Entrance plastic door structures for a private house

PVC entrance doors for a private or country house have found their application quite recently and are now often in demand and presentable. The convenient and reliable use of these structures serves as a guarantee for all consumers. The popularity of metal-plastic entrance doors is well deserved, as it has a huge number of positive characteristics.

9 door characteristics:

- The appearance of the entrance metal-plastic models adequately represents the beautiful appearance of a private home and is the main attribute of order during the initial visit.

- There is a relatively small price category in comparison with metal or wooden models of entrance doors.

- Allows you to choose the optimal design solution and perfectly reflects taste preferences in combination with the overall exterior.

- Easy and simple care helps to quickly clean contaminated areas of the structure using ordinary water and soap, without resorting to complex cleaning compounds.

- It has suppressive noise ability, which reliably protects against irritating street noise.

- The excellent thermal insulation of plastic models guarantees against the penetration of cold air into the interior of the room.

- Thanks to the built-in metal profile, the door structure is very strong and durable.

- It is not subject to the development of mold, fungi and harmful effects of moisture, unlike wooden structures.

- Plastic structures are made of environmentally friendly material and do not cause harm to humans and the environment.

When choosing metal-plastic doors and further installation of structures, you must contact specialized, trusted stores that can provide professional advice and provide a guarantee and quality of these products.

Options

Such designs can be:

- Balcony.

- Interior.

- PVC entrance doors for a private house.

Many people do not understand the difference between an entrance door and a balcony door. Their development should be the same. In general, everything is identical, but the emphasis is not on protective functions, but on ventilation. Therefore, by installing such a structure in an apartment, everyone receives several positions in which the microclimate in the entire home is improved. At the front door, the task is to protect residents from intruders entering the house. Therefore, the emphasis is on the strength and reliability of the structure.

It is often necessary to install a blind door in a room through which nothing can be seen. Depending on where it will be located, insulation may be provided inside the structure. For exterior doors, it is important to get an additional barrier to prevent cold air from entering. Often such doors are found in bathrooms, since their level of hygiene is high and the cost is affordable.

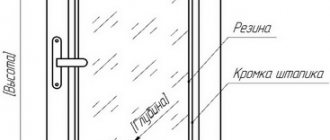

Structural elements of metal-plastic doors

The main component of metal-plastic doors is a PVC profile containing hollow chambers inside. The number of chambers located in the profile usually determines the degree of thermal and noise insulation. The standard arrangement of internal cavities consists of three, five and seven profile chambers inside. This model includes the following structural elements.

Structural components for plastic doors:

- The profile frame determines the strength of the structure and contains a metal frame inside, which serves as an amplifier. The corner joints of the door profile frame are joined with special connectors to a reinforced surface, which increases the rigidity of the product.

- The door leaf is made of PVC raw materials with an internal metal frame, but differs in profile configuration. The door cavities are filled with heat-insulating material.

- Double-glazed windows and their presence in door panels are provided quite often. In the manufacture of double-glazed windows, triplex or armored glass is used. The glass unit used in the door leaf must have a strength much higher than the window structure.

- The shutter mechanisms of the door leaves are located around the perimeter of the entire leaf and allow for tight pressure along the entire plane of the product.

- The threshold in the manufacture of a plastic door can be made not only from PVC raw materials, but also from various metal alloys. There is also a rubber seal in the threshold that ensures the tightness of the product.

- The fittings are used for comfortable use of the product and include locks, handles, hinges, and if there is a need to control the opening of the door, then a closer.

The production of metal-plastic doors has complex production technology. The use of high-quality fittings is also of great importance in operation. You should pay attention to the production of fittings, since the durability and quality of the product in use depends on this.

Installing a PVC entrance door with your own hands. Step-by-step instruction

To choose the right door, you need to carefully measure the dimensions of the doorway. Once the doors and frame have been purchased and delivered, installation begins. Here's the procedure:

- The frame with the doors removed is inserted into the opening. On each side, two wedges are driven into the sides for fixation. Then a level check is carried out. The position of the mounting holes is marked on the walls.

- Holes for dowels are drilled in the walls of the opening.

- Dowels are placed in the holes. The frame is screwed to the dowels, controlling the level of verticality.

- The door panels are put on, the travel and pressure are checked. The hinges are adjustable if necessary.

- Locks are installed and a final check of the operation of all fittings is carried out.

- The space between the frame and the walls of the opening is foamed. Additional elements are being installed and the slopes are being finished.

Installation of doors with glazing units requires special care. If you move incorrectly, it is easy to damage the double-glazed windows.

How to install interior doors yourself

Self-installation of plastic interior doors is a rather labor-intensive process and requires a lot of attention to various installation details. The further trouble-free use of the product depends on high-quality installation. Before you begin installation, you must have a special tool and an understanding of the installation steps of installing doors.

Several recommendations for installing interior plastic doors:

- As a rule, they are installed in an existing doorway, which may have an outdated design. Initially, you need to make sure that the dimensions of the doorway match the dimensions of the new product, naturally taking into account installation gaps and distortions. If necessary, dismantle the old structure and prepare the opening for installation of the plastic structure.

- The next stage is preparing the new structure for installation. It is necessary to ensure that the door hinges are properly crimped and check the functionality of the locking mechanisms. When transporting structures, some technical damage, abrasions or defects are possible and that is why you need to carefully check the entire product.

- When installing it in the opening, it is necessary to clearly set the horizontal, vertical and plane, as well as the uniform depth relative to the internal and external walls. Be sure to follow the diagonals of the door frame, which must coincide at both corners. Incorrect alignment of the diagonals can lead to jamming of the shutter fittings and problematic use of the door.

During the fastening process, make sure that there is no deformation of the door profile, various deflections and distortions of the door structure.

When using fasteners, you should make sure of their quality and reliability, since the plastic door structure must be stable and withstand the load of its own weight.

For high-quality installation of metal-plastic interior doors, it is recommended to contact professionals who know the installation technology and receive a quality guarantee for the further use of the product.

Operation of such doors between rooms

Light interior door made of plastic

Interior doors made of plastic have significantly surpassed wooden ones in popularity. After all, their price and some characteristics are much better.

Plastic structures are fireproof. Therefore, you don’t have to worry about them catching fire or melting at high temperatures. Plastic doors have good moisture resistance. They can be installed in the bathroom, kitchen or shower. They are also often installed in rooms with variable humidity.

One of the main advantages of interior plastic structures is excellent sound insulation, which is especially important in limited spaces.

Using them on the balcony

Original balcony and plastic door

Balcony doors made of plastic have become very popular lately. A balcony block can consist of a balcony door with one or two windows that separate the room from the loggia. Such a plastic system can consist entirely of glass, plastic, or be covered with plastic in the lower part. The third option is much more common. It is more economical and aesthetic.

Types of plastic doors

Any architectural, technical and residential building is characterized by door and window structures of various design developments. Whether it is a new building or an old building with an entrance to the veranda, there is always an entrance door. When choosing one or another door design, each model has its own type, design and technical purpose, divided into several types.

3 types of plastic doors:

- Input;

- Balcony;

- Interior models made of PVC.

The main types of plastic structures have many technological differences in the opening method and partitions.

Types of plastic doors:

- Double or double leaf;

- Single leaf;

- Arched;

- Sliding;

- Swing;

- Foldable.

Such models have the best design options and are manufactured using the best technology. Almost every family has metal-plastic structures, be it windows or doors. Manufacturers guarantee safety and reliability for many years of operation. Most buyers choose metal-plastic structures because they are of high quality and quite inexpensive, which almost everyone can afford.

Video: what you need to know to choose the right PVC doors

Excellent heat, sound insulation and high decorative properties

allow the use of plastic doors as entrance structures for both retail and office premises, as well as private houses and cottages.

Doors are the most important structural and decorative element

building exterior.

Despite the fact that plastic structures are less durable than metal doors, spectacular and visually attractive PVC products are widely used for arranging the entrance areas

of secure office and industrial premises and private houses equipped with reliable alarm systems.

Such doors are installed not only at the entrance to the house, but also to the swimming pool, winter garden, garage and other buildings.

Polyvinyl chloride (PVC), which contains special stabilizers, can withstand very significant temperature changes

and is a very moisture-resistant and durable material. Reinforcing plastic entrance structures with metal inserts allows you to reliably protect the premises from illegal entry.

Features and problems of plastic structures

During the period of operation of PVC doors, owners may notice some shortcomings or problems in use. When closed, they let in cold street air, the movement of the sash becomes difficult when closing and opening, the double-glazed windows fog up, and it blows from the slopes.

First of all, such phenomena are caused by the following reasons:

- Unprofessional installation of a metal-plastic structure;

- Incorrect use of the product;

- Defects in production;

- Use of low-quality door hardware.

Feedback about installer errors:

- The door structure is not installed level and this causes the door to rub when opening or closing, fragmentary damage to the door fittings, and loose fit to the entire plane. Water ingress and accumulation in the profile, as well as moisture ingress into the room. To eliminate the problem, it is recommended to thoroughly reinstall the door structure.

- Improper execution of the installation gap or seam causes the formation of cracks in areas adjacent to the window sill and slope, freezing of the internal slopes and window sill. In such cases, it is recommended to correct the assembly seam of the structure.

- An insufficient number of fastening points can cause deflections in the door frame and distortion of the entire structure. In such cases, it is necessary to increase the number of fasteners and carry out the installation again.

- Damage to the glass entails the complete production of a double-glazed window, since one glass cannot be replaced according to manufacturing technologies. To replace it, you need to take an exact measurement of the damaged glass unit and send it to production.

PVC plastic doors require some care for fittings and rubber seals, which tend to wear out quickly. Construction debris falling on the moving parts of the fittings can cause damage to the door structure.