Advantages and disadvantages of foam ceiling tiles

The advantages of this material are as follows:

- Since the temperature of radiators or radiators in apartments is no more than 80 degrees, such tiles can be safely installed in close proximity to them;

- Foam ceiling tiles can be glued to any surface;

- Under normal conditions, the service life of foam plastic tiles is calculated in decades, since this material is not afraid of dampness;

- The light weight of this material allows the use of adhesive compositions for gluing, which are not particularly durable and, accordingly, expensive;

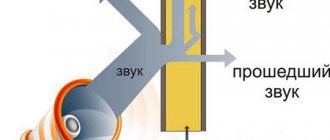

- Foam ceiling tiles are very dense, therefore they have excellent sound-proofing and heat-insulating properties;

- Polystyrene foam is an environmentally friendly material;

- Foam panels are very easy to cut, so their installation does not take a lot of time and effort;

Despite all the advantages, foam ceilings have many disadvantages. The cheapest foam tiles are not very durable; over time, they begin to turn yellow from sunlight, and some of them do not tolerate dampness well. However, this disadvantage can be easily corrected, turning it into an advantage, because foam tiles can be painted with ordinary water-based paint.

The most important disadvantage of foam ceilings is their vapor permeability - foam can create a thermos effect in the room, which prevents the walls from absorbing excess moisture. When combining foam plastic, for example, with vinyl wallpaper, the risk of fungus appearing in the room increases significantly.

Material

First, let's clarify some issues related to the material of ceiling tiles.

Its correct name is expanded polystyrene. Often in review articles and even in store price tags you can see names like “polyurethane ceiling tiles.” Polyurethane is an extremely wear-resistant yellow polymer. Of course, it has nothing to do with ceiling tiles (see PVC ceiling tile).

Please note: polyurethane foam is known to all builders in the form of polyurethane foam. Strength is combined in polyurethane foam with excellent adhesion to any surface and excellent thermal insulation properties .

According to the production method, there are three different types of tiles:

- Injection polystyrene ceiling tiles are cheap and have low density with a thickness of 9 - 14 millimeters. The material is often called polystyrene foam, which is absolutely correct: polystyrene foam is the general name for all foamed plastics. The tiles are produced by sintering foam material

The production method allows us to produce tiles with a very complex relief surface.

- Stamped tiles are slightly denser; its thickness lies in the range of 6 - 8 millimeters. The production method follows from the name: the tiles are pressed at high temperatures.

- Extruded (extruded) polystyrene ceiling tiles are the most dense; its thickness is only 2.5 - 3 millimeters, and the surface is often laminated. The tiles are ideal for kitchens and bathrooms: the surface is smooth and easy to clean.

Extruded tiles with a laminated surface allow you to make the ceiling not only white: there is a wide range of colors available.

Choosing foam ceiling tiles

- Pressed or stamped tiles , the thickness of which is 6-8 mm. It is made from polystyrene foam blocks. The porous surface of this slab absorbs dirt, which is very difficult to wash off; it is easier to paint over it. It is not very practical to use, but it has a low cost.

- Seamless or injection ceiling tiles have the correct dimensions and a clearly defined pattern. The method of sintering raw materials helps to achieve this result. The high density of this type of tile allows you to create seamless ceilings. Disadvantages include the ability to absorb moisture.

- Extruded tiles have the highest price. It is made from pressed polystyrene strip, and then painted and laminated. The smooth, fine-grained surface of the tile allows it to be painted in any desired color if necessary. Extruded ceiling tiles have the highest hygienic properties.

When purchasing tiles for the ceiling, make sure that they are strictly square: even at the edges and straight at the corners. Carefully inspect the edges to ensure they are strong. It is extremely important that the polystyrene grains are the same size - this is an indicator of the strength of the ceiling tiles.

Selection rules

Polystyrene insulation is a popular and modern building material. Therefore, manufacturers do not miss the opportunity to make money on it. There are dozens of types of insulation sold on the market. How to choose the best polystyrene foam insulation?

Pay attention to the brand of material. A good indicator is 40, you can buy less, but not 25, since this is considered the lowest quality. An important stage of selection is technology verification

When choosing any products, you should adhere to GOST. There is no need to take risks and take insulation made using the manufacturer’s own technology, because the indicators may be much lower than the standard ones. For example, the PBS-S-40 brand may have a density of 28 instead of the stated 40 kg per cubic meter. As a last resort, ask for certificates that indicate the exact characteristics. Before buying a large batch, first buy one sheet and break off a small piece. The fault should form smoothly with regular polyhedra. The presence of large balls and irregularities indicates low quality of the material. Popular and already proven companies include: BASF, Polimeri Europa, Nova Styrochem, Chemicals and domestic ones - Technonikol and Penoplex.

Despite all the shortcomings and the difficult choice of insulation, expanded polystyrene is used in the construction of four out of five houses. He is trusted by most construction companies

If you take all precautions and follow technology, your home will be provided with heat for 30 years or more

Using foam ceiling tiles

Foam ceiling tiles are a universal finishing material because they can be used to decorate almost any room. Most often, ceiling tiles can be seen in the office, living room or bedroom. In these rooms, such tiles look especially advantageous due to their ability to visually increase the height of the ceiling.

Also, no less actively, such tiles are used to decorate the ceiling in the kitchen, but in this case they must have a protective laminated coating. For a children's room, you can choose ceiling tiles with a special layer of sound-absorbing material. For a toilet or bathroom, you can use smooth white ceiling tiles, or slightly corrugated ones.

Required Tools

To glue foam ceiling tiles you will need the following tools:

- laser level;

- stationery knife;

- putty knife;

- scissors;

- miter box;

- swing hand;

- square;

- roulette;

- meter ruler;

- leg-split;

- pencil;

- ladder.

Decorative tiles for the ceiling: installation methods

Finishing the ceiling with decorative tiles can be simply unforgettable.

The modern version of decorating the ceiling with decorative tiles is very popular. Of course, there are other materials, but this finishing method is justified for a number of reasons.

The main thing is ease of installation, which allows you to decorate the ceiling yourself. Although we note that not in every case you will be pleased with the low price of the material. But here, as they say, everything is relative, and what seems expensive for one person is a budget option for another.

That is why we will consider what types of decorative ceiling tiles there are solely for reasons of interior aesthetics. Let's talk about their advantages and disadvantages, possible installation methods and room design options.

Tiles for adhesive installation

Tile material differs not only in the material of manufacture, but also in the installation method. There are two such methods: glue and frame. It is the first option that is the easiest for independent work.

Having several products for a sample or ready-made molds, you can make gypsum tiles with your own hands

As for the cost of coating, the most affordable are polyvinyl chloride and polystyrene tiles. More expensive options are wood and gypsum tiles, as well as fiberglass boards, which can be mounted either with glue or with a subsystem. Depending on the size, the material is called tiles or slabs.

We present to your attention a selection of photos of interiors with different tile options:

As you can see, the choice of tiles both in terms of material and their front design is so wide that you can choose the right option for absolutely any room. All that remains is to find a good store.

Advantages of the adhesive finishing method

Finishing the ceiling by gluing tiles on it is the most common option, and not only in our country.

The reasons for this popularity are obvious:

- Gluing decorative ceiling tiles is quite simple;

- This method helps to hide surface defects, eliminating the need for major repairs;

- Often it is not even necessary to clean the base - polystyrene tiles are glued directly onto the whitewash or paint;

- Low cost of work, and often of the material itself;

- The procedure for gluing the ceiling with tiles will allow even a non-professional to do the job;

A black tiled ceiling is also very beautiful.

Since most types of tiles are produced in white and are subject to final painting, when decorating a room you can always go beyond the generally accepted ideas about design and make, for example, a blue or black ceiling. Next, a short instruction on laying tiles on the ceiling.

Secrets of ceiling cladding

If you glue the tile directly onto the old paint, it, of course, will not go anywhere and will stick. And it will hide small defects in the base.

Advice: However, if you want the seams to be smooth, or not visible at all when using seamless tiles, then the ceiling must first be cleaned: remove the plaster that is peeling off, treat the entire surface with a primer and putty it.

Gluing tiles over old flooring

- But there is no need to grind it to perfect smoothness. As for priming before gluing, whether to do it or not depends on the absorbency of the base and the type of glue used.

- Polystyrene tiles, like ceiling plinths, can also be glued to gypsum putty. If the tiles will be installed on a ceiling that has been puttied with it, then there is no need to prime. But if there was whitewashing, or vice versa, gluing is done directly on the concrete floor, then it is the soil that will ensure the best adhesion of the materials.

- But it is much easier to use universal glue to glue polystyrene foam tiles. Putty is usually used by craftsmen who can work quickly enough to finish the mixture before it hardens.

Laying tiles with a geometric pattern parallel to the walls

- When laying tiles on the ceiling, its edges can be placed parallel to the walls, or they can be placed diagonally.

- In order for the cladding to look finished, you need to use a ceiling plinth to frame the covering. It is also usually made from foam and polyurethane.

Do tiles have any disadvantages and what are they?

Recently, this method of simple and inexpensive ceiling finishing has already begun to go out of fashion. New modern technologies have appeared and competition has arisen.

Note: However, competition, as we know, is the most effective means of keeping a particular product from unreasonably rising in price. And also, it is precisely this that forces manufacturers to think about improving the quality and appearance of products.

What then explains the decline in popularity of polystyrene tiles?

- But the point is this: polystyrene - especially the cheapest one, with a granular structure, has such a nuance as collecting dust, soot and grease on the surface (if in the kitchen). If a smooth PVC tile can be simply wiped with a rag, then painted polystyrene, and even with a relief, cannot be washed off very well - you need to paint it again.

Advice! If you use polystyrene tiles with laminated film to decorate the ceiling, it eliminates these disadvantages. This is because its surface can be easily washed with any detergent.

In order for the edges of the tiles to fit perfectly together, the base must be level.

- In most cases, this type of finishing requires the presence of seams between the tiles. Therefore, the appearance at the surface is not entirely presentable. Even if the tiles are seamless, in fact the seams are visible in most cases.

- In addition, ceiling tiles are decorative and hide only part of the imperfections of the surface. Therefore, it will not save if there are floors with a large difference in height. On the contrary, such finishing will emphasize the existing defect.

As for the aesthetics of the coating, if you choose a beautiful and high-quality tile and glue it onto a well-prepared base, the result, as a rule, is excellent. These words are confirmed by the photographic materials and videos we selected in this article.

Features of a suspended ceiling

When installing hanging systems, decorative ceiling tiles are laid on a special lattice frame. Moreover, the distance between the false ceiling and the base surface can be significant.

The fact that these are suspended ceilings can only be guessed by the built-in lamps

Here are the features of such structures:

- A frame is used here, so the existing distance between the two surfaces can be put to good use. It is quite possible to hide water supply, ventilation system and any other communications in this space.

- If there are large differences in height and significant surface defects, they can be safely hidden. Therefore, the surface will be perfectly smooth.

- Considering the installation option without fastening, this is also beneficial. This is because the desired section of the ceiling can be repaired at any time, excluding global repair work.

- The most common case is when water pipes pass through the ceilings. The option of glued tiles involves replacing them: the damaged area is removed, after which the surface is puttied and everything is glued again. If it is a suspended tile, then you just need to remove the damaged area from the grate. Then replace the damaged material with a new part.

- The only sad thing here is that this type of ceiling decoration has all the disadvantages that are present in all suspended structures. To begin with, the height of the room will be lower by about 10-15 cm.

Therefore, if the room has low ceilings, then you need to think about whether it is worth paying attention to this finishing method, or whether it is better to give preference to adhesive cladding.

Types of tiles for suspended ceilings

Decorative tiles for the ceiling differ not only in the method of fastening, but also in the material of manufacture. The sizes of the slabs are most often standard, 500*500 mm or 600*600 mm, while tiles are usually twice as small.

In addition to the types of materials mentioned above, panels for suspended ceilings, which are more often called cassettes, can be made of glass and hardboard, aluminum and stainless steel, veneered plywood and laminated chipboard.

Akmigran tiles

Typically, Akmigran type tiles are used for fire safety and to ensure minimal hygroscopicity. It is made from granulated mineral wool, as well as with the addition of asbestos fiber. Moreover, the binding material is clay. Such tiles are produced using special technology by pressing.

The result is microcracks in the material, which gives the tile sound-absorbing properties. In addition, there is a high level of fire resistance. This material is widely used for cladding ceilings in theaters or conservatories. Indeed, thanks to this material, it is possible to increase soundproofing and also improve the acoustics in the room.

Plastic tiles

Ceiling tiles: lobby design - beautifully decorated plastic looks no worse than painted stucco.

Here we are talking about solid PVC and translucent acrylic material. The first option is most often installed in kitchens and bathrooms. Although, looking at the above example, it becomes clear that there are also slabs that can be installed in the living room.

As for acrylic ceilings, which are also essentially plastic, then, due to their light transmission, there is also the possibility of installing internal lighting. If you add diffused color, the effect is simply mesmerizing.

This makes the room visually tall. Therefore, this option is beneficial for small rooms.

An important advantage of such tiles is complete resistance to moisture. Therefore, after flooding, it is enough to simply wash it with soapy water. Therefore, this is an ideal option for bathrooms and kitchens.

Wood tiles

Veneered plywood ceiling

The most expensive type is a wooden ceiling. At the same time, its performance properties are much worse compared to all other types.

After all, wood is afraid of moisture, and can also burn and rot. Although, if you treat the material with an antiseptic and varnish it, some shortcomings can be eliminated.

However, due to the chic appearance of such tiles, some disadvantages are forgivable. If you use cork material, the coating will also have sound-absorbing properties.

Mirror glass tiles

Mirror tiles in living room design

This option is often used for rooms where it is necessary to expand the space. True, you need to work with such material carefully.

Particular attention should be paid to the strength of the frame, because the tiles have a lot of weight and sharp edges. Therefore, it is important to buy products from well-known and reputable companies that offer all the ceiling parts as a set.

Metal tiles

Tinted aluminum ceiling

If you install a ceiling made of metal modules in a room on the same frame, the system will last the longest. Since the material is not afraid of even high levels of humidity, it is often used in bathrooms, as well as on balconies and kitchens.

True, such a coating cannot provide good sound insulation. But as for the aesthetics of the interior, the design with ceiling tiles made of metal with a decorative coating will not leave anyone indifferent.

sdelaipotolok.com

Installation work

First of all, you need to immediately cut all the tiles into the required sizes. This can be done with scissors or a stationery knife, the main thing in this is to avoid any errors, since this can play a cruel joke on the evenness of the ceiling. The next step is to disconnect the electrical wiring. Work should be carried out with gloves so as not to stain the ceiling tiles. It is recommended to apply the adhesive pointwise along the perimeter and diagonals (about 25 points per tile).

Before attaching the foam tiles to the ceiling, you should let them sit for about 5 minutes so that the glue reaches the required conditions. You should start from the intersection of the marking lines. The edges of the tiles must clearly coincide with the marking lines. After which you should move forward from the first tile, thereby forming two perpendicular rows, and under no circumstances should you move away from the markings. Then, row by row, you need to glue the remaining rows. Once all the rows are completely glued, you need to attach the decorative border. In order for the corners to fit perfectly, it is best to use a miter box.

Ceiling cladding with decorative tiles

Finishing decorative ceiling tiles are made from polystyrene or expanded polystyrene. Tiles are available in various colors and shades, as well as with smooth surfaces and grooved or embossed patterns. The size of the tiles is 60 (3x600x9 mm or 300x300x9.5 mm. The weight of such tiles per 1 sq. m does not exceed 0.4 kg. Polystyrene tiles They are durable, resistant to moisture, and easy to glue. Moreover, if you decide to change the color of the ceiling, they can be painted with water-based paint. Paints based on organic solvents cannot be used, since they also dissolve polystyrene. Caring for such tiles is extremely simple - they are easily washed with water with the addition of detergents. You can dry clean the ceiling with a vacuum cleaner. Polystyrene tiles do not rot and also retain heat in the room perfectly. Tiles made of polystyrene foam have the same positive qualities as polystyrene tiles They have a silky matte surface that imitates various materials (wood, stone, sand, etc.).Ceiling tiles can be used in combination with cornices and rosettes made of the same materials.Preparing the surface for gluing panels is carried out according to the following rules :— painted surfaces should be cleaned of dust and dirt;— peeling or flaking areas of the painted surface should be cleaned;— large cracks and holes should be filled with plaster;— the chalk coating should be removed, since it is impossible to stick tiles on it;— after cleaning the ceiling from chalk it should be covered with primer so that a strong film is formed on the surface. It is best to start pasting the ceiling in such a way that the central tile is located directly in the center of the ceiling. To make it easier to determine the central point of the ceiling, you can stretch the threads diagonally from one corner to another. The intersection of the threads will be the center. In order to draw parallel lines, which should be guided by when pasting, you need to draw strictly perpendicular lines to the walls from the marked center of the ceiling. Next, measure the tile and mark a distance on perpendicular lines equal to half the length of the tile. The first tile is glued along these marks. It is recommended to glue the remaining tiles butt to the first in parallel rows. It is unlikely that a whole tile will fit on the steppe. In this case, it should be trimmed with a knife or thin file. Measure the required distance on the tile, draw a pencil line between the marks on the back side of the tile and saw off or cut off the excess part along this line. The glue is applied to the back side of the tile and to the surface at the same time. To apply the glue, you can use either a regular spatula or a spatula with small rectangular teeth. 4-6 minutes after applying the glue, the tile should be pressed tightly against the ceiling surface and held for 1-2 minutes. The glue must be specifically suitable for this type of tile. This glue cannot be made at home. The type of adhesive is usually indicated on the instructions for use, which must be included with the set of tiles.

Cornices made from the same materials are glued to the walls close to the ceiling after finishing work on the ceiling and walls is completed. It must be said that, unlike finishing with paint or wallpaper, ceilings made of decorative slabs can be glued after finishing the walls.

ru-stroyka.com