with pile.

The soldering technology is similar to the welding method A.

Cold welding technology

For cold welding of linoleum, two types of glue are used - A and C.

The first type of glue has a liquid consistency because it contains a large proportion of solvent.

It is used when the seam width does not exceed 2 mm. If this value is larger, then the glue will spread and a reliable connection will not work.

The second type of glue is a thicker mass. If you are gluing freshly laid linoleum, it is more convenient to work with liquid glue.

Photo:

Scheme - cold welding technology for linoleum

Such sheets have perfectly smooth edges, because the linoleum is factory cut. The resulting seam has a minimum width and maximum strength.

When a wide gap has formed between the sheets, thick glue is used. This situation occurs when cutting the edges of linoleum at home in preparation for cold welding.

The glue fills the empty space and gradually hardens without losing its elasticity. The result is a strong and elastic seam.

The glue acquires its operational properties after two hours. After this period, you can walk on the linoleum without any fear.

A high-quality result is easy to obtain by correctly following the gluing instructions.

Seam formation

When cold welding two sheets of linoleum, it is very important to ensure that the seam is straight and neat.

At first glance, this task seems simple, but it requires proper preparation.

To do this you will need a sharp knife and a long ruler. Sheets of linoleum are laid on the floor in such a way as to ensure that one sheet overlaps the other.

The amount of overlap should be at least 5 cm. The next step is to draw a clear and straight cutting line with a pencil.

The material is cut along the marked line. The quality of the bond will be largely determined by the quality of the cut. It is very important to avoid deviations and zigzags when forming the seam.

Video:

Sometimes it happens that linoleum sheets move when cut. To prevent movement, the coating must be glued to the floor.

For these purposes, double-sided tape or glue is used. Cold welding is preferably performed on a glued coating.

Applying glue

When linoleum is laid in a residential area, it is advisable to perform this procedure in such a way that the number of seams is minimal.

When performing cold welding, you must remember that glue is an aggressive substance that comes into contact with the front side of the linoleum.

As a result of such contact, the appearance of the floor covering in the area next to the seam may be damaged.

To prevent this, the glue should be squeezed into the seam in a very thin stream. For this purpose, there is a special needle at the tip of the tube.

When performing cold welding of floor coverings, it is very important to achieve uniform distribution of the glue along the entire length of the seam. At this stage of the procedure, the performer must have a steady hand and a tenacious gaze.

Bonding linoleum can be done in two ways. In the first case, glue is poured into the seam between two canvases.

The second method differs in that first one sheet is glued to the floor, then another is docked to it in the same way and carefully leveled.

Video:

Criterias of choice

The efficiency of welding linoleum coating depends on the selection of the adhesive composition. All types of mixtures for non-thermal gluing of PVC have a transparent structure and do not disturb the color scheme in the seam area.

But it is necessary to take into account a number of conditions that determine the use of different types of adhesives.

The choice depends on the type of linoleum

Adhesive mixtures A and C are used with PVC coatings.

Class T cold soldering compound is used when connecting:

- polyester materials;

- heavy multi-layer commercial fabrics;

- linoleum on a duplicated basis.

This is a material based on felt (textile) and fiberglass.

Duplicated linoleum

Attention! Type A mixture is not suitable for soldering linoleum on a felt base.

Cover age

When working on cold soldering, it is necessary to take into account the properties of the coating:

- Compound A is used to join new linoleum;

- more viscous composition C - for repairing old coatings;

- T-class can be used to work with material of any age, but new installation is preferable.

Quality and shape of linoleum cutting

To achieve a good result in terms of strength and appearance of the seam when joining fabrics with compositions A and T, it is necessary that the joint be prepared with high quality, without cracks.

Preparation of the joint of the panels

The use of type C welding does not imply strict requirements for the quality of preparation of the panels for gluing. The predominance of polyvinyl chloride in this mixture allows:

- fill wide, up to 4 mm, seams;

- solder uneven edges of the canvas;

- join fabrics with complex cutting shapes, make appliqués.

Experience of the person who will perform the work

The simplest technology is considered to be joining linoleum sheets or repairing them using a more viscous composition of grade C.

With some skills, working with mixture “A” is not very difficult. An inexperienced repairman can also handle them.

But technical difficulties may arise with T-welding of multilayer semi-commercial and commercial coatings of a higher class. Therefore, repair specialists often work with this compound.

How to use cold welding

Construction adhesive, capable of reliably joining the floor covering, is a toxic substance, working with which is hazardous to health. Also, if used incorrectly, cold welding can corrode linoleum sheets, which will make the joint sloppy. You need to work with glue according to the instructions and following the following tips:

- When gluing sheets of flooring, you need to wear a special construction respirator and goggles to protect your eyes. Leave windows and doors in the room open. Ensure good air circulation.

- Select the composition of the adhesive carefully. Some types of joints and certain brands of linoleum require the use of welds with different percentages of glue and solvent.

- Do not leave the tube open for a long time, otherwise the glue will dry out. Putting a cap on the spout is not enough - it is better to insert a needle into it that fits the size of the hole or an awl.

- After gluing the seams, you should not try to speed up the drying process using hot welding or a simple hair dryer. This will reduce the volume of the adhesive and make the joint unreliable.

- While gluing, press the joints to the floor with an improvised press. This way you can avoid the appearance of air bubbles, which over time destroy the seam.

- After applying the adhesive, wipe the top of the flooring with a felt cloth to remove any excess PVC solvent. For the same purpose, masking tape is glued over the joints. Even with such protection, it is better to wipe the linoleum with felt.

Consumption: influencing factors and figures

Information about how many linear meters of joint a tube will be enough for is indicated by the manufacturer in the user instructions or on the packaging.

Consumption data on packaging

The amount of glue consumed for cold welding of linoleum is linked to a number of factors:

- Characteristics of the welding itself, declared by a specific manufacturer.

- Thickness of the material being joined.

- Master's qualifications (not always last).

After analyzing this information for mixtures of different brands, you can derive the average consumption rate by type of glue:

- A - 2.2 g per 1 linear. m;

- C - 3 g per 1 linear. m;

- T - 6.3 g per 1 linear. m.

It should be borne in mind that composition “C” shrinks up to 30% of the volume initially embedded in the seam. This feature makes it necessary to refill the joint with glue, sometimes several times, which increases its consumption.

Manufacturers and brands

The main manufacturers of cold welding adhesives can be judged by the rating of this product and the number of offers on the construction market.

Werner Muller

This is a world-famous German company founded by Werner Müller in Bindersheim.

Compounds for Werner Muller linoleum types A, C and T are represented by the Tarkett Rumix brand.

Brand Werner Muller Tarkett

Packaging - metal tube 50 ml.

Mixes for PVC material under this brand are distinguished by an excellent quality standard. When properly stored, they remain suitable for 3 years.

A short overview video about cold welding types from Werner Muller can be viewed below.

Cold welding Tarkett Werner Muller

Homakoll

Khomakol is a leading Russian company focused on the production of construction and industrial chemical products. Adhesive materials for household and professional use are one of its core areas.

The cold soldering adhesive from this company is represented by the S 401 brand.

Homakoll S 401

The mixture is suitable for joining all types of household and commercial PVC coatings and, according to consumer reviews, has many advantages:

- reliability of connections;

- preventing edges from beading;

- good waterproofing qualities of the seam;

- durability.

Packaging - 60 ml.

Master Teks

Adhesives and sealants produced by Mastertex (Poland, Russia) enjoy a large number of offers and good demand on the market.

Adhesive for cold soldering of linoleum and plastic is produced under the Master Teks Profmaster brand.

The basis of the adhesive composition is PVC resin.

Useful characteristics:

- the ability to glue complex figured seams and perform appliqué;

- high degree of adhesion;

- elasticity and transparency of the seam;

- moisture and heat resistance.

Master Teks glue

Package volume: 115 ml.

Helpful Tips for Cold Welding

To obtain a durable, high-quality and invisible seam using the non-thermal soldering method, there are several useful tips:

- carefully read the instructions for the adhesive and determine its suitability for working with a specific type of floor covering;

- with liquid compounds, the canvases are joined along an edge cut with the double-cut method - a double cut of overlapping canvases;

- the junction (edges of the canvases) and the base must be cleaned of debris and dust, degreased;

- to protect the edges of the canvas from melting, the seam is sealed with masking tape, followed by a cut in the center;

- the frequency of repeated filling of joints when the glue shrinks should be at least 2-3 hours;

- Before soldering, it is advisable to heat the seam area of hard coatings of semi-commercial and commercial classes with a hairdryer to a temperature of 40°C, but no more;

- To remove glue that accidentally gets on linoleum, you cannot use solvents - only soapy water, and as quickly as possible;

- When filling a seam with glue, you need to use two hands - guide the needle with the finger of one, and hold the tube with the other.

Technology for soldering linoleum

A prerequisite for using reactive adhesives is compliance with safety measures.

Work must be performed in a well-ventilated area, hands must be protected with gloves, eyes with goggles.

To summarize, we can say that cold soldering using high-quality modern compounds is a worthy alternative to other methods of joining linoleum, both in terms of quality and ease of execution.

How to glue linoleum using cold welding

Sooner or later, linoleum, which is most often installed in kitchens, loses its original appearance. The reason for this may simply be time, or heavy furniture being moved from one place to another, etc. One way or another, you have to change the linoleum, and after laying a new one, you are faced with the problem of how to remove the seams that formed when several strips meet. There are several ways to eliminate the resulting seam: hot and cold welding. It is quite difficult to do hot welding yourself at home; moreover, this technology requires a gas burner and you need to be very careful.

In view of this, cold welding is usually used to glue linoleum. This method allows you not only to do without unnecessary equipment, but also to glue complex seams, for example, with a turn. So, in this article we will talk about how to glue linoleum using cold welding.

Return to content

Cold welding technology

In fact, cold welding is nothing more than a special glue. It contains components such as tetrahydrofuran (80%), plasticizers and polyvinyl chlorides (20%). Those. The cold welding method is purely chemical. This adhesive is used for fast and technologically advanced jointing of floor coverings. The joint will not be visible at all if you strictly follow the welding technology.

Attention! While you are gluing linoleum using cold welding, be sure to open the windows, since the volatile solvents contained are harmful to health. It is recommended to wear rubber gloves on your hands and also prepare a face mask. Chlorine evaporates from the surface within 20 minutes and no longer poses a threat.

The glue is produced in tubes with a needle through which the adhesive composition is supplied. The needle allows you to completely fill the seam with glue. The chlorine contained in the composition dissolves the edges, making the seam even and smooth.

The following types of cold welding are distinguished:

- type A. Used on hard or new linoleum made of polyvinyl chloride. The glue is liquid and therefore allows you to eliminate even thin cracks. This glue “works” according to the following principle: a special composition melts the edges of the linoleum, thereby welding them. Therefore, with high precision of edge fitting, the gap becomes invisible.

- type C. The main use is for sealing the seams of old linoleum that have begun to separate. The glue differs in consistency from type “A” in that it is thicker; when applied, it fills the gap formed between the sheets and holds them tightly together. This glue can remove even large seams up to five millimeters. The relatively large width of the seam determines the possibility of a protrusion, which is subsequently cut off with a knife.

- type T. Used for linoleum made of polyvinyl chloride with a polyester-felt base. Used by professionals, it forms a transparent and elastic connection. It takes its name from the screw-on T-shaped attachment included in the kit.

Return to content

Tools

To glue linoleum using cold welding, we will need the following construction tools:

- knife;

- metal ruler;

- cold welding type A;

- masking (paper) tape;

- a piece of plywood;

- double sided tape;

- roller for more tightly attaching masking tape;

- gloves and face mask.

Return to content

Preparation of linoleum

Before you start gluing linoleum using cold welding, you should prepare the edges of the linoleum that will be welded together. In order for the seam to be invisible, it is necessary to ensure a tight fit of the edges of the linoleum to each other. To do this, we will make a simultaneous cut of two strips.

Attention! According to the cold welding method, in order to achieve an invisible seam, it is necessary that the linoleum be homogeneous without insulation.

The linoleum strips should be laid overlapping, with an overlap of several centimeters, and the edges of both strips should be cleaned from dust with a rag. To protect the linoleum from glue, apply masking tape to the bottom edge of the covering in the place where the double cut will be made. We lay the strips on top of each other and similarly glue masking tape to the edge of the top strip.

We align the strips of linoleum and cut them along a ruler or a suitable metal strip, cutting through both layers of linoleum at a time. Before cutting, place a piece of plywood under the joint so that the knife does not scratch the base and become dull. Next, remove the scraps from both strips.

If the linoleum does not subsequently stick to the floor with glue, then the seam area should be secured with double-sided tape and the edges of the linoleum should be glued to the base. Linoleum is most often fixed with glue in rooms with high traffic. Fastening the covering to the floor allows you to avoid deformation when moving furniture, cleaning, etc.

Finally, after smooth edges are obtained, the strips should be laid and pressed down so that there is no difference in height.

Another option for preparing the edges is to make a double cut, then apply paper tape so that the seam is located approximately in the center of the tape. Next, cut the tape with a utility knife (or a special knife with a round blade) along the joint line of the covering sheets.

It is possible to do without double cutting if the edges of the linoleum sheets are even. In this case, you just need to align the edges, stick the tape and cut along the joint.

So, we have prepared the edges.

Return to content

Cold welding application

Actually, now we have come to the final stage of cold welding linoleum, which is to apply glue between the strips. We press the needle into the slot and pass along the entire length, dosing the volume of incoming glue with the second hand. To obtain a high-quality seam, the cold welding solution should protrude about five millimeters onto the edges of the tape.

When carrying out work, it is important to avoid getting glue on the unprotected part of the linoleum. However, if this does happen, you should not immediately wipe the linoleum, as this may erase the coating pattern. Therefore, you should wait until the glue dries and clean it off with a knife.

After 5-10 minutes, the masking tape can be removed and the resulting tubercles can be cut off with a sharp knife blade. After a couple of hours, the glue will dry completely and become durable. The resulting seam has high strength and, when properly gluing linoleum by cold welding, does not visually stand out on the coating; the execution technology is simple and safe.

Return to content

Video

We present to your attention a video that clearly shows the entire process of cold welding linoleum.

Healthy? Save it to your wall! Thank you for like!

vse-postroim-sami.ru