I have long dreamed of a transforming table; in our Khrushchev-era buildings it cannot be any other way. All rooms are always filled with furniture and all sorts of things. I wanted to somehow reduce the amount of furniture, but not lose functionality. I found the answer to this question a long time ago in transformable furniture, but it was expensive to buy, and I didn’t dare make it myself.

There was a period when I collected all the materials and was already planning to make a table, but when faced with the first problem - making or buying a transformation mechanism - I immediately abandoned the idea. And I suddenly returned to the idea of assembling a transformer table with my own hands - the living room was undergoing renovation, it was assumed that after the renovation a 350-liter aquarium would move into the room, and it was clear that there could no longer be any question of having a full-fledged table in this room. An old dream of a transformable table popped up in my head and everything started spinning.

Description of the master class

Selecting a table transformation mechanism.

I selected a suitable mechanism for transforming the table. First I chose how the table would be laid out, I really liked the Acrobat mechanism, but it is not supplied to Russia. Well, the only alternative available on the market was the mechanism of the following principle:

This mechanism is produced both in Russia and there are analogues from Europe and China. Supported the Russian manufacturer! The mechanism comes with springs or a gas lift, which are needed to help unfold/fold the table - for a softer ride. Without a doubt, I chose the option with a spring, because... The simpler the design, the more reliable it is. In addition, the spring is hidden in the mechanism body and is not visible when unfolding the table, unlike the gas lift which is too noticeable.

Designing a transformer table.

I made a layout of the future table in the PRO100 program. I used this program for the first time in my life, I figured it out in 1 evening. I made the layout in about 2 evenings. I took a picture from the Internet of a similar table as a standard and calculated the dimensions myself. It turned out to be nothing complicated. Many recommendations were sent in advance of the purchase of the mechanism, I was guided by them when calculating the sizes.

Cutting and edging laminated chipboard.

I ordered cutting of chipboard. In fact, there is an application for the PRO100 program that makes a cutting map, but since... I was too lazy to search and figure it out - so I made a cutting map manually and quite quickly.

There are also third-party elements on my map, because... I ordered another cabinet with the table. These extra elements are marked on the map with an X. The color of the laminated chipboard was wenge, the thickness, as recommended by the manufacturer of the transformation mechanism, was 22mm. The tabletop should be at least this thick. The mechanism is designed for such a load; the table body itself can be made from 16 laminated chipboards. But not everyone will order 2 sheets of different thicknesses with a large number of scraps) I ordered the edging immediately with a cut, the tabletop was 2mm PVC edge, the rest was standard melamine edge.

Initial fitting of parts.

I brought sawn and framed chipboard. I bought all the necessary hardware for assembly. I tried to fold the elements to exhale and make sure that I had not made a mistake with the sizes. Everything worked out, I was right with the sizes.

Assembling the table frame.

We assemble the table frame into confirmations using a special drill. We mark on dark-colored chipboards using stickers. This idea came suddenly after I tried to apply markings with a pencil on a dark laminated chipboard: nothing was visible and the pencil reflected and glare. The sticker solved the situation - the markings are accurate and there are no traces of glue left on the chipboard. In addition, the solution is quite cheap.

Well, the actual assembly of the table frame for confirmations:

We will fasten the mechanism through the end-to-end method, because The weight of the mechanism is impressive - 8 kg. every. There is no need to be afraid because... We have everything calculated and the overhead legs will hide all the technical holes and fastenings. We make markings for fastening the mechanism in the same way

We drill through holes for the bolts and then use a Fosner drill to prepare a place for the bolt heads to recess them.

Well, we bolt the mechanism. You shouldn’t be afraid of the number of bolts, they are all necessary, they fasten the walls of the table together even more firmly and make them self-supporting.

Assembling the transformer table legs.

Assembling the table legs. The legs must be very strong to support the weight of the table (which is approximately 45 kg) and the weight of the dishes on it. Therefore, it was decided to fasten the legs together with ties.

Screw the legs to the table. To do this, you need to very accurately mark the leg fastenings. To keep things simple, I drilled in place. We will install it on these metal bushings

For them, we drill holes in the legs according to the mark.

This is the position in which all the legs were screwed. The legs hide all the technical holes in the table frame.

Assembling the tabletop.

The tabletop must be assembled with particular precision, because the tabletop folding hinge must be strong and ensure smooth folding/unfolding of the tabletop. When I bought it, I doubted the hinges and for good reason. In principle they work, but it’s hard to hold the hinge in its sockets, and the screws that are supposed to do this don’t do the job. Therefore, I advise you to look at other hinges for the tabletop. Marking holes in countertops:

Assembled the countertops

Dear visitors to the site “Visiting Samodelkin,” from the material presented by the author, you will learn how you can independently make a transforming table for a gazebo from a 30x80 mm board.

I used different types of boards for the table: birch, pine, aspen, but it is best to take hard types of wood, such as birch, because the table and two benches are designed for 6 people, that is, the structure must withstand high loads.

The advantage of this table is that it compactly folds into a bench with a backrest and back into a table with two benches; it takes up little space when folded.

So, let's look at what exactly is needed to make a transforming table?

Materials

1. board 30x80 mm of different species (it is better to take birch boards) 2. metal corners 3. wood screws 4. wood glue or liquid nails 5. varnish 6. stain 7. M12 bolts 8. nut 9. washer 10. nails

Tools

1. hacksaw 2. screwdriver 3. drill 4. hammer 5. ruler 6. pencil 7. tape measure 8. protractor 9. angle 10. brush

Step-by-step instructions for creating a transforming table with your own hands.

After a long search on the Internet for a suitable drawing, I got to work, first of all I drew templates for the legs directly on the floor, you can also use a sheet of plywood.

Next, he saws the boards according to size; the author used different types of wood: aspen, pine, birch, but it is best to use hard wood. Please pay attention! There will be two benches, namely internal and external. First of all, the master makes an external bench; he showed us all the detailed dimensions directly in the photographs, which, mind you, is very convenient. The height of the legs is 440 mm, the width of the legs at the bottom is 400 mm - this is very good for the stability of the bench. Attention important point!

The length of the internal crossbar is 150 mm, we remind you once again

that the crossbar is located inside.

The length of the outer bench is 1380 mm; before direct assembly, all workpieces should be thoroughly sanded and be sure to chamfer so that the surface is smooth, even, as they say, “Without a hitch.”

The bench turns out to be simple, and the master makes the fastening using wood screws, wood glue and, for greater reliability, adds metal corners, since the structure must be extremely strong.

So, let's move on) Now you need to assemble the Inner Bench

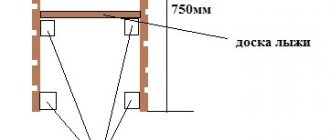

Note! The height of the legs on both benches should be strictly the same, but the crossbar that fastens the legs is moved outside and its length is accordingly increased to 400 mm, the length of the top bar is 350 mm where at a distance of 40 mm from the edge a hole is drilled for an M12 bolt and drilled out to recess the bolt head into cavity of the board so that nothing protrudes. The author indicated all the necessary dimensions directly in the photographs.

The length of the bench is 1440 mm, but in each individual case the dimensions may vary, because everyone makes it for themselves, but as a standard we use the dimensions presented by the master.

Holes are drilled in the top bar.

After both benches are ready, you need to try them on and one should fit into the other with a small gap (see photo)

That is, two benches when folded should create one whole.

This is exactly what should happen in the end.

We've sorted out the benches a little, now let's move on to considering the author's further actions, namely the manufacture of brackets from timber. The angle of connection of two bars should be about 100-105 0 (see photo) where beam “A” is responsible for the width of the tabletop, and beam “B” is the height from the top of the bench to the tabletop.

A hole is drilled in timber “B” for an M12 bolt and drilled out to recess the head into the cavity of the wood.

After that, the resulting brackets should be connected to the inner bench; we place a washer at the connection point so that there is no mating.

The head of the bolt is recessed into the drilled hole.

The same is true on the opposite side.

In general, 2 brackets are fixed in this way, which are responsible for the height and width of the tabletop.

Then you should align both brackets evenly.

And now the fun begins)) you need to connect the tabletop with the outer bench, this is done using a straight strip, its dimensions are indicated in the photo.

These strips need to be made in 2 pieces, the author struggled for a long time to get the exact size during the fitting process, so in each individual case there may be errors. To begin with, the master drove nails along the edges of the planks and made a mark with them, that is, he drove a nail so that it stuck out a little on the other side and made a mark, and then drilled a hole for an M12 bolt

Everything must first be carefully adjusted, and then drilled calmly, as they say, “Measure twice, cut once.”

It is imperative to make a limiter on this bar so that your tabletop does not move apart; for example, the author’s one looks like this.

That is, when unfolded, it will fix the tabletop in a level position and will not allow further movement.

As you can see, everything is quite simple, a piece of board is cut at a certain angle and attached to the plank using 2 self-tapping screws.

For complete symmetry, everything is done the same on the second bar.

I have long wanted to make with my own hands both a coffee table and a transformable dining table. The idea of creating such furniture is that the assembled table can instantly turn into a full-fledged kitchen or dining table. I decided to make my own transforming coffee table from wood. As a project, using my experience in drawing, I drew a diagram for assembling furniture. Before starting work, I prepared the appropriate tools and purchased the necessary materials.

Assembly order

Following the drawings and diagrams, prepare all parts of the frame, table and bed. Only after this is the main frame assembled, attaching the transformation mechanism to it. Be extremely careful and careful.

For convenience, it is better to carry out the assembly together. At the very least, you will definitely need an assistant to fix the power traction units with bushings (this process will require significant physical effort).

Making a transforming table is a great alternative to bulky furniture in small apartments.

Economical, functional and comfortable, they free up space for various things (books, computer, etc.) and space for outdoor games in the children's room.

The range of transformable tables is so wide that it can satisfy the most demanding taste.

Materials

I bought all the necessary materials at a construction supermarket. I had some in stock. The list of all materials turned out like this:

- edged pine board 4100 x 400 x 25 mm;

- screws 20 mm – 40 pcs.;

- screws 50 mm, 70 mm – 10 pcs.;

- metal corners 40 x 40 mm – 4 pcs.;

- stain 0.5 l.;

- furniture varnish PF 170 – 0.5 l.;

- wood glue “Stolyar” - 125 g;

- wooden dowels 30 mm - 24 pcs.;

- round self-adhesives – 8 pcs.;

- piano hinge 400 mm – 4 pcs.

Step-by-step instructions on how to assemble a coffee table - transformer

- I sawed a board 400 x 25 mm, 4100 mm long, with a jigsaw into pieces:

- table top and sides 800 x 400 mm – 4 pcs.;

- legs 900 x 50 mm – 4 pcs.;

- 2 crossbars 700 x 50 mm and 650 x 50 mm;

- triangular struts with sides 5, 10 and 11 cm – 4 pcs.

- I cleaned the entire surface of the wood with an emery wheel and a sander.

- The boards were covered with stain.

- Then the wood was coated with furniture varnish in two layers.

- I cut the ends of the table top and the adjacent ends of the other two boards with a jigsaw at an angle of 45 0.

- At the ends of one side of two 80 x 40 cm boards, I drilled mounting holes for wooden dowels with a drill.

- I smeared the dowels and ends of the adjacent sides of the two boards with wood glue and connected them into one tabletop.

- He tied the tabletop with straps and left it alone for a day.

- A day later, I removed the tension straps from the tabletop.

- I installed a folding mechanism in the form of piano hinges, connecting the side boards with the tabletop.

- I attached legs to the sides of the table with steel corners, the ends of which were cut at an angle with a jigsaw. The fastening was done with screws using a screwdriver.

- I installed struts, connecting the tabletop and legs with them. To do this, I made holes in the adjacent sides of the parts. I inserted dowels into them, coated with wood glue.

- The legs on each side were connected by crossbars. I secured the crossbars with screws using a screwdriver so that when folding the table they would not interfere with each other.

- The screw holes in the legs where the crossbars are secured were covered with self-adhesive tape.

- I glued pieces of felt to the ends of the sidewalls, which become supports when folding the table. This will prevent abrasion of the surface of the supporting part of the sidewalls.

- I also glued felt nickels to the supporting surfaces of the legs. The table will not scratch the floor with its legs, and it can be easily moved on any floor covering.

- He opened the small table and set it on its legs. It turned out to be a comfortable dining table, which I placed in the living room.

After I assembled the transforming table with my own hands, I summed up how much money I spent and how long it took to assemble the furniture.

What is necessary

Necessary tools for furniture assembly

To successfully assemble the transformer you will need:

- Phillips screwdriver or screwdriver with attachments;

- furniture hammer;

- fasteners and accessories included in the delivery kit.

Detailing the table frame and its legs

Box with fittings and fastenings

Despite the many offers on the furniture market, for most manufacturers the process consists of the following steps:

Housing assembly

Assembling the corner legs of our table

All legs for the transforming table are assembled

Corner legs of two halves are connected with screws or eccentrics. In the same way, a body is assembled from long and short drawers.

Housing assembly diagram

Detailed case assembly process

Screw the legs to the body according to the instructions

IMPORTANT! Special holes are made on the legs and drawers for simultaneous installation of the lift and screed of the entire structure. Check after assembly if they match.

Assembled base with legs

Nail the plastic foot pads to the bottom ends of the legs. At the upper ends of the drawers, install shock absorbers to soften the impact of the tabletop when folding it.

We nail heel pads to the legs

Installation of the lifting mechanism

Installation diagram of the lifting mechanism

Bring the lift into working position. For this:

- hook the spring with one end to the hole inside the lift;

- insert a pin threaded into the second end of the spring into the groove located on the opposite side;

Spring in working order, attached to the mechanism

Fixed springs for operation of the transforming table mechanism

The mechanism is in a calm, unexpanded state

IMPORTANT! The legs of the holders designed for a folding tabletop are higher than those made for the underframe.

Mechanism for bringing the table to the upper position

Installation of countertops and underframes

Mounting a smaller part of the countertop

Installing the base for a large part of the tabletop

Screw the bottom flap of the book-table top and the base to the holder platforms. Install shock absorbers on the outside of the tabletop to absorb shock when unfolding the tabletop. Using an outside-in motion, fold the lift legs into the box. It will be covered by the bottom of the tabletop.

Fix the upper movable part of the tabletop

Place the second half on top so that the end holes for the hidden hinges are on one side, and their center-to-center distance is minimal (about 14 mm). Carefully insert the hinges and secure with screws.

Hidden hinges to secure the table when assembled

The table you assemble will last a long time. Do not forget to tighten its fastening joints once a year, clean the surface with a dry soft cloth or a special furniture polish.

Coffee version or folded table

The process of transforming a table from a coffee table to a table for receiving guests

Dining option or unfolded table

Cost of materials

- edged pine board 0.04 m 3 x 4200 rub. = 170 rub.;

- screws 2 cm – 40 pcs. in stock;

- screws 50 mm, 70 mm – 10 pcs. in stock;

- metal corners 4 x 4 cm – 4 pcs. x 2.5 rub. = 10 rub.;

- stain 0.5 l. = 100 rub.;

- furniture varnish PF 170 – 0.5 l. = 50 rub.;

- wood glue “Stolyar” - 125 g = 70 rubles;

- wooden dowels 30 mm - 24 pcs. in stock;

- round self-adhesives – 8 pcs. in stock;

- piano hinge – 400 mm – 4 pcs. = 4 x 44 rub. = 176 rub.

Total: 576 rub.

Labor costs

The time spent on assembling the transforming table was reflected in tabular form.

This is pure time spent only on performing individual operations. Taking into account technological breaks and rest, I assembled the table in 2 days.

A table of this design, when assembled, can serve as a convenient surface on which newspapers and magazines will be placed. The table is suitable for serving breakfast or dinner. When folded, the structure occupies a minimum of usable space. If necessary, the transformer can be “turned” into a fairly spacious dining table.

Folding furniture is attractive for use in the country, in summer pavilions and on picnics. The table easily fits in the trunk of a car.

An elementary sense of common sense prompts you to assemble a transforming table with your own hands - cost savings in this case will range from 50 to 75%, depending on the model and materials. It may not be possible to make an extendable table without significant loss of time if this is your first experience in making furniture. However, the time spent is compensated by the acquired skills, which allow further projects to be carried out much faster. After all, not a single home master picks up an instrument just once: in the living room, bedroom, hallway there is always a place to apply his strength and creative imagination.

Advantages of a transformer for the living room

Modern lifestyle values the quality and functionality of the things with which we fill the space of our home. Nowadays, it is very popular to have as much free space in the apartment as possible, and certainly in the living room, where the whole family and invited guests gather for the holidays.

A transformer for the living room will satisfy all these requirements.

If for some reason you have not yet come across a similar option, then you just have to look at pictures of various transforming tables and you will immediately and immediately want to become the owner of such a miracle of invention.

Advantages of this type:

- Significant space savings;

- Ease of use;

- Capacity;

- Saving money;

- Durability.

Transformers come in a variety of shapes and sizes. They can be: round and oval, large and small, with a variety of rotating mechanisms, with height adjustment. The designers' ideas are amazing; the table can be transformed into a bed, armchair, or sofa. As the names suggest, these are complex structures that allow you to transform the table into a comfortable place for sleeping and relaxing.

Folding book table

In many families, a large dining table is not needed all year round. However, its presence can help out if guests arrive. The sliding mechanism is ideally suited for these purposes; a modest wooden table equipped with it stands discreetly in the corner, performing auxiliary functions. But when his time comes, he stands in the center of the apartment.

It is proposed to make a frame furniture mechanism with lowering halves of the lid. Materials you will need:

- planed bars 20x50 mm;

- plywood or thin 10 mm planks (for boxes);

- furniture board: chipboard, laminated chipboard or MDF (on the lid).

Fig.1. Drawings of a folding table-book: 1 – driving frame; 2 – rotating frame; 3- folding plane; 4 – drawer; 5 – assembly of the side part of the main frame (option B); 6 – medium narrow chipboard tabletop option B

Fig.2. Table assembly diagram: 2 – elements of the rotating frame; 3- folding plane; 4 – drawer; 5 – driving frame

Mechanism for assembling the table-book:

- The table legs are sawn off to the required length.

- Markings are applied to them.

- According to the markings, grooves are hollowed out for the longitudinal drawers (transverse slats connecting the table legs).

Note! Grooves for the lower slats can be made at an arbitrary height, and when hollowing out the upper slats, take into account the height of the drawer.

- The longitudinal drawers are sawed off to length.

- Single spikes are filed down at their ends.

- Glue the side frames (2 pieces), after checking the accuracy of the assembly with a square.

- While the side frames are drying, make 2 supports for the side covers of the table. They are also of frame construction (in Fig. 1 and 2 - No. 5).

Installation of a table-book

The length of the support legs corresponds to the height of the table legs. The size of the other vertical post is equivalent to the distance between the outer edges of the longitudinal frames. And in order for the supporting support in the folded position not to look beyond the table, the width of the support should be equal to half the length of the table sides.

Mechanism for assembling the table-book (continued):

- On the bars intended for support, it’s time to make single through and blind tenon joints.

- The bars are connected with glue.

- In the dried sidewalls, saw down and select recesses for attaching short transverse drawers (No. 2 in the diagram).

- The sides with these short drawers are connected with glue and screws.

- Guide rails are attached to the inside of the upper longitudinal drawers to move the drawers (No. 4 in the diagram).

- The side walls of the drawers (cabinets) are made of plywood or thin 10 mm boards.

- The front wall of the cabinet should be made of a thicker board.

- Quarters are cut along the edges of these boards to attach the sides of the box.

- All elements of the cabinets are held together with glue and screws.

- The bottom of the cabinets (drawers) is cut from thin plywood or fiberboard.

- Note! A special feature of the design is that the front wall of the drawer extends inside the legs. This means that the front plane of the wall and the edges of the legs are flush. And in order to achieve this, clamps are attached to the guide rails and upper longitudinal drawers, which do not allow the drawer to move further than necessary (No. 3 in the diagram).

- Table tops are cut from chipboard, laminated chipboard or MDF. Begin work by marking and cutting out the middle cover.

- Note! The edges of the middle cover above the table structure will protrude 20-25 mm. This will allow the support support to be hidden under the lowered half of the lid.

- The middle cover is secured with four metal corners (No. 3 in the diagram), screwed with screws from the inside of the upper transverse frames.

- The side covers are attached to the middle one with a piano loop. It is screwed on from the bottom with screws.

- Note! If you turn the furniture structure over, connect all the lids and only then start tightening the hinges, it will be more convenient to work.

Was regular - became folding

To assemble a transforming table with your own hands, you don’t have to start everything from the very beginning. You can convert an existing wooden single- or double-pedestal table into a sliding furniture mechanism. The design solution in both cases is not particularly different - the tables are equipped with a retractable element.

Fig.3. The mechanism for converting a two-pedestal table into a sliding one is represented by the front panel of the top drawer (1); persistent chipboard board (2); loops (3); horizontal chipboard board (4); screws (5)

To modernize a two-pedestal table, as the drawings show, it is necessary to get rid of the top drawer of the right cabinet. If, due to the layout of the living room, it is more convenient for you to part with the pull-out cabinet on the left cabinet, carry out the project in a mirror manner. This issue is not fundamental; the selected desk drawer must be completely disassembled. Only its front side with the handle should remain.

Another board is attached to this board with screws (5) at the end, the dimensions of which coincide with the dimensions of the box that was previously there. Loops (3) are screwed from below, on which the thrust board (2) is fixed.

Board No. 2, when folded, should be in close contact with board No. 4 so that entering the space freed from the box is problem-free. When extended, board No. 4 will serve as an additional table, and board No. 2 will serve as a support for it. To avoid distortions, this plane should be tilted completely 90°.

Differences in retrofitting a single-pedestal table

A table with one cabinet, after modernization, will increase its area much more than a two-pedestal one. In addition, its disassembled geometry will be different from the layout of a two-pedestal structure.

Fig.4. The mechanism for converting a single-pedestal table into an extendable one is represented by a horizontal cutout (1); desk drawers (2); retractable board (3); thrust board (4); wheels of the thrust board (5); squares (6); side wall of the table (7); additional slats (position

As in the first case, you will have to remove the drawers. But this time it will not be cabinets located in the cabinet, but drawers located at the top of the table itself. Both boxes should be removed, and a horizontal cut should be made on the left side of the box (1). The width of the completed opening should be equal to the thickness of the selected sliding board (3), which in the near future will become the plane of the elongated table.

The mechanism for smooth sliding of the retractable board in the formed internal niche of the table will be provided by additional slats (8), installed along the direction of its movement. To prevent the board from falling out from the end that goes into the furniture, you should make 2 stoppers. From the side of the second end, a thrust board (4) on wheels (5) is attached to the sliding board at a 90° angle with squares (6). Board No. 4 is rigidly attached to board No. 3, and when assembled it fits tightly to the side wall of the table (7). In the place where the drawers (2) were previously located, a decorative plate is installed, after which the sliding furniture mechanism can be considered ready for use.

It is understood that the dimensions of your table may differ from what our drawings show. However, the measurements of all elements and the mechanism for re-equipping the table, presented in Fig. 3 and 4 can be taken as a basis when performing conversions.

Original and simple coffee tables

With unlimited imagination, you can make very beautiful and original tables. For example, from wooden boxes! By connecting four drawers in a circle with ordinary nails, installing them on a sheet of plywood with wheels and painting them, you can radically transform the interior.

For such a coffee table, 4 pieces of 45 cm each and 26 pieces of 15 cm each were required. An excellent solution for a high-tech interior.

A simple way to make a beautiful wooden coffee table is explained in detail in the video:

A transformable coffee table is an excellent solution for small apartments that have little space for a variety of pieces of furniture. This table folds and unfolds depending on the needs of the owners. When folded it is a small coffee table, and when unfolded it is a table for guests. This design makes the table multifunctional and practical.

Drawing of a transforming table.

Even a person who has never made furniture before can make a transforming table with their own hands. All you need is desire and patience.

Two-level table

The proposed wooden table can be used as a coffee table all year round. However, if necessary, it easily and elegantly turns into a living room decoration - a large dining table. Drawings of this product in different sources may differ slightly, we offer optimal sizes. Judge for yourself, when folded, this is a wonderful coffee table; it reaches a height of 752 mm. But by lifting the top of the structure until the supporting pedestals are disconnected, turning the lid 90° and sliding the pedestal (3) into the pedestal (6), we get a high dining table.

Fig.5. Coffee-dining table for the living room. Consists of table top (1); base plate (2); cabinets (3) attached to tabletop 1; support rail (4) of cabinet 3; stiffener beam (5); cabinets (6) attached to the base plate 2; support rail (7) cabinet 6

The design of the coffee and dining table is panel, all elements are attached with dowels and glue. Making this item for the living room interior will require precise measurements; it is especially important to maintain the dimensions of the cabinets. In addition, you should pay attention to the strength of the connection of the slats (7) on which the cabinet (3) rests.

One of the greatest inventions in home improvement is the folding table. Lightweight and compact, it is perfect as a picnic table or camping table. This is a great gift idea for friends or neighbors. It’s easier to buy such a transformable table in a store to save time and effort. But by making it yourself, you can not only save money, but also develop its design as you wish.

Various options are possible: wooden, plastic, aluminum transforming tables.

With just three simple materials, every DIYer can make his own folding furniture in the shape or form he likes.

By spending time productively and visiting local lumber and tool stores, you can select and purchase ready-made materials. In addition, you can simply walk around in the yard around your own house, perhaps you will also be able to find something there that can be used: all kinds of remnants of wood or nails left over from last year’s renovation or something else. All this can be used in a new project.

How to install a base

After assembling the tabletop, you can proceed to assembling the underframe. As the name suggests, these units are hidden under the tabletop when the table is assembled. Therefore, it will be convenient to assemble the underframe when the product is unfolded. In this case, it is necessary to assemble all its components separately and then attach them to the body.

After the assembly is completed, it is important to conduct a final check of its functionality, so as not to be embarrassed later when displaying the furniture. All mechanisms should work without much stress and quite gently.

When assembling, it is important to remember safety precautions. Especially when working with sharp drills, as well as when checking the opening and closing mechanism. Since hands can easily get into the space of the mechanism itself.

If you purchased a transformer, carefully study the instructions for assembling it. There is nothing complicated about it. And you will definitely end up with an attractive piece of furniture.

In many apartments, the living space is not very large, so residents have to select furniture so that the arrangement is cozy, but at the same time compact. In such cases, folding furniture comes to the rescue, helping to save space without depriving residents of necessary household items. A transforming table is a representative of such furniture.

Transformable tables are used in kitchens, living rooms, and bedrooms. This item is made completely differently, depending on what functions will be assigned to it. Such tables are also called folding tables. Tables are classified according to their functions:

- coffee-dining;

- coffee tables (as a workplace);

- tables as storage systems.

The first option is the most relevant. As a rule, such tables are bought by a young family shortly after the wedding and the number of guests gathering at this table only grows over the years, but the area of the apartment does not. This coffee-dining option serves as a stand on ordinary days and does not take up much space, but on weekends or holidays it turns into a real dining table. It doesn't take too much effort to seat 5-7 people. In addition, such a table is the most ergonomic for a studio apartment, where all living space is combined.

To create a coffee table as a workplace, other types of tabletops are used. For these purposes, it is not at all necessary that it be completely disassembled or change its shape. This table option can be quickly and easily converted into a desk and adjusted to the required height. As an addition, the table is equipped with drawers for more convenient storage of office supplies. The table can be given several positions due to the type of fasteners used in each specific case. Where continuously adjustable mechanisms are used, operation is much simpler. With such an item, you can create a workplace even in an apartment where there is a lot of furniture and there is no room for a large desktop.

Tables that are used as a storage system are a fairly simple design. They consist of drawers and a tabletop. Such a table unfolds by spinning it around its axis.

Materials and tools

For one small portable wooden table you will need:

- Approximately 1-1/2 inch wood board for table top. You can also use a thicker board or sheet of plywood. It all depends on the expected load on the table for which it is intended. It can be any wood: pine, cedar, oak, etc., the main thing is that it must lie long enough to dry. You can also use plastic as a tabletop.

- A thin piece of plywood for the rim of the table top or any other material that matches the type and method of processing with the table top.

- 20*45 block for making table legs. You can also use a metal tube or corner as legs.

- Wooden parts for support rails according to the selected table dimensions.

- Electric drill and drill set.

- Screwdrivers, wrenches (including socket wrenches).

- Saw (manual or electric).

- Brass hinges (long, garage type).

- A set of screws, nails and other fasteners that may be needed. In this case, be sure to take into account the conditions in which the table will be used: for outdoor use, galvanized metal products should be used.

- For finishing: sandpaper, paint or varnish, stain, brushes.

- Preparation of the drawing.

First, you need to “sketch” a drawing of the proposed table in order to decide in advance on its design and correctly calculate the dimensions. This table will have few details:

- tabletop (one, two or three parts);

- frame with stiffening ribs;

- legs.

It will be easier to keep to scale and change dimensions if necessary if you make such drawings on graph paper. You can download a copy of the sketch of the table model you like from the Internet. But since, despite all the efforts made by the authors of DIY sites, there is a possibility of errors in the dimensions of the drawing, it is worth making sure they are correct by checking the calculated values.

Return to contents