Control cabinets (CC) and automation cabinets (CA) are low-voltage complete devices designed for collecting and processing information from sensors, controlling electrical equipment, and transmitting data to the information network of the dispatch system.

produces control and automation cabinets SHU that meet the requirements of TR TS 004/2011 and TU “Automation and control cabinets for technological equipment ACU”.

Control cabinets (CC) and automation cabinets (CA) can be manufactured according to our own circuit diagrams or diagrams received from the customer. If the electrical circuits are provided by the customer, they undergo a thorough audit for operability and compliance with regulatory documents (PUE, industry GOSTs and SNIPs).

Manufactured control and automation cabinets are being implemented at various enterprises in the fields of energy, industry, construction, mining and transportation of minerals, petrochemicals, and housing and communal services. The equipment has certificates of compliance with technical regulations on fire safety requirements and the safety of low-voltage equipment.

The choice of ШУ and ША brand and custom code depends on the number of controlled and adjustable parameters, the complexity of the technological process, the types of actuators, the need to transfer data to upper-level systems and other requirements of the customer’s technical specifications.

Types of equipment offered

On the page “production of automation and control cabinets and panels” process control cabinets and automation panels are presented:

- distributed control system DCS;

- technological processes;

- ESD emergency protection;

- pumping stations and pumps;

- dispatch systems;

- energy accounting ASTUE, ASKUE;

- gas control;

- ventilation systems, heating points, air pressurization and smoke removal fans;

- fire pumps, valves, channels;

- power supply and lighting systems;

- telecommunications;

- cross cabinets;

- server;

- Main switchboard, RP, AVR, ASU.

You can purchase a standard SHU control cabinet with a standard configuration, according to the completed questionnaire, or a non-standard one according to individual requirements.

ACU series cabinets are made from European components and are of high quality.

Together with the control and automation cabinet (CA), each buyer receives a set of documents for the product, where the attached passport reflects electrical diagrams, warranty obligations, and instructions for use.

Design Features

SHU cabinets differ in that they include power circuits and control circuits. Control cabinet diagrams include the following elements:

- Power supplies;

- controllers, input and output modules for discrete and analog signals;

- circuit breakers;

- network communication modules;

- touch panels (optional);

- contactors;

- electromagnetic relays;

- two and three position switches;

- buttons;

- indicator lamps;

- terminals.

Functions performed

The operating principle of control cabinets (control panels) is based on:

- constant monitoring of changes in the technical characteristics of the system recorded by sensors;

- mathematical processing of the received data by software installed in the controller;

- generating control signals to turn equipment on and off (pumps, compressors, valves, etc.) and setting their operating modes;

- implementation of visual monitoring of the state of technological processes.

The main functions of SHU control cabinets and ShU automation cabinets include:

- equipment diagnostics and protection;

- automatic equipment control;

- switching between manual, semi-automatic or automatic operating mode;

- implementation of dispatcher and operator commands;

- precise adjustment of technical parameters of engineering systems or technical processes (temperature, pressure, etc.);

- transmission of telemetric data to the operator panel or operator monitors in the control room;

- visual and remote monitoring of changes in the values of monitored parameters;

- light and sound alarm (working, warning, information, emergency);

- automatic protection in case of an accident;

- blocking the switching on of equipment in the event of a repetition of the emergency.

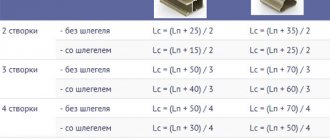

How to choose an aluminum profile for a wardrobe

As an advertisement

Now this piece of furniture is in almost every house or apartment, which, however, does not make it trivial. The popularity of sliding wardrobes is dictated, first of all, by the fact that they allow you to perfectly optimize space and store a lot of necessary things in a limited area, while being not only a convenient and stylish piece of furniture, but also in each case a unique element of the decor, in the creation of which the user is directly involved.

Cabinet design must begin with the choice of material. Not only the appearance, but also the service life and ease of use depend on this. One of the key components and the most important element of any wardrobe is sliding doors, namely their opening mechanism, the choice of which should be approached as responsibly as possible. Firstly, during use they will be subject to physical impact dozens of times a day, so the sliding door system must withstand such loads. Secondly, doors are the face of the cabinet, and the profile framing the door leaf should look harmonious and presentable.

One of the most common materials for making profiles is aluminum. Aluminum profiles have enviable durability and low weight. In addition, during operation they are less noisy than their steel counterparts.

Typical problems that users encounter when choosing aluminum profiles:

- Promoted European brands are very expensive and are not represented by a sufficient range due to the lack of wide distribution. Hence the high cost of the finished product and the insufficient number of colors and decors, which limits the possibilities of using the profile in “designer” interiors.

- Some domestic manufacturers, in order to reduce costs, simplify profile designs, which entails the unreliability of the sliding door system and its fragility. It happens that the profile is made with a thickness of 0.8 mm, while the structure does not have additional reinforcements, which, again, can lead to deformation of the door and other defects.

- There are also many complaints about the durability of the decorative coating of domestic profiles. It is often made poorly and is subject to abrasion and fading during use.

At the same time, many shortcomings appear precisely during operation, when the cabinet is already assembled, and replacement or repair is very problematic and costly. To get rid of possible negative consequences, you should choose a reliable and reputable manufacturer.

GRANDIS has been one of the leading domestic manufacturers of aluminum profiles for furniture cabinets and sliding doors for more than 15 years. Modern high-tech production facilities plus careful quality control and a creative approach allow the company to satisfy the needs of the most sophisticated customer.

In the manufacture of profiles and components, only high-quality aluminum alloy from primary raw materials is used, and GRANDIS high-precision equipment allows you to be confident in the quality of the finished product. Accurate calculations and perfect adherence to dimensions allow us to achieve maximum ease of assembly and reliability in the use of furniture systems. Strict adherence to production technology and quality control at all stages completely eliminate the possibility of defects.

The GRANDIS profile is available in two series: Premium - profile wall thickness 1.2 mm, and Ecolight - wall thickness 1 mm. At the same time, the design of the lightweight Ecolight profile has been improved and strengthened, which guarantees its reliability and durability.

Also in September of this year, the company’s product range included a new system for sliding doors with a thin profile, NEO-Light, which allows doors to be assembled in a narrow frame with a minimum amount of visible aluminum frame. The width of the front part of the profiles is only 10 mm, and the lower rollers, thanks to design features, are hidden in the body of the product. The visible parts of the vertical and horizontal profiles are located at the same level, resulting in a thin, solid frame framing the door. The NEO-Light system meets the latest trends in furniture design and fits perfectly into any modern interior.

Compared to most domestic analogues, aluminum profiles from GRANDIS have a number of advantages:

- Profiles are universal. The same vertical profile configuration can be used in all offered systems: sliding-bottom support, sliding-suspended, folding-suspended and hinged. That is, it doesn’t matter at all what operating principle of the sliding mechanism the customer chooses for himself; he can use the vertical profile of the configuration he likes without any problems or additional searches.

- During production, the entire profile goes through the stage of processing with fine shot, which gives it a perfectly even color without tints.

- The groove design of vertical profiles deserves special attention. It is no secret that the quality of door leaf milling sometimes leaves much to be desired, and the thickness of the door leaf edge may differ from the established standard dimensions. Then, when assembling the sliding doors, it will either be loosely fixed, or the vertical handle profile will be tightly pressed onto the slab. With GRANDIS profiles, the groove for the sheet narrows closer to the inner wall, thereby reliably fixing the slab material in the vertical frame.

- Special technology for the production of premium profiles guarantees its increased resistance to mechanical damage during transportation, assembly, and operation of the finished product.

- A separate advantage is the widest range, including 8 types of handles in 22 decor options in various price categories. From the most budget ones - the V handle, which allows you to assemble doors from 16 mm leaf without using the upper and lower horizons, to the presentable profiles of the Premium series. The company's product range includes the widespread and popular C and CL-shaped handles, interestingly shaped symmetrical vertical profiles RH and 2H, as well as a number of exclusive and patented developments, such as the H-shaped handle, sliding-hanging, folding-hanging and hinged elements systems, etc. The customer can choose a handle with one (C, CL, V) or two (H, 2H, RH) working surfaces. The last three types of vertical profiles can also be used in the manufacture of interior doors and partitions. Also, handles H, 2H and RH can be additionally decorated with furniture edges of standard sizes, for example, in the color of the cabinet or, on the contrary, in a contrasting color.

At the same time, GRANDIS products correspond to the quality of European analogues and significantly exceed them in terms of affordability.

The company has its own warehouses in the Moscow, Samara and Rostov regions and carries out wholesale deliveries throughout Russia. You can purchase products at retail from GRANDIS dealers and partners in the regions.

Advantages of cooperation with us

Cooperation with will provide you with the following benefits:

- guarantee of the quality of goods and services;

- highly qualified specialists;

- efficiency of order execution;

- affordable prices from the manufacturer;

- expert technical support during project development;

- drawing up individual control schemes or providing standard solutions;

- technical support during commissioning.

The cost of a wall-mounted control cabinet will be based on the number of control and monitoring signals and the level of development of functions. You can find out exact prices from specialists by phone or email by sending a request: .

Sliding door opening systems

A fundamentally different way of installing facades on furniture bodies. The doors are not attached to the body in any way, but slide along guides installed on the body. In this case, the sash itself can simply be moved to the side or folded. Or wound on the shaft.

Sliding doors

Sliding opening systems operate on the “compartment” principle; the door slides along guides to the left or right. Their disadvantage is that in the end we get limited access to the internal filling of the cabinet - exactly the width of one door.

There are two types of sliding systems – suspended and supported. The latter are also called roller.

Accordion doors

Their advantage over compartment doors is that we get full access to the interior of the cabinet. But this requires space in the front of the cabinet to fold the doors forward. But the compartment doors move in the same plane.

Furniture blinds and roller shutters

They are used in furnishing furniture much less than they deserve. The reason is that to install them, you need to allocate space inside the cabinet for the shaft on which the facade will be “screwed”. This is not always acceptable, especially in kitchens where every shelf is important.

Electric blinds are a new opening mechanism for kitchen cabinets. It looks very impressive and works without a shaft. But, like all mechanisms powered by an electric drive, it is not cheap.

Comprehensive process automation service

Our company provides services for the design and implementation of automated, low-current and electrical systems.

The full cycle of technological operations includes the following processes:

- development of technical specifications;

- development of design and working documentation;

- support during the technical examination of the project;

- production of control cabinets (CC) and automation cabinets (CA);

- development of application software (ASW) for controllers (PLC) and automated workstations (HMI);

- installation and commissioning of equipment by experienced specialists;

- maintenance of systems, provision of advice on any issues.

Over a long period of activity, our specialists have completed technically complex turnkey automation projects: from the formation of technical specifications and design to the commissioning of the system. In the process of work, the current standards of PUE, GOST, SNiP in the field of electrical engineering and automation systems are observed. Control cabinets (CC) and automation cabinets (CA) meet fire and explosion safety standards, PUE standards and undergo factory testing and final inspection.

How to install doors on the headset body yourself ↑

The appearance of the modules and the ease of their operation depend on the correct installation of the doors for the kitchen unit. If mistakes are made during installation, then even the most beautiful facades will look untidy, and the impression of the furniture will be hopelessly spoiled.

Advice. Learning how to hang hinged doors on cabinets is useful, but the ideal option is to entrust the assembly of the set to professional craftsmen. If you are not confident in your abilities, do not take the job.

Professional kitchen assembly

- Calculate the required number of loops and select the appropriate type of fittings. If the cabinets are standard sizes, two to four hinges for each door are sufficient.

- Attach the hinge cup to the door and the strike plate to the cabinet body, as shown in the photo below. Self-tapping screws, bushings, and Clip quick installation systems can be used as fastening elements.

- Hang the door on its hinges, starting from the top. Make sure that the screw head fits into a special guide, if it is provided for in the design of the selected hinges.

Advice. Usually, there are no problems with installing kitchen doors, but there are some nuances. For example, to hang narrow doors it is better to use a short screwdriver. If there are more than two loops, it is more difficult to install the facades, but this task can be completed, especially if you have an assistant.

Hanging the facade on hinges