How to make MDF moisture resistant

Medium-density fiberboard, or MDF, is a versatile and inexpensive material that has many uses.

MDF is used to produce shelving, furniture of various qualities and moldings. MDF is made from recycled wood and resin pressed at high temperatures. The finishing coating for MDF can be PVC film, veneer and varnish. MDF parts are very durable and easy to work with; delamination and fractures are unlikely with this material. However, if you plan to use this material in places with high humidity, you should think about protecting the MDF from moisture, otherwise the MDF will begin to deteriorate from exposure to moisture and dampness.

Do-it-yourself interior wall decoration at the dacha

In creating a cozy atmosphere in a country house, the decoration of the walls in the country house plays a significant role. Materials of varying costs can be used as final decorative finishing.

In the case where the work will be carried out in a seasonal house in which there is no constant heating, preference is given to budget options.

It will be useful: Interesting decoration of the balcony

When purchasing a finishing material, it is important to understand whether it can be used in conditions of high humidity, which are inevitable in unheated rooms.

Moisture-resistant MDF

While MDF should not be used for exterior applications or in areas where the material will be regularly exposed to moisture, there are two approaches to waterproofing fiberboard: you can use moisture-resistant MDF outright, or you can make your MDF moisture-resistant yourself.

It's worth noting that whichever method you use, MDF will only be moisture resistant, not waterproof, and in no way waterproof. It will also swell and deteriorate upon direct contact with water.

The first, and also the simplest approach, is to purchase moisture-resistant MDF, which is designed for areas where moisture is a problem. Compared to regular MDF, moisture-resistant MDF is still easy to sand, paint, and veneer can be placed on it well, but it is made using moisture-resistant resin. Moisture-resistant MDF is great for kitchens, bathrooms, boiler rooms and laundry rooms. Therefore, this type of MDF costs a little more, but its qualities are worth the overpayment.

Kinds

Today, the domestic market offers a wide variety of all kinds of plastic products. Wall panels have several different variations for use in the bathroom. In fact, in terms of performance they are at the same level, however, in terms of functionality and appearance they differ quite sharply.

Leafy

Sheet models are very large elements. They differ from other brothers, first of all, in their size, but at the same time they are very easy to install. They are usually used with a pattern or image already applied. Sheet products are a high quality material that resists high levels of humidity and temperature changes.

Sheet panels

Typically, sheet panels are used for installation in the most difficult, from an operational point of view, areas. Often this is either a kitchen area or a bathroom, which allows the data in the room to be reliably protected. The main material used for the production of sheet products is fiberboard raw material. Eucalyptus additives containing natural resins, essential oils and other natural components are specially added to it.

This, together with protective impregnation, makes it possible to give sheet panels high strength and fire resistance. In addition, the production of sheet products from PVC material is allowed. In this case, it is a special sheet of medium-sized plastic. The resulting model is very convenient for transportation and installation. During installation, a very small number of joints and seams are obtained. This has a positive effect not only on the appearance of the shower, but also on its performance.

In addition, wall panels are treated with protective impregnations that protect them from the effects of aggressive environments that are formed when using cleaning products. It is also worth noting that special impregnations protect the material from additional load and scratches on the surface of the sheet. The service life of this product can vary from 10 to 15 years.

Rack and pinion

The next type of wall panels used indoors is slatted. These products are distinguished by high moisture-resistant properties in comparison with wooden or plastic lining. The domestic market offers a fairly extensive range of rack and pinion models. You can easily choose a wide variety of colors and shades of panels. This allows you to add a little originality and aesthetics to even a nondescript shower room.

Slatted panels

This material will fit perfectly into a room that is not distinguished by its large dimensions. Slatted products will create a special coziness and feeling of comfort in the space, by the way, visually enlarging it a little. Due to the visual effect, the height of the ceilings increases, and if you choose interesting patterns, you can get an original shower room. The structure is installed using special glue, as well as staples and screws.

Tiled

Finishing with panels is carried out differently depending on the models. For example, tile panels are laid in a checkerboard pattern. These panels are made from the most modern materials. The most commonly used raw materials are plastic and also have a square shape. They are laid on the surface of the wall in the shower room. In addition, these products successfully replace mosaic coatings, natural stone, wood, decorative plaster, and other materials.

Tile panels

Before laying the frame, it is necessary to thoroughly treat the surface. It should be well prepared for the installation of tile products, otherwise the fastenings will begin to loosen over time. This will lead to deformation of the structure, as well as the creation of favorable conditions for the proliferation of microorganisms.

How to make MDF moisture resistant yourself

Using varnish, moisture-resistant paint or a quality wood sealant, you can protect your MDF product from contact with water.

Do not use water-based varnishes as they may not adhere to the MDF surface.

1) You should start with a primer insulator specifically designed for MDF. After application, the primer needs 6 hours to dry.

2) After the insulating primer has dried, apply the main primer.

3) Apply a final coat of varnish. It takes at least 3 days for the MDF to dry and become moisture resistant

Don't forget to cover the edges of the MDF with an edge to ensure all-round protection of the material.

Which kitchen façade should you choose from the huge variety of materials on the market today? This issue worries not only citizens who are furnishing their homes, but also furniture manufacturers. After all, the competitiveness of products and the success of the business as a whole often depend on how accurate the “hit on target” is when choosing facades for furniture production.

Egger laminated chipboard is a material of European quality, suitable for the production of various types of furniture, finishing living and working spaces. You can buy Egger laminated chipboard at retail in Moscow from our company.

MDF (Medium-Density Fiberboard) is a medium-density fiberboard. The process of their production is in many ways similar to the process of producing chipboard: sawdust in both cases is pressed or dried. However, there are a number of technological features due to which MDF boards have much higher consumer properties.

Source: www.ldsp-shop.ru

Installation Features

In order to attach models of various sizes to bathroom walls, no special skills or abilities are required. By and large, the installation of wall MDF is very simple, but it has its own nuances. Many panels are attached to the sheathing, which greatly simplifies the installation process. In addition, if the walls of the shower room are smooth, then finishing can be done without prior preparation.

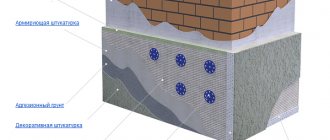

Installation on the sheathing

However, if there are defects in the wall surface, they must be corrected. The wall should be primed, plastered, or gypsum board blocks used. The latter option allows you not only to level the surface, but also to create a new one. After preparation, you need to take measurements of the room. In addition, it is necessary to let the moisture-resistant panels sit for several days in the bathroom. This will allow them to acclimatize and get used to new conditions.

Leveling the wall with plasterboard

After which they will acquire qualities that correspond to the temperature regime of the shower room, as well as the level of humidity. It is best to attach sheet panels of various sizes to the wall using a special frame - sheathing. This makes it possible to connect communications, for example, wiring for lighting. This method is suitable for coatings with small defects that need to be hidden. Wall MDF is mounted using self-tapping screws, special brackets, clips or nails.

Installation is carried out starting from the corner of the moisture-resistant product. It is worth knowing that a smaller hole will be better in terms of subsequent operation. In addition, if you get tired of the lathing option, then after some time you can remove it without unnecessary problems. This is suitable for people who like frequent changes of interior style in the bathroom. It is worth noting separately that the installation of wall panels can be carried out both on a frame with a metal base, and on a structure with another material.

Moisture resistance of MDF

Waterproof MDF, unlike regular MDF, is denser. As a result, the slab does not swell, and its surface is not destroyed by condensation. Produced by dry pressing under high pressure, MDF is not susceptible to moisture, they are characterized by high strength and hardness, and at the same time, ductility during processing. Such properties allow them to be used as wall panels, the basis of the components of a kitchen set, kitchen facades, and bathroom furniture.

Moisture resistance is achieved by using a special adhesive composition, which consists of MUF (melamine ureum formaldehyde - melamine-urea-formaldehyde) components, characterized by an effective curing system.

The slabs obtained in this way are used in wet rooms, exclusively inside the building, and can withstand accidental contact with water. Such slabs are lined with melamine, laminated, PVC film, and also covered with a variety of finishing materials. This material is sawed and milled using conventional machines.

Moisture-resistant MDF boards are used for:

- interior design

- as furniture components

- to create partitions

- in areas that need protection from moisture

- for creating exhibition stands, kiosks

- as packaging material

- It is used to make baseboards and beams, as well as window sills.

The advantages of moisture-resistant MDF include:

- aesthetics

- environmental and hygienic impeccability

- hard surface

- no swelling or warping

- ease of machining

- high wear resistance

- light weight compared to wood.

Chipboard: characteristics, pros and cons

The most popular material for the production of cheap office furniture, interior decoration, and interior partitions. In general, the scope of use of chipboard coincides with MDF. What is the difference between MDF and chipboard?

Thus, to create chipboards, they do not take whole logs or woodworking waste, but wood chips, shavings, and sawdust from low-value tree species (both coniferous and non-coniferous). These shavings and sawdust are hot-pressed and bonded together using formaldehyde or other synthetic resins. These resins are a carcinogenic substance, therefore, depending on the level of their content in the chipboard, their class (and cost) will be determined:

— Chipboard class E1

– lower level of formaldehyde emission, that is, carcinogens are not so actively released into the indoor air;

— Chipboard class E2

– high level of emissions into indoor air, prohibited for the production of children's furniture.

By the way, in European countries the production of chipboards of classes E1 and E2 has recently been prohibited; only chipboards of the “Super E” class are produced. As we can see, the difference between chipboard and MDF is also that carcinogenic resins are not used in the production of MDF, unlike chipboard. A very compelling argument.

Chipboard: advantages

— low cost

Good technical characteristics

– chipboard slabs can be sawed, glued, painted

High thermal insulation and sound insulation

properties

— biologically resistant material

, not exposed to aggressive environments, and with the introduction of special substances it can be moisture-resistant and fire-resistant (but it must be admitted that chipboards are rarely provided with such qualities; almost all chipboards produced by the industry are “ordinary”).

— very hard material

. Unlike MFD, chipboard will not be damaged by the fall of a heavy object - there will be no dents left on it

Quite decent appearance

, especially when it comes to laminated chipboard. A comparison of laminated chipboard and MDF in terms of decorativeness would be very appropriate: wood-like coatings, multi-colored coatings. Laminated chipboard is resistant to both mechanical and thermal influences. By the way, laminated and laminated chipboard look almost the same, but the former will last much less.

Cons of chipboard

The biggest difference between chipboard and MDF is the impact on health

. Environmentally unsafe chipboards contain carcinogens that affect your health. Yes, there are boards with very low formaldehyde resin emissions. But the phrase “this table is a little carcinogenic” in relation to your children sounds like blasphemy.

— does not hold fasteners well

. Once a self-tapping screw falls out, it will fall out all the time.

— impossibility of fine processing

(shaped parts, deep milling).

Moisture-resistant MDF panels

These panels are ideal for use in the bath and kitchen. For other rooms, such material is rarely used. In appearance, the panels are very similar to tiles.

The panels are made from moisture-resistant MDF, which is treated with a special compound. Moisture-resistant MDF panels are created on modern equipment using the latest technologies.

The advantages of such moisture-resistant wall panels include:

- aesthetics

- you can hide various flaws, for example, unevenness

- ease of installation and choice of several installation methods. Installation methods depend on the layout of the room, the presence of partitions, as well as the raw materials from which they are created

- ease of use. Such panels are easy to cut; there is no need to buy special tools. Due to its large size, installation is very quick

- they are environmentally friendly, durable, practical

- when using glossy panels, the room visually expands

- reasonable cost

- you can mount the panels in any direction - along or across the wall, and even diagonally

- after installation, an under-panel space remains, which can be used as a place for hidden wiring, and as additional insulation.

This material can be installed on a wooden or metal frame, which is a more labor-intensive option. Installation using “liquid nails” is also possible. This option is used if the base is smooth and even. The widest range of colors and textures that imitate almost any material makes it possible to select finishing materials that fit perfectly into any interior.

Today you can buy three types of moisture-resistant panels in stores:

- Slat panels are very similar to ordinary finishing lining. The material is fastened using special brackets (clasps). Such panels allow you to visually solve problems with low ceilings by decorating the walls with vertical panels.

- Tile panels are made in the form of squares or rectangles. The main tasks of this material are: finishing the ceiling, creating unique ornaments and patterns, creating a design by combining various textures and shades. Such slabs can be very similar to tiles, mosaics, marble, and much more.

- Sheet moisture-resistant MDF panels are produced in a fairly large format, which affects the installation speed. This creates the smallest number of joints. Sheets may have an ornament or design. The variety is very wide.

It is worth noting that moisture-resistant MDF panels are completely natural and environmentally friendly, because special urea resins are used for their production, which do not cause harm to human health.

Source: wood-prom.ru

MDF panels union

Decorative film is a waterproof material, i.e. it can be used in rooms with high humidity. It is also not afraid of high temperatures and can withstand up to 80 0C. Today there are more than 500 colors of self-adhesive film: marble and stone, velor and velvet, wood, stained glass and mirror. Countless patterns, structures, colors and clever combinations, including a special range of borders, open up unlimited possibilities for designers. Single-color self-adhesive films in rich colors, matte and glossy, with ornaments, patterns and structures, with simple elegance or with a fashionable metallic sheen, self-adhesive films for purely decorative finishing or for more practical purposes, for emphasizing individual design details or for completely updating the furnishings - self-adhesive films are very widely used everywhere. For example, updating furniture with self-adhesive film is much more profitable than buying new one. Also, if you need to protect windows from prying eyes without using curtains, transparent stained glass self-adhesive film is the best solution.

Self-adhesive films with wood decor cover about 70 different designs, from classic oak and pine, tropical woods, beech and to whimsical fantasy designs. The palette of patterned films ranges from clear embossed films and clear patterned glass for window decoration to fantastic patterns and children's motifs, while special tile, marble and relief patterns allow you to cheaply and quickly reproduce natural materials. There is also a self-adhesive film, which, thanks to its special seal, is designed specifically for surfaces subject to heavy loads.

General recommendations for working with self-adhesive film:

The base that needs to be covered with self-adhesive film must be clean, smooth, free of grease and dust. The ideal base is varnished boards, free of dust.

Boards without varnish are primed using polyester or primer varnish, and, if necessary, using methyl wallpaper glue.

Rough, porous surfaces (wood, plywood, chipboard, fabric, cork, ceramic tiles, plaster, plaster, etc.) must be dry and dust-free. If necessary, the surface can be treated with a primer. Uneven or cracked substrates are leveled using putty and sanded. Then they need to be cleaned and coated with a primer (acrylic based) - this is necessary to ensure maximum adhesion strength of the self-adhesive film.

It will be useful: How to strengthen the door threshold?

Slicing. Cutting is facilitated by a centimeter grid (scale), which is printed on the back paper side of the self-adhesive film. When cutting long, even pieces, it is recommended to cut with a knife along a ruler. It is recommended to cut with a margin of 2-3 cm. If the self-adhesive film has a repeat pattern, then you need to cut along the front side. Self-adhesive film with a tile pattern is cut along the seams of the tiles.

Sticker. On the reverse side of the self-adhesive film, on paper and in pictures, there is a manual for working with the self-adhesive film. You should separate the paper from the self-adhesive film by approximately 5 cm, then apply the self-adhesive film to the surface and glue the separated edge. After this, you should slowly and evenly pull the paper off the remaining part of the self-adhesive film with one hand.

Use your other hand to smooth out the self-adhesive film with a soft towel. It is necessary to smooth from the center to the edges - this can avoid the formation of air bubbles. If such bubbles still remain in some places, they should be pierced with a needle, carefully releasing the air from under the self-adhesive film.

If the self-adhesive film is not glued correctly, then the new, adjustable self-adhesive film will only adhere completely after a few hours, so that the self-adhesive film can be removed from the solid base and pasted again.

Pasting large surfaces. They can be pasted over only if they absorb moisture well. It is necessary to cover such a surface with wallpaper glue and, while the glue is wet, stick the film, adjusting it to the desired position. Then you need to press it with a rag or sponge and smooth it out.

If the self-adhesive film sticks too quickly, you should sprinkle the surface with powder or talcum powder. In this case, the self-adhesive film will not stick so quickly, which will allow it to be moved to the desired position. If bubbles appear, pierce the self-adhesive film with a needle or pin and release the air.

Sticking to glass, synthetic materials and metal. The surface is slightly moistened with an aqueous solution with the addition of detergent. Then you should completely remove the back paper side from the self-adhesive film and place the self-adhesive film on a moistened base. This will make it easier to adjust the self-adhesive film to the desired position. When the desired position has been achieved, lightly press the self-adhesive film and, using a rag or sponge, smooth the surface towards the edges and downwards, removing water.

Caring for self-adhesive films

Warm water and detergent is usually sufficient for cleaning. If the dirt cannot be washed off, you can remove it with ethyl alcohol. It is prohibited to use products with scratching components, nitro thinners, acetone or cleaning benzine. If glue appears along the edges of the self-adhesive film, you should moisten a rag in alcohol and wipe it off. For velor films it is recommended to use warm water.

MDF panels Soyuz Who among us is not ready to spit in our hearts on a wall that stubbornly refuses to be leveled during any repair? Who among us isn’t tired of endlessly whitewashing ceilings because the neighbors won’t, no, they’ll flood it? Admit to yourself that the endless rush of repairs is already making you and your relatives’ heads spin. I want to stop at least once and be satisfied. So how can we hide the shortcomings of our home quickly and reliably? MDF Soyuz panels will help us with this. Do you want to know what this thing is? Read on and delve deeper into the essence of the phenomenon.

MDF Soyuz panels are a unique material that will make it easier for you to change the interior of a city apartment, office or even a country house. These panels are most often used to decorate walls, although the material is also perfect for decorating ceilings. Interior redevelopment using Soyuz MDF panels can be carried out through the creation of additional partitions, arches and columns. Of course, these will not be real Greek columns from the Parthenon Temple, but, on the other hand, they will not be so heavy. The panels are easy to install and remove, as they do not require special fasteners. This feature is important when it is necessary to replace pipes or wiring. If you handle the material carefully, it can be used repeatedly.

MDF Soyuz panels are also beneficial in that they provide excellent sound absorption in rooms, as well as good thermal insulation. Another positive quality of this finishing material is that caring for it will not cause difficulties. It is advisable to wipe the panels every month with a damp cloth or sponge with any detergent, except those that contain abrasive elements. The most important thing is not to go into battle with dust with a wet rag and a full bucket of water.

MDF panels are characterized by high density and homogeneous composition. This makes it possible to produce a variety of product profiles using mechanical processing of the starting material. Union panels are distinguished by practical sizes. Size of one panel: 2600x168x7 mm. Its area is 0.4368 m2.

Today, customers are offered a collection consisting of more than 50 types of decorative finishes. Panels from the Classic series are available in both white and marble, ash, cherry, and light oak. Economy panels are represented by varieties of marble (pink and green), marianna, gray, old, pacific, oak (knotty, light, dark), maple, silver ash, green, Alaska, pear, birch, malta, mahogany. Already from this list one can judge what various modifications the Soyuz panels have. Such an abundance of colors makes it possible to select panels for any interior. To create a decorative coating, paper-based films are used. In addition, the surfaces of this finishing material are made both traditional (glossy or matte) and the now fashionable structural ones. In any case, the choice of purely external characteristics is always yours.

You may ask how much this amazing finishing material costs. Wholesale prices for various MDF Soyuz panels on average are as follows: Classic, Economy - 3 USD; Medium – 3.5; Modern – 4.5; Fantasy – 6.5.

It should be noted that photocopies of fire and hygiene certificates for this product can already be found on the Internet. This way, at least most of us will be able to verify the quality of these products in advance. In addition, the developers claim that all materials used for production are approved by the Ministry of Health of the Russian Federation.

Base material

Thanks for the answer. I would also like to know if there are any special features in using MDF? For example, what is the best glue and tape to use, whether MDF is glued and if so, then with what, relation to acrylic (varnish, primer), etc.

From experience working with MDF: (I’ll tell you right away to use this surrogate only if absolutely necessary) pavolok is not needed, gesso is used only as a light primer, there is no need to scratch it with anything - a flat surface is ideal for work. Ready-made artistic primer with pre-impregnation is better suited acrylic (if the primer is acrylic).

MDF can loosen over time, it is afraid of moisture, its density is greater than that of a natural board, so it is heavier.

Moreover: you can use ready-made Greek gesso on canvas as a primer - this is just suitable for perfectly flat surfaces.

Guest I'm very interested, could you please clarify some details, namely:

This means that this is obviously a bad thing, but what qualities make it so?

What is acrylic in its pure form, suitable for impregnation? Is it possible to quote some label, otherwise I don’t know what to look for?

Do you mean rolled primed canvas that is glued to MDF? What kind of glue? Does this make MDF more suitable for work?

Again, can you provide the label?

MDF is a good idea, but it was implemented without taking into account open use, i.e. MDF is subsequently covered with various laminates for furniture use. I will not describe how MDF is produced - detailed technical descriptions can be found on the Internet. https://shkafy-kupe.ru/articles/materials/mdf.htm, etc. The main disadvantage of MDF is the weak connection between small wood fibers. Destruction usually begins at the corners of the MDF board. If the process has begun, then everything will crumble into fine dust. You can seal it with varnish, preferably acrylic - it’s more reliable. MDF is best suited for small jobs. I will answer in more detail: MDF board is mainly obtained by pressing under high pressure. If we make a large board more than 2 meters high and place it, then at the very bottom there will be excess stress on the internal structure of the material. Small MDF particles under constant pressure begin a gradual reverse movement obtained during production under pressure - the lower edges are gradually loosened and destroyed. That’s why small parts for furniture are made from MDF, and always for laminate, which keeps the pressed mass within the framework that was originally given to it.

An ordinary construction acrylic primer - a milky white liquid - is quite suitable for impregnation.

No, MDF does not become better with any processing option. Its disadvantages are inherent in the production.

Last edited by: Victor Demidov (30 Dec 2006 01:57), edited 1 time in total

Victor Demidov Thank you for your detailed answer.

In this case, can double-sided burlap covering play the role of a laminate? (With primer, of course, on the front side)

I heard somewhere that PVA and acrylic cannot be used together, is that true?

Are there any analogues to MDF in this price category - for example, chipboard or fiberboard? What are their weaknesses and strengths compared to MDF?

Victor, it seems to me that you are exaggerating a little about the fragility of MDF. Its closest relative is the well-known hardboard, fiberboard. Its operational properties have been well known to all of us for decades. MDF differs in manufacturing technology in that higher pressures are used when pressing it, which gives greater strength and resistance to changes in humidity compared to fiberboard. Ruthenium I said about fiberboard above, but particle boards (chipboards) are a thing of the past; they are inferior to MDF in many respects, of which strength and durability are the main ones.

Victor, what can you say about gypsum board as a basis for painting?

Burlap - ? – why make it so complicated? In this case, it is better to paint with oil paint.

I drew a diagram of the action of destructive pressure in a slab when installed vertically. As you can see from the picture, the bottom corners and the bottom end itself are very critical here; this place (more precisely, the bottom end) can and should be covered with burlap.

I heard somewhere that PVA and acrylic cannot be used together, is that true?

Read more carefully, I talked about acrylic impregnation for acrylic art primer and about PVA glue for gluing ready-made gesso. Of course, there is no need to mix these things; they have different film formation. If you glue on PVA, then make the preliminary impregnation from PVA

50% pva + 50% water. PVA is better than American, the color of baked milk. But PVA has a limited service life in the product.

We didn’t work with chipboard and fibreboard, so I can’t say anything about these materials.

mdf2.jpg 5.28 KB • 171

Pressure in the MDF board during vertical installation.

Installation

There are several options for mounting MDF panels:

on a specially installed frame;

On the frame

on glue.

On glue

It is the second method that is more popular; it is less time consuming. The only important nuance is landing on a perfectly flat wall, so you will have to prepare everything in advance.

The entire process of gluing panels is divided into several steps:

- exact knowledge of the meters in the room where the panels are planned to be glued. This will help minimize waste;

- preliminary adjustment of all parts of the decor. This will make it easier for you to decide and place all the pieces in the right places for later gluing;

- the next step is to attach the starting molding in the right places;

- Now you can glue the panels according to the order. Here's how to glue MDF to a wall. The glue layer must be thin and uniform to avoid defects. It is applied in thin strips evenly spaced from each other;

- All joints and junctions of MDF for the ceiling must be hidden behind pre-prepared panels.

Another option is to use lathing, thereby leveling the walls for subsequent fastening of the panels using self-tapping screws.

For more information about installing MDF panels, watch the video:

MDF furniture: pros, cons, is it worth buying

The appearance of furniture made from MDF facades is becoming increasingly popular compared to products made from chipboard. The material is highly environmentally friendly , as it is made from a wood fiber component using the methods of drying, grinding, steam pressing with further finishing and bonding. As a result of processing, the appearance of the furniture acquires an attractive and expensive texture. The competitiveness of the product in relation to metal and wooden furniture structures increases.

Idea of a façade slab

MDF construction consists of a board made from medium-density wood fiber. It is considered an environmentally friendly material due to the fact that the manufacturing process does not contain the addition of chemical binders to the product. The role of a binding impurity is played by the natural component lignin, which is a component of wood.

The material is pressed from dry fine particle fiber under the influence of high temperatures and pressure. As a result of this, the wood releases a lignin substance that binds all components. The production process involves imparting special properties to the product: water resistance, biostability and low flammability.

Initially, MDF began to be manufactured in 1966 in the United States. China is currently the leading country in the production of material on the world market.

Taking into account operational criteria, facades are divided into certain types of slabs, which consist of:

- From slabs intended for storage in dry rooms.

- Made from wood materials that are resistant to moisture.

- From slabs used for the manufacture of furniture with a high load of structural elements used in a normal room.

- Made from heavy slabs used in damp conditions.

Use of material

Products made from MDF have high performance indicators. For furniture production, slab widths from 18 mm . Material used for manufacturing:

- Facades for the kitchen.

- Designs for sliding wardrobes.

- Countertops for kitchen furniture.

- Table tops for bar counters.

Furniture elements are formed from slabs according to measurements. After which they are treated with paint and varnish coatings in 3 layers . This increases the product’s resistance to mechanical damage and temperature changes. To increase the strength and moisture resistance of the product, varnish or polyurethane enamel is applied to it.

MDF facades for sliding wardrobes are covered with polyvinyl chloride film. It is applied to the base of the slab using special equipment under pressure and high temperatures.

The panels are used in the manufacture of kitchen countertops. For them, a slab with a thickness of 25-40 mm . The design is applied using a special film that has its own finish. Tabletop slabs made to look like natural stone or wood texture are popular. They repel moisture well and are durable.

Advantages of MDF panels

Wall panels made from MDF have a number of undeniable advantages:

- Versatility. The material is suitable for finishing not only walls, but also ceilings. The panels can be used in almost any room.

- Attractive appearance. The variety of panel designs allows you to choose the material for interior design in any style.

- Simplest care. The walls on which the panels are installed do not require special care. To remove dust, it is enough to occasionally wipe the walls with a damp sponge, and to remove stains, you can use detergents.

Advice! It is necessary to take into account that the panels are moisture-resistant, but not waterproof, that is, they tolerate the action of humid air well, but do not tolerate direct contact with water, so you should not install them near the bathtub and sink.

- Simplest installation. To install the panels, you will not need to level the walls; even the old finish, provided that it holds tightly, does not need to be removed.

- Economical. The low cost of panels and components, as well as the ability to carry out repairs yourself, provides significant cost savings.

Availability of advantages

Before buying furniture products made from MDF, you need to study all the advantages of the material. The designs have the following advantages:

- The furniture is environmentally , as it is made from natural wood fibers using modern technologies. The binders in the composition range from 8 to 10 mg .

- Wood fiber material is highly hydrophobic . Constant moisture on the surface of the slab allows the liquid to remain on the surface rather than being absorbed. This protects furniture from premature wear and extends the life of the product. Both thick and thin slabs have these properties.

- The ability to choose colors and patterns on panel surfaces attracts more customers when choosing furniture. MDF structures are treated with wood veneer on the outside and then varnished. The top can also be covered with colored melamine. This approach ensures the choice of a suitable slab design, taking into account the interior style of the room.

- Applying a melamine coating and durable varnish to the base of the slab provides the product with a long service life and makes it resistant to external irritants.

- Furniture structures made from MDF are easy to care . They are simply wiped with products intended for furniture care. In case of damaged parts, they can be easily replaced with new ones.

- The finished product does not contain any unpleasant odors , minor impurities quickly evaporate.

- The service life of structures ranges from 10 to 30 years .

- The resistance of the material to damage is obtained due to the strength of the wood fibers from which the furniture is made.

What types of moisture-resistant wall panels for bathrooms are available?

There are quite a few options for finishing a bathroom; to determine the best material, it is important to analyze all the advantages and disadvantages of each of them. Finishing options can be divided into:

- rack typesetting;

- tile materials;

- sheet fabrics - it is advisable to choose them for large rooms.

Characteristics of PVC wall panels for the bathroom

PVC is the most inexpensive material for finishing a bathroom. The production technology of polyvinyl chloride makes it possible to produce panels with imitation wood, natural stone or ceramic tiles in different colors. The main advantage of the material, in addition to moisture resistance, is that it is non-toxic even at high humidity. Interesting interior solutions using PVC panels for the bathroom are presented in the photo gallery.

PVC in the interior is not inferior to tiles

Related article:

Characteristics of MDF panels for the bathroom

MDF panels for the bathroom are suitable only with a laminated coating, it prevents moisture from getting on the chipboard. If we compare the characteristics with PVC, MDF has undoubted advantages:

- high strength;

- does not require a large number of supports, and therefore the structure is more durable;

- the finished product is painted;

- has heat and sound insulation.

The only drawback can completely negate all the advantages: hydrophilicity. Unfortunately, chipboard absorbs moisture; it will take a little time for the board to become unusable. To prevent this effect, it is necessary to apply additional coating and completely isolate unprotected areas.

The finished MDF sheet does not require additional decoration

Characteristics of fiberboard bathroom panels

Fibreboard fibers have a low density, and therefore are susceptible to moisture and can swell. To use fiberboard in conditions of high humidity, they must be treated with a composition with a moisture-resistant effect. For use in the bathroom, it is recommended to choose laminated hardboard - fiberboard sheets that are treated with bitumen impregnation, then covered with a film and a special composition with protective properties. Like MDF boards, it is necessary to control the integrity of the film coating; this is additional protection against high humidity; it must be without damage. During installation, all butt joints are treated with sealant.

It is not advisable to use laminated fiberboard in the bathroom

Related article:

Characteristics of moisture-resistant panels based on chipboard

Chipboards are made from shavings and small chips. Conventional slabs, like fiberboard, are afraid of moisture; they swell and lose their shape, which is not restored even after drying. Manufacturers produce moisture-resistant boards that contain binding components, and the surfaces are additionally laminated. For bathrooms, you should choose a material with a waterproof effect. In terms of cost, it is equivalent to moisture-resistant MDF for the bathroom, however, MDF has much better characteristics.

Laminated chipboard is also not entirely suitable for the bathroom

Related article:

Characteristics of acrylic panels for the bathroom

Acrylic lamellas are innovative developments of manufacturers. The color and structure of the material is affected by the concentration of additives. The surface gloss is much higher than that of PVC and MDF. The main advantages of acrylic can be highlighted:

- high strength;

- resistance to mechanical damage;

- resistance to abrasion and light reflection;

- environmentally friendly product;

- absolutely waterproof.

The only drawback of acrylic does not overshadow the entire list of advantages - it is a high price. Only aquapanels can be considered as its competitor.

Assortment of acrylic slats for the bathroom

Glass wall panels

Tempered glass slats are quite popular for finishing bathroom walls. A smooth and shiny surface beautifully reflects glare from lighting, this effect will visually expand the space and the room will look radiant. The advantages of finishing include:

- not afraid of temperature changes;

- resistant to high humidity;

- easy care;

- durability.

Bathroom interior with glass panels

Other types of wall panels

When choosing a material for finishing a bathroom, one cannot help but highlight aqua panels; today this is the most ideal solution. They are a fiberglass mesh filled with weightless expanded clay. Among the positive qualities it should be noted:

- resistance to high humidity and temperature changes;

- easy care;

- beautiful appearance;

- the material can be bent.

During installation, the aqua panels are attached to the wall surface using special glue on a pre-assembled frame.

Aquapanel is the best solution for the bathroom

List of disadvantages

Considering the number of advantages of furniture products made from MDF, it is worth familiarizing yourself with the minor disadvantages. The significant disadvantages of the designs are:

- High price indicators.

- Instability to ignition and thermal contact of the material, which leads to defects in surfaces located near heating devices.

- Swelling of a material under the influence of moisture . When condensation forms on furniture under the influence of hot steam, it deforms with peeling of the film in the area of the joints.

- Susceptibility to damage due to mechanical stress. The material has a medium density, which makes it impossible to reinstall the fittings.

- Exposure of the product to sunlight , which results in fading of the finish.

- The duration of production of structures is at least 3 weeks .

It is worth noting that MDF facades for the manufacture of furniture products are a modern material and have many advantages and a minimum of disadvantages. The material is not only highly environmentally friendly, but also affordable and multifunctional. Compared to chipboard, MDF structures do not wear out as quickly and look more respectable, which allows facade products to be in demand in the furniture market.

Source: plusiminusi.ru