Recently, many have been trying to do the installation without using laminate flooring thresholds. The only advantage is the absence of thresholds, but there are so many disadvantages.

- Introduction

- § 1. Disadvantages of laying without seams

- § 2. Laying laminate flooring without thresholds

- § 3. Thresholds for laminate

- § 4. Application of thresholds

- § 5. Methods of fastening thresholds

- Conclusion

INTRODUCTION

For laying flooring in a residential area, it is recommended to use class 31 laminate. It is worth paying due attention to the quality of the locks, geometry and density of the panels. If one of these parameters fails, then, in the end, it will lead to big troubles.

Threshold for laminate

Weak laminate joints will make themselves felt by the appearance of cracks, and this will happen much earlier if laid on an uneven floor. The density of the panel affects how your laminate floor will react to changes in temperature and humidity. The harder the panel, the more reliable the assembly will be, the fewer gaps there will be.

Laying laminate flooring near doors. Detailed instructions

Here is our laminate with an oak texture, imitation of an oak board:

The laminate package contains detailed installation instructions. Laminate is cheap, there are no barcodes or inscriptions on it. Perhaps he is from China.

We also bought a roll of lining:

Let's make some minor comments. The installation process is described on the insert in each package of laminate flooring. We have two rooms, we will do them separately, because the floor in them is floating, and it will “float” in each room in its own way. If you make a rigid connection between the floors, the seams at the thresholds may come apart. Let's make the rooms separate and put an aluminum threshold between them. Another point: when we counted the number of stripes in the room, it turned out that if we start with the whole first strip, a two-centimeter strip will remain at the end. Therefore, we will cut the first starting strip almost in half, so that at the end it will also be a little more than half the width of the strip. We will start from the door side. This method is incorrect, but it allows you to conveniently design the threshold and push the laminate under the door frame, since the doors are already installed.

We rolled out our backing. At the doors we will insert the backing in a piece in order to save money, so as not to cut the whole one. We tape it down so it doesn't move. Then we cut the laminate into two strips.

We will install the laminate under the door frame. If we start laying from the doors, the pieces of laminate can be freely moved and driven under the frame without any effort. If you start from the other side of the room, then the entire plane will be folded, and this plane will no longer be able to be moved normally. You will have to put some pieces into the doorway. And in our case, a solid piece of laminate will go to the threshold.

We prefer to cut laminate with a circular saw. Of course, we also have a jigsaw, but with a saw the cut is much faster and smoother.

The circular saw is secured with special clamps. In this case, we don’t have them; we just screwed the saw to the bench. Of course, you can’t do this, because it’s all very unsafe, you need to be extremely careful and attentive when working.

We can freely move the cut strip, fold it, and drive it under the frame.

The plank fits neatly under the frame. Next will be the second row of laminate, and we will put a threshold under the doors. If the doors are installed correctly, with a normal gap, then driving the laminate under them will not be a problem. The doors will look as if they were originally placed on laminate.

In the end, we laid the two initial strips and adjusted the laminate to the frame. The rest of the installation is already done in the same way - cutting and laying strips. There is nothing complicated here.

The laminate needs to be customized in color - it should be monochromatic. We had to sort the light strips that were very different from the rest. We'll put them in another room.

Here's what we ended up with:

Laying the last plank:

All the laminate has been laid, all that remains is to screw in the baseboards. Skirting boards are attached only to the surface of the wall; under no circumstances should they be attached to laminate flooring.

All rights to the video belong to: Zhelezjaka

§ 1. DISADVANTAGES OF LAYING WITHOUT SEAMS

Recently, many have been trying to do the installation without using laminate flooring thresholds. The only advantage is the absence of thresholds, but there are so many disadvantages.

Missing thresholds between laminate

Firstly, it is much more difficult to do the styling; it will require certain professional skills. Secondly, in order to lay such a floor without seams, you need to carefully study the geometry of the room. Without seams, you can lay laminate flooring over an area of up to 50 m2 or in a sheet of no more than 10 meters.

Any specialist will confirm to you that there must be a gap between the rooms, as there is a danger that a bulge will appear near the door. To prevent this problem, use a laminate floor release strip.

The situation will be even more dangerous if laminate flooring without thresholds is installed on an area of more than 150 m2. The need for gaps is supported by the fact that it is very difficult to achieve a level base over a large area, which is a mandatory requirement for seamless installation. In this case, it is better to buy thresholds for laminate flooring so as not to have problems with the flooring in the future.

In addition to all this, if just one panel is damaged, you will have to dismantle almost the entire floor to get to the board that has become unusable.

We make a threshold for the balcony from laminate or install a plastic one

Nowadays, the balcony is no longer exclusively an auxiliary room in the house. It can serve as a bedroom, guest room or kitchen. Therefore, renovations in this part of the apartment should be carried out conscientiously, using modern technologies and materials. When you are arranging a loggia, an important stage of work is laying the floor and decorating the threshold.

Some owners of apartments with balconies even dismantle this step between the room and the auxiliary space, mistakenly believing that it is not needed. However, the balcony threshold performs several useful functions. Firstly, it makes the balcony structure more durable. Secondly, it keeps the room warm. When the door to the loggia is located in line with the floor, cold air easily penetrates into the room. Protecting this area from freezing temperatures will not be easy. Therefore, the best option is to raise the door a little. Thus, the threshold acts as a heat-insulating element.

§ 2. LAYING LAMINATE WITHOUT THRESHOLDS

If all of the above doesn’t scare you, you can safely do the styling without seams. The technology for assembling a single structure is not complicated and is almost no different from the usual one. All installation technology can be found on our website, or in the instructions for any laminate. Just before you start installing it yourself, consult with a specialist to see if this can be done in your apartment. He will be able to give you a lot of practical advice on how best to lay laminate flooring.

If you decide to lay laminate flooring without thresholds, do not forget about expansion joints. At the walls you need to leave up to 10 mm. Without this, your floor will quickly become unusable. This is written in more detail in the article about baseboards.

The laminate sheet can change its geometry in width and length; unfortunately, it is not possible to guess this. To prepare the flooring for such surprises, you can groove the wall a little. In this case, the floor will never hit the wall and will not swell.

If the combination concerns only two adjacent rooms, for example, two adjacent rooms, then laying a single integral structure, done according to all the rules, should not cause problems.

Laminate threshold

How to make a threshold for a balcony from laminate with your own hands - instructions:

- The first step is to putty the threshold.

- Measurements are taken and the necessary laminate elements are cut out. In most cases, one strip may be enough, since laminate comes in different widths and it is possible to choose the optimal solution. When cutting the material, use a wood saw with fine teeth, a hacksaw for metal or a jigsaw.

- To beautifully design the joints between the wall and the laminate, starting guides are used. We cut them to size and fix them around the perimeter.

- Apply silicone sealant or liquid nails to the base of the threshold and glue the laminate.

- The final stage is cutting to size and installing a decorative corner.

§ 3. THRESHOLDS FOR LAMINATE

In some cases, when laying laminate flooring, it is almost impossible to do without thresholds. So, for example, if you are installing laminate flooring in the hallway, and there are tiles in the kitchen, then multi-level thresholds for the laminate will help hide the unaesthetic joint.

Thresholds for laminate

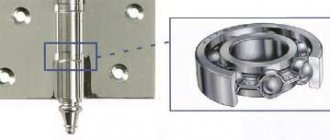

Thresholds are a kind of decorative strip. There are several types of metal trim:

- edging - used for pressing different types of coverings with different heights;

- joint - used for pressing coatings having one level;

- corner with rubber insert - it is used for flights of stairs and steps.

Thresholds for laminate flooring can be made from a variety of materials, but the most popular and in demand are thresholds made of steel, brass and aluminum. Metal thresholds, as a rule, are covered with a special film that imitates gold, silver, wood, and so on. Wooden, plastic and flexible laminate thresholds are also widely used, but are less popular due to low efficiency and wear resistance.

Purpose

The product performs two important functions:

- decorates the joint between materials and hides installation flaws;

- protects the passage from debris and dust;

- prevents the edges of materials from collapsing.

Its types

Transitional

In this case, a Quick Step laminate threshold is used, which makes it possible to connect coatings located in different horizontal planes. The difference can be 3-20 mm.

Thresholds for laminate Ceramic floor tiles - features of selection and installation” href=”https://shkolapola.club/drugie/plitochnye/1286-keramicheskaya-plitka-na-pol”>ceramic floor tiles;

- linoleum;

- carpet

- ceramic floor tiles;

Straight

It is usually installed at the border of rooms. It is used to create joints between floor coverings located on the same horizon. This is very important since its design is flat.

Angular

Very often it is called staircase. Used to secure the edge of the flooring near steps. Very often they are rubber, preventing the sole from slipping. If you install laminate on the threshold, for example, when going out to the balcony, you will also need it.

With rubber pad

Final

Their purpose is to cover the edge of only one of two floor coverings located at different heights. Also, such a threshold for laminate flooring is suitable for decorating the edge of raised floors as they approach a balcony, staircase or hallway.

You can also make a laminate threshold for the balcony block, which will be the same color as the main floor or contrast with it.

Types

The different models differ:

- material;

- size;

- color;

- fastening method, which can be open or closed.

- The open mounting option is easier to install, but its appearance is not as aesthetically pleasing due to the visible screw heads.

- Laminate thresholds with hidden fastenings look more beautiful. They hide all fasteners under the decorative strip.

Self-adhesive thresholds are also widely used.

Material

- Wood is considered the most aesthetically pleasing. Installation takes place using special mounting rails. Although wood is an ideal option for laminate flooring, it has certain disadvantages. For example, it has to be periodically sanded and re-varnished.

- Metal - the most durable threshold is made from it. It is popular among consumers due to its inexpensive cost.

Metal thresholds are made from:

- aluminum;

- of stainless steel;

- brass

Aluminum options are most often used. Their upper part is decorated with gold, silver or wood. In addition, they can be matched to flooring and door handles.

Aluminum sill

- Cork - the price of thresholds made from this material is similar to wooden products. They are quite flexible and can quickly apply the desired shape.

- Plastic - the cheapest products of this type are made from it, so there is no point in placing the main bet on them, since the quality corresponds to the price. Flexible thresholds for laminate flooring are also made from it, which are used to decorate pedestals and podiums.

- MDF profiles are also used for combining coatings. The product is classified as an inexpensive product and its main drawback is that it cannot resist the action of moisture.

Choice

Installing the threshold on the laminate is the final stage in the installation of floor coverings.

Therefore it is necessary to pay attention to:

- decorative function;

- practical purpose;

- color;

- surface texture;

- material;

- product strength;

- moisture resistance.

- It is also necessary to evaluate the functional purpose of the room. If the material comes into contact with ceramic tiles, for example in a kitchen or hallway, it must resist moisture. Therefore, moisture-resistant thresholds are used.

- Using thresholds, you can level out differences across planes. Agree that it is very difficult to guess in advance the difference in floor covering levels.

- When choosing the geometric dimensions of products, you should make a choice depending on the place where they will be used.

Using Thresholds

Today, flexible plastic molding, which is sold in rolls, is of interest. It is well suited for finishing curved floor surfaces.

Installation Features

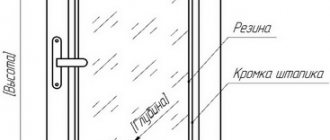

- The size of the threshold should be equal to the distance between the baseboards. To do this, prepare a tape measure, a pencil, a construction knife if you need to trim a plastic threshold, or a metal saw for metal, wooden or MDF thresholds.

- Before installation, heat the flexible threshold for laminate in hot water at a temperature of 60-70˚C.

- To fasten products in an open way, use self-tapping screws with a countersunk head. It is desirable that their color matches the threshold; if not, this gap can be filled with paint.

- If the difference between the laminated coating and ceramic tiles is less than 5 mm, the transition can be made with a wide threshold. You will get a natural connection of 2 different-level planes.

- The installation instructions will not cause any difficulties, so you can install it yourself.

Tip: install the expansion threshold between ceramic tiles and laminate, and install the straight threshold between laminate flooring.

When choosing a color, be guided by the color of one of the elements being connected or by a decorative element in the room. For example, chrome-plated products are suitable for painted door handles.

Installing a threshold in a doorway

Also make sure that the price category of the threshold and the floor covering coincide. You cannot supplement the elite coating with cheap plastic.

Tip: start selecting thresholds after you have chosen the flooring, its color, material and texture.

§ 4. APPLICATION OF THRESHOLDS

Many kitchens have dining and work areas that have different surfaces to emphasize their separation. Typically, ceramic tiles are laid in the work area, and laminate in the dining area. A special feature of this type of flooring is that it is necessary to leave a gap between different materials when laying them.

The main purpose of this gap is to compensate for the thermal expansion of tiles and laminates during fluctuations in temperature and humidity. In order to close this gap, a threshold is used between the laminate and the tile.

Types of balcony thresholds

Before you start creating and finishing the threshold for the balcony, you need to choose what it will be made of. The following types of design exist:

- Plastic. This is one of the most inexpensive options; such a threshold is not afraid of moisture, is resistant to mechanical stress, and is quite durable. The best option for installation is a PVC window sill, which can be installed ready-made: you just need to select the product to size or cut it.

- Cement-concrete. This is a more reliable and durable option, but its installation is more complicated, and it is advisable to finish the outside to give it a more aesthetic appearance. The covering can be made of tiles, laminate, linoleum, and other materials.

- Brick. It is quite difficult to lay out such a threshold; you need to calculate the dimensions and carefully level it. The finished structure can be finished with any materials, from wood to tiles.

- Wooden. The product is lightweight, easy to install, attractive in appearance, but it is resistant to moisture and pests. This balcony door threshold has a shorter service life than its analogues.

Related article: DIY balcony chest

§ 5. METHODS OF ATTACHING THRESHOLDS

Today, there are two ways to attach thresholds: external and hidden. External mounting is the most common. During the installation process, the threshold between the tile and the laminate is fixed using self-tapping screws and dowels. All thresholds intended for this method of fastening have symmetrical holes or marks for dowels. During installation, the base is marked through the holes. If the floor is concrete, you need to drill holes for the dowels, but if it is made of wood, then you can immediately screw in the screws without additional preparation.

Fastening thresholds with self-tapping screws

The hidden method involves using liquid nails or special glue to fix the threshold. This method is more labor-intensive, but due to the absence of visible fasteners, it is more aesthetically pleasing. As practice shows, thresholds for laminate and tiles are best secured externally.

If the gap between the coatings is arched, the threshold will have to be bent along an arc. To perform installation you need a special tool and certain professional skills.

How to Install Door Thresholds Without Drilling in the Floor

To zone a room, they mainly use door thresholds to complete the floor with different types of materials. To do this, you can use a functional design - a door threshold. This small part is mounted between rooms, in the hallway, bathroom, and also near the front door.

To achieve a harmonious combination of thresholds, the connections are equipped with frames to frame the boundaries. This is the final touch to the floor design. Allows you to visually divide a room into parts without compromising its unity.

But there is a problem. Over time, the products lose their shape, which leads to poor adherence to the floor. As a rule, manufacturers correct this error. Today, there are many types of thresholds in equipment that can be used without drilling. As an alternative, self-adhesive materials are used. As a result, the installation and operation process is simplified.

Please note: There are times when it cannot be secured to the floor using screws or hidden nails. This happens if a water or electric heated floor is installed. With such heating it is risky to drill a hole in the floor. It is necessary to purchase either self-adhesive thresholds or glue them using transparent silicone sealant.

To secure the thresholds in this way, two adhesive tapes are used, which are located along the edges of the inside of the product. In most cases, the tapes are made of rubber and have good adhesive properties. Designed for a one-time connection, but long lasting and reliable.

You can also use liquid nails for backup.

It's worth heeding a few tips to achieve the best success:

- The work surface must be thoroughly cleaned. Next, you need to degrease the surface, otherwise the connection between the floor and the threshold will not be strong enough;

- Liquid nails are applied as accurately as possible along the entire threshold, if necessary - in zigzags. To make it easier to squeeze the glue out of the tube, you should purchase a special gun;

- When the glue is applied, the threshold should be pressed to the floor, while trying to fit them together as firmly as possible. You need to press down on the threshold for a few minutes so that the glue can set. You can press it with something on top until it is completely dry. The result will be more reliable;

- During operation, the room temperature must be controlled. Ideally - from 0 to 30 degrees. At lower temperatures, the glue will take much longer to dry. When choosing a suitable threshold, you should consider not only the visual element, but also the reliability of the manufacturer.

Door thresholds can be installed in various ways. Every home craftsman can install door thresholds. Use these tips and tricks and do some home renovations yourself.

Decorative floor tiles

An indicator of good taste is to use the best experience of world architecture to decorate your monastery.

Outdoor tiles with stone imitation are in great demand (photo above). It creates a special harmony on garden paths in private homes, and on the external terraces of cafes and restaurants, such flooring material becomes an oasis for the eyes among the asphalt. For example, paving slabs called “Roman stone” are distinguished by a variety of colors and shapes, they are frost-resistant, non-slippery, durable and environmentally friendly, its photo can be seen on the right.

Types of docking thresholds

Thresholds come in several types. The choice must be made based on what materials are joined and whether they are located at the same level.

For example, a tiled floor may be slightly higher than a carpeted floor. This means that a threshold is needed that will create a smooth transition from one coating to another. Such thresholds that smooth out differences are called leveling .

If the floors are at the same level, a straight joining threshold . Such elements are called differently: T-moldings, straight sills, joint-overlapping profiles, etc. The main task they solve is decorating a straight joint.

If the joint is curved, it is necessary to use a flexible threshold . Before directly using such elastic profiles, it is recommended to heat them with a hair dryer - in this case they become more elastic. If a curved joint is made when combining floor coverings, it is advisable to achieve the same height, since flexible thresholds do not smooth out differences very well. When there is no drop, the flexible molding looks like a decorative border, and not as an obvious disguise of the joint.

Another type of threshold is the final one . It is used when you need to decorate not a joint, but the edge of a covering. For example, when finishing stairs, podiums, etc.

Materials

Various materials are used in the production of laminate flooring thresholds. Let's take a closer look at all the features and characteristics of structures of different manufacturers:

- Metal. As a rule, lightweight aluminum is used in production. Steel or brass is used a little less often. Such thresholds are the strongest, most durable and reliable. Thanks to these characteristics, they are very popular among modern consumers. Metal overlays are used in both home and commercial settings. One of the main advantages of thresholds made of aluminum or stainless steel is the variety of decor.

- Anodized. Thus, metal strips undergo anodic oxidation, after which a special metallized film appears on their surface. It can have different shades, from golden to bronze with patina. These options look very nice, but their main advantage is not only their attractive design, but also the fact that they are not subject to mechanical damage (chips and scratches), and are also protected from corrosion;

- Painted. Special polymer-powder mixtures of different shades are applied to the surface of such overlays. They can be either muted or bright and juicy. The result is very strong and durable coatings that are not afraid of abrasion or scratches. They can even be washed using aggressive chemicals;

- Laminated. Such aluminum strips are covered with a special durable PVC film, which has a texture that replicates laminate. Such options are the best-selling because they are inexpensive and come in a wide range;

- Chrome plated. Thresholds treated with chrome are incredibly popular due to their interesting and bright design, as well as wear resistance and durability. Over time, such glossy coatings do not lose their attractive appearance and do not require special care.

- Flexible . Plastic thresholds are simple and practical. They are presented in a wide variety of colors, since PVC itself is easily amenable to almost any processing. Many manufacturers produce such overlays for laminate flooring. A set of such parts consists of the following parts.

- Mounting rail (solid or perforated). It is attached to the base using self-tapping screws or mounting adhesive;

- Profiled threshold. This part is inserted into a special groove in the strip, after which it is securely fixed.

These types of thresholds are considered the most common and popular. There are also models made of wood or MDF on the market, which are universal due to their discreet and neutral appearance. However, they are expensive, and it is very difficult to find plastic or metal parts for them.

Soft rubber thresholds have good performance qualities. They have an excellent anti-slip effect. However, over time, such details may lose color saturation, and they usually look quite simple and unpresentable, but they are inexpensive.