You won’t surprise anyone with standard solutions for decorating walls inside or outside the house. Owners of residential premises today are trying to approach finishing work with imagination. And decorative plasters help them with this. The word plaster itself came into Russian from Italian, which means alabaster. Therefore, decorative plaster must have all the qualities and properties of this material. That is, it is easy to apply and durable after drying.

The composition of decorative plaster itself should be identical to conventional plasters, where the main components are cement, sand, lime, and gypsum. True, there are also serious differences - various fillers can be added to decorative plaster, for example, pebbles, fibers, granules, and so on. True, not all types add these items. A modern approach to the production of plaster mortars will allow you to purchase ready-made or dry mixtures.

Types of decorative plaster

Nowadays, when purchasing decorative plaster, you can be sure that you will get a different texture on the wall. It can be a smooth surface, embossed, glossy, or an imitation of almost any natural material. And all this can be done with your own hands without much effort.

Decorative plaster should be divided into types according to its components. And if we take fillers as a basis for dividing, then decorative plaster is divided as follows:

- Structural;

- Textured;

- Venetian.

Structural and textured belongs to the category of relief surfaces. Because their main difference is the rough surface of the wall. Venetian is a very smooth wall without bulges or dents.

Surfaces for applying decorative plaster

The finishing material for this type of finishing can be applied to any type of surface, be it brick, concrete, wood or drywall. Thus, it is suitable for almost any room and surface - feel free to use it in the bathroom and kitchen, and if desired, you can apply it to the ceiling.

Currently, interior decorative plaster has many different application methods. The most commonly used material is one that has a fine-grained structure. It is applied, as a rule, using a special sprayer, spatula or roller.

Types by binder

It should be noted that modern production of building materials can no longer do without polymers. And decorative plasters are not spared these synthetic substances. Therefore, on the market today you can find both mineral and synthetic types. Here are the main types of decorative plaster, which are based on different binding components.

- Mineral. This type is based on cement. In terms of its strength, it is one of the most highly durable materials, but if we talk about heavy loads, cement types do not tolerate them well. Therefore, it is not recommended to wash external walls finished with cement plaster under high water pressure. Let's add that this is the most environmentally friendly option. It can be used for finishing external walls, as well as internal ones in damp rooms.

- Acrylic. The mixture is based on a high molecular weight polymer – acrylic resin. It is the resin that gives the plaster mortar a high degree of elasticity. But at the same time, the solution has several disadvantages: it is afraid of sunlight, under which it begins to crack, and has low vapor permeability. Therefore, acrylic types are not recommended for use in all rooms, much less outdoors.

- Silicone (see photo above). Polymer is also used here - these are synthetic resins. The owner of a huge list of advantages, where it should be noted, ease of application (with your own hands - no problem), high elasticity of the material, great resistance to sunlight (therefore, silicone types can be used for finishing facades without fear). It is also necessary to add good moisture resistance; the solution has no foreign odors and does not attract dust. This is an ideal option for exterior wall decoration.

- Silicate. The mixture is based on liquid glass. Composition of liquid glass: potassium hydroxide, alkaline potassium carbonate and quartz sand. The surprising thing is that all these components belong to different materials and perform different roles. One is an astringent ingredient, another is an absorbent, and the third is a filler. Therefore, this type of plaster is the most durable, plus it has good vapor permeability, good fire resistance, and you will never see mold or a colony of fungi on this layer. Therefore, silicate species can be used in all rooms and for finishing facades.

Types of textured plaster

Decorative plaster may differ in the structure of fractions, the resulting relief, the quality of auxiliary additives, as well as in other parameters, but the main classification is considered to be the division according to binders or bases. This parameter is a priority, since the type of finishing mixture is selected in relation to it.

Textured plaster, photos of relief options and design solutions:

Textured plaster in the bathroom

For a detailed study of the stages of finishing work, a master class on applying textured plaster is published at the end of the article, but even if you strictly follow all the recommendations, but at the same time use a solution that does not correspond to the structural features of the wall, there is a high probability that the result will be unsatisfactory. Possible defects due to violation of application technology:

- cracks;

- bloating;

- peeling, and other deterioration of the properties of the material.

For example, if the wall is made of aerated concrete, which is characterized by high porosity, then a prerequisite for the textured plaster used is high vapor permeability. Otherwise, moisture will accumulate and gradually destroy not only the coating, but also the structure of the wall itself. In this regard, it is very important to correctly select the solution for plastering, and most importantly, its base.

Classification of textured plaster for walls

- Mineral. The starting material is a dry mixture of cement, which is the main binder, as well as other auxiliary components to give better elasticity and relief. This textured plaster is recommended for use on similar mineral surfaces;

- Silicate. The binding base is special liquid glass. It is characterized by high vapor permeability and is considered universal, as it is used on almost any surface and is resistant to various types of influences, which is reflected in the price. Sold in a form ready for application to the surface;

- Silicone. Reliable adhesion is ensured by synthetic resins. Working with textured plaster of this type is quite simple, since the material is very plastic. In addition, the silicone mixture is suitable for both mineral and other types of building structures. Plaster is used not only for premises, but also for facades;

- Acrylic. The material initially has a consistency ready for finishing work. The coating is ideally combined with mineral substrates, such as concrete, as well as with other standard substrates. The binding component is acrylic resin.

The composition of decorative plaster, endowed with textured properties, as well as recommendations for its use, are most often reflected on the packaging itself. In addition, additional information can be obtained from a consultant at a retail outlet or online store.

Textured plaster

This variety has a highly viscous structure, one might even say coarse. Cotton, flax fibers, pieces of wood, mica, small stones, granules of marble or granite chips may be present as fillers. Used for both external and internal decoration of walls with your own hands. Can be applied to almost all surfaces except drywall (see photo).

Since the mixture contains coarse fillers, the applied layer must be thick enough. And this is a kind of plus, because it is possible not to pay attention to the quality of the base surface of the wall. Decorative textured plaster will cover all unevenness and defects on its own.

Main positive characteristics:

- High strength;

- Almost zero water permeability;

- Good breathability.

It should be noted that textured plaster is the most common and popular among all types offered on the market. Has a reasonable price. Applying it to the wall with your own hands is not difficult.

The material is sold ready-made in 9 and 18 kg buckets (see photo), or dry in 50 kg bags. Consumption per square meter of surface up to 2 kg. But the larger the filler, the greater the consumption.

Attention! Textured plaster can only be used at temperatures not lower than +7°C. If it is applied to the facade, then work cannot be carried out in rainy weather.

The textured variety has its own subtypes, which differ from each other in purely external design indicators.

- Fur coat. The surface of this finish has a high roughness, which strongly resembles hairiness. The binder is cement.

- Lamb. The mixture contains coarse fillers (pebbles, stone granules). The surface is obtained with uniform, often alternating convexities, such a uniform grain size.

- Bark beetle The applied texture mixture will look like corroded tree bark. Here she is in the photo below.

The textured variety has one specific property - it creates a structure that appears immediately after applying the finish. In addition, these types can be painted after application or added color during the preparation of the material.

Textured plaster in the interior: examples

Textured plaster for walls looks very aesthetically pleasing and advantageous, which we will illustrate with our photo selection. Depending on the color scheme, type of mixture, application technology, you can choose a texture suitable for any interior style. And thanks to the practicality and wear resistance of the coating, it can be used not only for “dry” areas in the apartment, but even for the bathroom and kitchen.

Examples of using plaster in different rooms:

- Kitchen. You can decorate with textured plaster not only the surface of the walls, but even the apron area.

Kitchen plastered to look like mud. The texture also resembles the effect of crumpled paper.

- Bathroom. Due to its excellent antistatic properties, vapor permeability and resistance to detergents, decorative plaster is successfully used in the decoration of bathrooms.

For a bathroom, you should not choose a very deep texture - these numerous depressions will retain water, which will ultimately lead to a decrease in the service life of the coating.

A smooth marble texture was chosen for wall decoration.

- Bedroom. In the decoration of living rooms, textured plaster opens up enormous opportunities for the implementation of design solutions and ideas. For small bedrooms, it is not recommended to choose large and “heavy” textures. But a discreet pattern and light color scheme will come in handy.

Not only the walls, but also the ceiling are finished with plaster.

- Living room. This material is a win-win for finishing the living room.

Textured plaster of a delicate gray color harmonizes perfectly with the white stretch ceiling and matching furniture.

Thus, we examined the main features of textured plasters for finishing walls inside and outside the house with photo examples. The use of textured plasters is an opportunity to create a unique space design and obtain an aesthetic, high-quality, durable coating.

You can learn more about the types of decorative plaster from the video:

Related publications

- Read

Types and photos of decorative plaster in the kitchen interior

- Read

Review of “lamb” plaster: photos and videos of houses, tips for application

- Read

Calculator for plaster consumption per 1m2

- Read

Wet facade technology

- Read

DIY wall decoration

- Read

Structural plaster

On the contrary, it is a thin-layer texture. The material is based on acrylic or silicate. Manufacturers most often use either quartz or marble chips as fillers. On the wall, the layer looks like a non-uniform granular surface (see photo below). If the filler has very small grain sizes, then the texture of the finish may look completely smooth.

Advantages of this type:

- Good strength;

- Excellent breathability;

- Plaster is not afraid of moisture;

- It goes on sale ready-made, without the need to add dyes.

Sales containers – plastic buckets of 9 or 18 kg. Consumption per 1 m² - 3 kg. It’s easy to apply the solution with your own hands. You can work with the material only at a temperature not lower than +7°C in rooms with low humidity and outdoors in good weather, not rainy. By the way, fences are often finished with this material.

Attention! If structural plaster will be used indoors, it is recommended to choose a water-based mixture.

It is odorless and dries quickly. This surface can be cleaned with soapy solutions.

How to make textured plaster

There are no particular difficulties when creating textured plaster; the main thing is to follow a certain sequence, which looks like this:

- Surface preparation. The wall is cleaned of previous finishing and associated contaminants;

- Padding. The product is applied in an even layer for better adhesion;

- Applying a layer of plaster, and, if necessary, forming a relief or pattern. What configurations there will be depends solely on imagination and the devices used; the main thing is to carry out all these manipulations within 30-40 minutes, otherwise the solution will begin to harden. In some cases, it will be necessary to apply several layers, for example, if the wall has a large number of defects or it is necessary to create a deeper texture with combinations of several shades at once;

- Coloring. If a solution of the desired color was initially used or was additionally tinted, then this step is omitted.

At the final stage, when the coating is completely dry, you can adjust the relief with a special hard grater. It is also possible to impart a matte or specific shine to the surface using appropriate processing agents.

If you are not sure that all the work can be done yourself or there is no time for finishing activities, then it is better to contact a professional construction and repair company. You also need to pay attention to the quality of textured plaster, which must be purchased only in specialized stores and not from private individuals. The product must be accompanied by instructions indicating the preparation proportions, consumption and average drying time of the solution.

Venetian plaster

This is, so to speak, premium material. It is based on two main components: slaked lime and marble chips. The plaster is applied in several layers, resulting in a homogeneous structure on the wall (see photo below). This technology was known back in Ancient Rome, when waste from sawing marble - small particles and dust - was added to the plaster solution.

The final finish after drying is very similar to marble or onyx cladding. And if we talk about the correct application of plaster, then extensive experience in carrying out this type of work is required. A beginner cannot immediately master it with his own hands. The application technology, although simple, requires special diligence and accuracy. The mixture is applied to the wall in small strokes in several layers, each of which must be thoroughly dried.

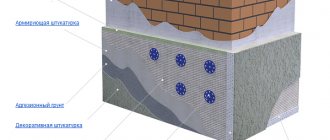

Depending on how you apply the material to the wall, you can get a glossy or matte look. Since Venetian plaster itself is a fairly expensive material, the attitude towards preparing the surface to be finished is very strict. Experts recommend first repairing it, strengthening it with a reinforcing frame, leveling and priming. Let's face it, for someone who decides to carry out this process with their own hands, they will have to try very hard.

Typically, this method is used to decorate rooms that are decided to be decorated in an antique, baroque or classic style. It is allowed to paint the applied plaster in any suitable color. The material itself is sold only in finished form in containers of 8 or 16 kg. And one more thing - Venetian plaster can only be used for interior work.