Advantages and disadvantages of a bed with a lifting mechanism

The main advantage of such beds is space saving. The sections under the bed have enough space to store bulky items. Partially, such a bed can replace a wardrobe. Due to the fact that access to the internal filling is carried out by lifting the top bar, there is no need to free up space next to the bed in order to freely pull out the drawers.

In addition, the flooring or carpet will not suffer from the wheels. Even if you do not use the bed as a storage place, the lifting mechanism will be convenient. Thanks to it, it is much more convenient to clean under furniture.

A bed with a lifting mechanism will be a good solution for a small bedroom.

Do such beds have any disadvantages? Alas, the cost of the structures is an order of magnitude higher than the price of conventional models without a lifting mechanism. The second nuance is less significant. Dust will regularly accumulate under the bed, so things will have to be stored in boxes or containers.

Advantages of lifting beds

Compared to standard beds, lift-up models are practical, multi-functional and ergonomic. Such designs are convenient to use in limited areas. They have a spacious interior space where you can store bed linen, home clothes, bedspreads, pillows and blankets.

Other advantages include:

- high reliability and durability;

- easy to use;

- dust and dirt do not collect under the bed;

- saving money when purchasing;

- different configurations.

When choosing a bed, it is important to consider not only the quality of the product itself, but also the lifting mechanisms. If the installed elements are not the best, you can replace them with gas ones. They are more durable and provide long-term and comfortable use of the bed.

Characteristics of a bed with a lifting mechanism

Typically, such beds are equipped with the most reliable components and durable slats. That is, the design is created taking into account all mechanical loads. The furniture consists of a flat base, a niche and a built-in mechanism, due to which the upper part rises up or to the side.

There are several types of bed lifts.

Most modern models have a gas lift, but there are also beds with spring and manual mechanisms. You can assemble such furniture with your own hands: it is not as difficult as it might seem at first glance.

Types of lifting mechanisms

In modern models, a gas lift or spring mechanism is more common. The manual hinge system was popular several decades ago; now such furniture is rare.

The mechanism can be made of different materials.

Manual

The simplest mechanism without auxiliary devices that simplify lifting the base. But at the same time, it is the most durable. It works due to the movement of furniture hinges. During lifting, all the weight rests on the hands, so not everyone can access the internal contents.

The French folding bed transformation mechanism has become widespread.

For a child, this task will be difficult to accomplish. If handled carelessly, the housing may become deformed. Especially if the bed is made of inexpensive chipboard that does not withstand frequent use.

Spring

This is a budget option that is installed in economy class beds, as well as in some mid-price models. When lifting, the weight of the body partially falls on the springs, thanks to which even a person who does not have developed physical strength can cope with it.

A double bed with a lifting mechanism on springs costs significantly less than its counterpart on gas shock absorbers.

However, it will be difficult for the child to lift the base. A serious drawback of the mechanism is its short service life. Typically, manufacturers claim 5 years during which the device remains usable. The springs are then stretched.

On gas shock absorbers

Gas lift is the most advanced mechanism. Lifting the bed requires virtually no physical effort: the bulk of the weight falls on the device. It works silently, the base lowers and rises smoothly, and is securely fixed in a vertical position.

Lifting mechanisms can be manual, with springs or with gas shock absorbers.

The mechanism can be installed in any bed. Manufacturers claim a 10-year service life for the device. The only drawback is the high cost compared to other models. But in the long term, the purchase will be profitable.

Everyone chooses their own bed transformation mechanism.

Possible difficulties

Of course, professionals with extensive experience in assembling various types of furniture can easily handle assembling beds with a lifting mechanism. But beginners in this matter may encounter some difficulties, which can be found in the table.

| Possible difficulties | Solution |

| Need for drilling holes | Holes for fasteners will need to be made in different parts of the structure. It is especially important to properly organize them in the headboard for its secure fixation on the frame. A screwdriver is required to create the holes, and the headboard is secured with screws. |

| Assembly and installation of gas lift | The installation process itself is quite complex, so the work must be done without haste, carefully, and consistently. It is important to maintain symmetry in work and adhere to safety measures. |

| Mistakes in marking the bed frame | An error at this stage will negate all efforts, so it is worth reading the assembly instructions from the manufacturer of this model in advance. You can also ask the opinion of experienced furniture makers. |

Remember a few more important points.

I've always liked convertible bedroom furniture. The available space under the mattress allows you to put a lot of things into the bed frame; this replaces a closet or chest of drawers, which is important for a small bedroom. I decided to make a double bed with a lifting mechanism myself.

I have been making furniture in my small workshop for a long time. Having the appropriate equipment and a large set of tools made solving my problem much easier. After a short search in the media, I decided on a bed design with a lifting mechanism and gas shock absorbers.

How to choose a bed with a lifting mechanism

To choose suitable furniture, you should focus on the operating conditions:

- if you do not need to regularly raise the base (for example, things that are rarely used are stored in the bed), you can purchase a model with a manual mechanism;

- For regular use, spring installations or a model with gas shock absorbers are suitable;

- For a children's room, it is better to choose a bed with a gas lift, but one with a spring mechanism is also suitable if you plan to change the furniture within a few years.

You can always get great pleasure from creating a bed with your own hands.

It is important to pay attention to the materials of manufacture, namely the strength of the lamellas. Budget models usually use inexpensive chipboard, which can quickly become unusable. The best in comparison with them will be beds made of MDF. This material is durable and safe.

Once the base is raised, you will have access to a lot of space.

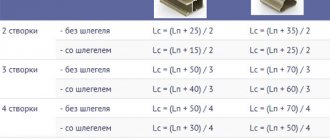

The larger the furniture, the more weight will be placed on the mechanism. According to the standard, such beds are 2 m long and 90 cm wide (single) and 2 m (double). The dimensions of the product must be taken into account when choosing a mechanism. It is worth checking with the manufacturer what loads it is designed for.

How to assemble a bed with a lifting mechanism with your own hands

If you select high-quality materials and accurately calculate the drawings, you will be able to assemble a bed with a lifting mechanism with your own hands. For production, chipboard, OSB, MDF or plywood are used. The body can be made from solid wood, if possibilities permit.

But the lifting bar should be made of lighter materials so as not to put a high load on the mechanism. It is better to opt for MDF: these are safe boards made from chips and resin, they are durable and easy to use. It is also important to choose upholstery fabric and filling.

Required tools and fasteners

Before you begin assembly, you need to prepare the manufacturing materials and the necessary set of tools:

- screwdriver;

- grinder with a disc for metal;

- welding machine;

- jigsaw;

- construction hair dryer;

- furniture stapler;

- roulette;

- level;

- pencil;

- steel strips;

- ties, corners, brackets.

Before work you need to prepare all the necessary tools.

Stages of work

The first step is to cut out the parts according to the drawings.

Further instructions for assembling a bed with a lifting mechanism are as follows:

- body assembly;

- installation of legs, corner ties;

- installation of a lifting mechanism;

- frame fastening.

At the first stages, the work is carried out in the same way as assembling a regular bed. The only difference is the installation of the lifting mechanism.

Assembling the base and box

The perimeter of the body consists of a headboard and 3 drawers, which must be connected to each other with furniture ties or corners and brackets that are fastened with screws. It is better to do the work with a partner who will hold the parts being connected.

Every part of the bed must be thought out.

It is important to check the evenness of the floor: if the bed is installed skewed, the mechanism will not be able to function normally. How to assemble the base and body:

- parts are connected on the floor to avoid distortions;

- to level the corners, use a construction square;

- the screed is carried out using construction corners, the heads of the screws should be slightly buried in the thickness of the slab;

- the joints are additionally glued;

- cuts are processed to remove burrs;

- For double beds, it is recommended to make an additional longitudinal post in the middle.

Different models can use a variety of longitudinal force elements.

After assembling the box, you do not need to immediately tighten the bolts. This is done only after the structure is level. And checking the accuracy of the angles. Transverse partitions are installed in the finished box, which will create sections for storing things.

Serial furniture is usually equipped with an assembled mechanism.

This stage can be skipped if there is no need to create separate “boxes”.

Important! Wooden materials must be pre-treated with stain, sanded and varnished after assembly.

The lifting box is assembled according to the same principle as the base. For production, 3 drawers are used. The base of the bed frame and slats are attached to them.

Installation of legs and installation of corner ties

The legs are attached either to special platforms that are located on the frame elements, or bars (40x50) are screwed into the structure with screws.

Important! Using a level, you need to determine the height of different sections in order to align the legs in height.

The base on which the mattress will subsequently be placed is usually equipped with slats.

The most important stage in assembling the body is connecting the parts with corners. Before fastening, you must check that all angles are exactly 90 degrees. After joining, it is better to treat the joints with glue and remove any excess immediately. Installation of the lifting mechanism

Important! The weight of the lift bar falls not only on the arms and shock absorbers, but also on the fittings. Therefore, it is necessary to choose the most reliable fastenings.

The berth with built-in lifting mechanisms ensures ergonomic space.

You can make the lifting mechanism yourself, but it is better to order a ready-made one from a furniture manufacturer or in specialized stores.

How to install the mechanism:

- the upper bar of the mechanism is mounted to the base of the box and the sheathing of the berth; this will require a metal stiffener bar made from rolled angle steel;

- To facilitate the sliding of the hinges, a lower support bar is attached to the box.

After installation, you need to check the strength of the fasteners and tighten (but do not overtighten) the bolts.

Attaching the frame and mattress supports

Using self-tapping screws, slats (approximately 20x80 mm) are attached to the inside of the lifting bar. They are aligned along the lower edge of the perimeter.

Long-term and uninterrupted operation is only possible with proper assembly of the furniture.

Slats are placed on the slats, the length of which corresponds to the length of the furniture. They are mounted on support rails in 15 cm increments. You can use plywood if an additional central post is installed.

What you will need

Before you begin installation work, you should prepare the necessary equipment. To assemble the bed you will need a set of tools and additional materials.

Tools

The standard configuration of the bed includes various fasteners, to work with which you will need screwdrivers, ring wrenches and a screwdriver with a set of attachments. Since modern types of bedroom furniture often use Euroscrews with a hidden head and internal hexagon, it is also worth preparing keys for confirmation.

In addition to the basic tools, during installation work you may need a tape measure and a building level.

Materials

The assembly kit consists of fixing elements, body parts, lifting mechanism, mattress and decorative components. Before starting installation, it is worth checking the availability of all materials and laying them out at the work site.

Instructions

To properly assemble a bed with a lifting mechanism, you must read the instructions. As a rule, installation instructions are included with the bed. Having previously studied the manual, you will be able to get a general idea of the work ahead and calculate your capabilities. If necessary, assistants can be hired for further assembly.

Common problems and errors

The main problem when assembling a bed with a lifting mechanism is non-compliance with calculations and inaccurate connection of corners. It is very important to respect the dimensions of the slats. If it is not possible to cut sheet material at home, it is better to order a cut.

Classic double bed sizes with an additional lifting mechanism.

Precise joining of the corners will ensure the reliability of the structure and the precise fit of the lifting bar to the base. If a lifting mechanism with gas lift is selected, it is necessary to clarify its reinforcement: for which bed models it is suitable. It is mounted using nuts with a locking ring and fluoroplastic washers. The fastening cylinder should be facing up.

Bed with wide sides, made of wood.

It happens that the lifting bar is quite difficult to lift. It could be the fasteners that are screwed on too tightly. When installing, they must be tightened all the way and then loosened slightly to obtain minimal play. Then make sure that the mechanism works correctly.

The entire assembly process must be carried out strictly according to the instructions.

To make it easier to lift the slats, you should install handles on the frame, as well as a mattress stopper. This simple method will make using the bed even more convenient. A bed with a lifting mechanism, assembled by hand, is much more reliable than factory models.

To complete the assembly, all that remains is to lay the bottom of the bed and put the cover on its perimeter.

It's all about being able to choose the materials yourself. Such furniture will cost less. Considering that the assembly process is not that complicated, this can be a serious budget saver.

Detailed bed assembly diagram

Like any cabinet furniture, a bed with a lifting mechanism is delivered disassembled; its assembly is paid separately. But if you wish, you can save money and assemble the bed yourself. Instructions with step-by-step actions are below.

- Forming a bed frame. First of all, the front and two side panels are fastened together. A central crossbar is attached to the resulting U-shaped structure (it acts as a support for the future bottom of the box). Then the headboard is attached and the bottom is laid. The lower body is ready.

- Installation of the lifting mechanism on the assembled box. Serial furniture is usually equipped with an assembled mechanism, which must be secured to the lower body. The process is simple, but requires attention and accuracy. It is important to place the parts symmetrically, without errors, on the intended side for each side.

- Assembling the top of the bed. The base on which the mattress will subsequently be placed is usually equipped with slats. Each plank is secured on both sides in special holders. For double models, at least 30 slats are calculated, so assembling the base may take some time. But such an orthopedic surface is worth the resources spent, because it ensures correct and comfortable sleeping position.

- Attaching the base to the lifting mechanism. This step is difficult to complete on your own, so make sure you have an assistant in advance who can hold the top of the bed and secure it evenly to the folded mechanism.

The assembly of the functional bed is complete. Now you need to check the operation of the lifting mechanism and the strength of the fastenings. If necessary, lubricate the rubbing parts to prevent squeaks during operation.