The back wall of the cabinet - what is it made of?

Share on social media networks:

The topic of today's article is the back wall of the cabinet: what it is made of, different methods of fastening.

The purpose of the “backdrop” is to impart rigidity to cabinet furniture and hold the entire structure in a stable position. And rigidity is not the last characteristic for pieces of cabinet furniture. During use, the closet becomes filled with things. Due to uneven load distribution, an insufficiently rigid structure quickly deforms. It is the stiffening ribs inside the product and the back wall that make the furniture more stable. The most common types of materials for making “backdrops” are laminated chipboard or fiberboard. Now let's talk about how to attach the back wall of the cabinet. The sheet is mounted on the already assembled body in the “lying” position. Installation is carried out using nails or staples, overlapping. If installation is carried out on standing furniture, then the sheet is cut into pieces and mounted in fragments.

This option has only one advantage - low cost. There are many more disadvantages:

- The strength of a structure, especially a high one, is very relative.

- The surface of the fiberboard sheet is laminated or painted on only one side, so the material is susceptible to dampness.

- A small assortment of colors - about 5.

- Since the installation is overlapped, the material is visible from the end of the product.

- It is necessary to allocate a special place for installation. This is not easy in a small apartment.

- Often the material has a persistent unpleasant odor.

- Difficulties in attaching tall wardrobes to the wall.

Decor the back wall of cabinets and shelves with wallpaper

If you initially think that pasting the backs of furniture “in keeping with the theme” will only be the same as on the walls of the room - nothing like that! You should not limit yourself to such a trivial decision.

The decor of the back wall of the cabinet can be done with any wallpaper similar in color. If it's out of stock, look for it on sale shelves in stores and hypermarkets. You need less roll and you won't have to spend as much. Geometric patterns look especially impressive and win-win when pasting the back walls.

If you have a classic living room interior, you can choose wallpaper with luxurious patterns in the Provence or Baroque style to cover the open back walls of the furniture. This will add atmosphere and a touch of luxury to the overall style of the room.

Cheerful wallpaper will make the room more cute and cheerful. Especially if the room is on the shady side.

The use of bright, cheerful motifs is appropriate not only in cozy kitchens, but also in bedrooms and children’s rooms, wherever you want to enliven the interior and add a good mood to yourself and your loved ones.

What is the back wall of the furniture made of: chipboard

This is the preferred option, although the costs will be higher. The advantages of this option are the following:.

- Structural strength.

- Several mounting options - corners, euroscrews, eccentrics.

- If the fastening is “inset”, cabinet furniture has a neat appearance.

- Many color options. You can match the color of the back wall to the color of the body.

- Possibility of assembling the cabinet in a standing position. This means that there are conditions for working in confined spaces.

- Resistance to mechanical damage and high humidity.

Wardrobe assembly procedure

The first step is to install the base. Usually the stove is attached to stands that are located along the long side. It is mounted using Euro screws - fastenings with a recess in the head for a hex key.

It is important to know that a number of cabinet filling elements will also require preliminary marking and installation of fasteners, since this work will then be complicated.

The next step in the order of assembling the wardrobe is mounting the body. These are load-bearing parts.

Next, the back wall is attached. Shelves, hanging rods, that is, all the internal contents, are installed in the finished housing.

Assembling a sliding wardrobe with your own hands requires the master to have a clear understanding of the functions of all structural parts and fittings. Some shelves can be put back in place only after the furniture has been installed in a vertical position.

Lastly, the doors are mounted to the cabinet.

Advice. If the model has mirrors, it is attached to a fully assembled cabinet.

Before installing the side outer wall, we recommend pre-fixing the corner shelves that will be on the outside.

Video material

You found out what the back wall of the cabinet is made of. According to many people, the best option in terms of quality and price is laminated chipboard. Decide for yourself which option to choose based on your financial capabilities.

Source: serviceyard.net

The process of replacing nails with self-tapping screws

To connect the back wall of a cabinet with its body using self-tapping screws or nails, it is not necessary to work in the construction and furniture industry or contact furniture assembly specialists. It's very easy. Simply remove the nails from the wall and screw the screws into the holes from the nails. You can screw in the screws either by hand or with a screwdriver or screwdriver. The minimum set of tools for replacing nails with self-tapping screws yourself is:

- pliers;

- knife;

- Phillips screwdriver (or screwdriver).

If you prepare everything in advance, the process of replacing nails with screws will not take very long. It is as follows. First, we pry up the plywood with a knife, and then we pull out the nails with pliers. Both of these tasks are performed slowly, and care must be taken to ensure that the material is not damaged. Once the nails are removed and the plywood is removed, you can move on to the next stage - fastening with self-tapping screws.

Installation with self-tapping screws is carried out using the holes left by the nails. Typically, the boards from which furniture is made are soft and pliable. Self-tapping screws easily fit into them under just hand pressure, so you don’t even have to drill. To make this task easier, it is recommended to equip yourself with a screwdriver. In this case, it will be much easier and faster to screw in the screws.

Do you need a back wall in wardrobes?

Rigidity for large cabinets, such as sliding wardrobes, is an important characteristic. The internal content of an ordinary wardrobe is quite uneven; voluminous niches with rods alternate with narrow and dense shelves. The load inside the cabinet is distributed extremely unevenly. Both the shelves and the body require additional rigidity.

Another thing is built-in wardrobes and dressing rooms. Here, rigidity is given to the shelves in a different way - through additional consoles.

All other freestanding cabinets with sides, bottom and roof require a back wall, of course.

The consequences of deformation due to insufficient rigidity of the overall structure can be serious. Therefore, in addition to the rear wall, stiffening ribs made of the main material - chipboard - are laid between the wide spans of the internal sections at the project stage.

Cabinet wall decor

There is no need to decorate the backdrop in ready-made wardrobes, cabinets and chests of drawers - this element is decorated at the stage of furniture production (cutting, assembly). But if desired, the factory design can be changed using a mirror insert, which repeats the visible part of the backdrop in shape and size. This technique was used by Soviet furniture factories, but has not lost its relevance today.

A mirror located inside a china cabinet or cabinet, due to its reflective effect, will create the illusion of depth and help to more advantageously present the items on display. The reflective element can be attached to the backdrop with double-sided tape, liquid nails glue, special clips or thin strips nailed around the perimeter or along 2 opposite sides of the insert.

Other materials are also suitable for a cabinet with open shelves:

- Frosted glass.

- Glass with photo printing.

- Translucent plastic.

- MDF panels (painted, with patterns, textured embossing).

- Sheet panels for wall decoration (wooden, PVC).

- Wallpaper.

The original decor can be made from transparent epoxy resin with the addition of 1 or several color pigments. All these techniques can be used when decorating a free-standing or built-in wardrobe, assembled with your own hands. And additional lighting in open niches and above shelves will help emphasize the individuality and sophistication of the finished product.

What materials are used for the back walls?

The back wall of the wardrobe is most often 3-4-5 mm thick fiberboard, which is overlapped onto the ends of the chipboard.

The back wall is attached to the chipboard using small nails, but to increase the strength of the fastening, you can use self-tapping screws with a thickness of 3.5-4 by 16.

You can also find cases where the back wall is a laminated board 8 mm thick, hardboard and even OSB.

To decorate open niches, mirrors, various decorative panels with texture and embossing, painted glass, plastic are often used as back walls, complemented with built-in lighting.

Decorate the back wall using a contrasting color

Who decided that the backs of cabinets and shelving must necessarily match the color of the furniture or wallpaper? It's boring and dull. It is enough to choose a contrasting shade that is close to the design of the room and ordinary standard furniture will become designer!

Lifehack! Paint not only the back wall itself, but also some of the sides of the shelves. It looks interesting when not only the back, but also the end of the shelves is painted in a contrasting color to the body. This gives integrity to the overall design and decoration of the furniture.

You can decorate not only the back walls of a cabinet or rack, but also its entire “inside” - if you want drastic changes. It looks very stylish and unusual!

Fiberboard back wall fastening

There are two main ways to fasten fiberboard - overlapping and in a groove. The latter is typical for wall-mounted kitchen cabinets.

Let's now figure out how to properly attach the back wall in sliding wardrobes.

Difficulties arise at the assembly stage. The cast design of the assembled wardrobe is quite heavy and bulky. The most correct thing is to stuff the backdrop when the cabinet is “lying” face down. Then it is definitely not skewed and all diagonals are aligned.

However, this is not always possible.

- Firstly, to assemble a large cabinet lying down, you need a lot of free space. In ordinary small-sized apartments and narrow hallways there is simply no room for this.

- Secondly, if the cabinet is designed for the ceiling, then there is no point in assembling it lying down. Because of the diagonal, you simply cannot lift it later if the sides are laid solid from floor to ceiling.

- Thirdly, when lifting and moving, you can damage the front finish of the cabinet - after all, this is difficult to do even with a partner.

Do-it-yourself installation of a built-in wardrobe

Many home craftsmen can make a built-in wardrobe with their own hands. The main thing is where to start? What tool is needed? All technologies and solutions are quite simple, if you look at this issue in more detail. You must have a tool and the ability to use it, as well as a desire to make simple items for the home, in our case, making a built-in wardrobe with your own hands. The pressing question for Russians is the square meters of our living space, how to use them more rationally? One solution to this issue is a built-in wardrobe. Let's visually inspect your home, decide on the location, and think about the location of the shelves in the closet. We take a tape measure and begin to take measurements: the height of the walls from floor to ceiling, the distance between the walls. The distances of the walls do not always correspond to symmetry due to the peculiarities of national construction, and it is necessary to carefully determine the size. We draw up a design on paper schematically. You can tailor the project to standard components, namely: laminated chipboard furniture panels, sold in different sizes, and there are also different sizes of doors for ready-made wardrobes. We purchase self-tapping screws, angles, dowels, furniture panels, door guides and the doors themselves. The high-quality assembly of a sliding wardrobe depends on all components: the correct dimensions, good fittings and the skill of the performer.

Marking for shelves, installing corners.

Assembly begins with markings for the shelves. We draw along the level of the line, place a furniture corner under the bottom of the line - make a mark. Using a hammer drill, drill out the hole, insert dowels and screw the corners.

Fitting and installing shelves.

We lay and fasten the shelves to the corners. Perhaps the wall does not meet the ideal parameters, we make cuts in the shelves (from the wall side) to achieve proportions.

Vertical inner panel.

We install a vertical panel to the shelves inside the cabinet. We drill holes - in the panel and in the sides of the shelves for screeding using a confirming screw or self-tapping screw; you can also replace the connection with corners. For better fixation, the panel is attached to the wall or floor with corners.

Horizontal internal shelf.

We lay a horizontal shelf on top of our structure, level it, mark the edges and install the corners. Additionally, we connect it with a vertical panel.

Preparation and fastening of panels.

We prepare the panels for the front side of the cabinet. The width depends on the door guides, the length corresponds to the dimensions of the cabinet doors with a margin for free movement of the rollers.

Fastening the panel to the floor.

You can make a box for the lower element, thereby increasing the lift for the doors. The size of the box corresponds to the distance between the panels; we will fix it with the corners to the floor from the inside of the cabinet.

Fastening the bottom and top panels.

If the height of the assembled cabinet is below the ceiling, then the top panel is attached along the perimeter of the walls at the corners and overlaps the side panels. Or built in during furniture assembly, an additional element that closes the niche between the ceiling and the top panel of the cabinet

Installation of door guides.

We fasten the upper track along the edge of the cabinet, and move the lower track deeper for proper installation of the doors.

Doors for built-in wardrobes.

We insert the doors into the guides, snap the latches and adjust the mechanisms in the roller systems.

The back wall of the wardrobe, is it needed and what should it be made from?

In ordinary cabinets with hinged doors, as in other cabinet furniture, the back wall is always present. Sliding wardrobes with a more voluminous design are an exception. There is not always a back wall in them. Let's figure out why some wardrobes are made without back walls and whether they are needed at all.

What to make of and how to attach the back wall of the cabinet

Any cabinet, sideboard, china cabinet or cabinet is complete without a back wall. Backdrops, as furniture makers call them, can be made from different materials and mounted in different ways. But they all perform the same function - they maintain the correct geometry of the furniture.

Why do you need a back wall in cabinets?

Each closet has a number of shelves, drawers, hooks and hangers that serve as storage for clothes, shoes, accessories, books, dishes, small and large household items. All structural elements of the product experience different mechanical and physical loads. As a result, some shelves on which light things lie retain their shape, while others become deformed or warp under the weight of bulky household belongings.

In classic wardrobes without a back wall, hinged doors sag over time, and in coupe models, the doors move to one side or fall out of the sliding system guides. The backdrop gives the furniture structure additional rigidity and stability, preventing it from skewing and loosening.

A furniture box assembled in compliance with all technological processes will last for many years. The back wall covering the back of the cabinet will not only provide strength and hardness to the product. It will protect the interior of the wardrobe from ubiquitous dust, hide defects in the room walls from view, and give the product a finished look.

What is the best material to make the back wall of a cabinet from?

Furniture manufacturers most often use fiberboards with a thickness of 3, 4 or 5 mm to make backdrops. This decision is justified: fiberboard differs from other materials in its low price, it does not deform or crack under tensile and tearing loads, and does not occupy the internal space of a wardrobe or wall-mounted wall.

Depending on the design features and purpose of the furniture, backdrops are cut from different types of fiberboard:

- standard - the cheapest possible, having a natural grayish-brown tint;

- painted white, black and other colors;

- laminated;

- lined with a film that imitates the longitudinal section of wood (walnut, cherry, alder, etc.).

The second most popular material for backdrops is laminated particle boards. Compared to fiberboard, they are more durable, reliable and aesthetically pleasing. Laminated chipboards are resistant to scratches and high humidity. The large selection of colors available on the furniture market allows you to choose the desired texture, color and thickness.

Less popular materials for wardrobe backdrops include plywood, OSB boards, HDF, MDF panels (painted or covered with PVC film).

How to attach the back wall of a cabinet

The method of fixing the backdrop depends on several factors: the design of the product, its size, and the type of material used. In practice, furniture makers use 3 methods - overlapping fastening, in a groove and in the form of an internal insert.

Overlap fastening

The first method is the most common, due to its simplicity and accessibility. Anyone who knows how to use a screwdriver can master the technique of fixing an overlapping backdrop onto a frame. To do this you need:

- Take measurements from the back of the wardrobe without the back wall and transfer them to a sheet of fiberboard. Reduce the resulting parameters by 2 mm on each side. If this is not done, the “shaggy” edges of the fibreboard, protruding beyond the structure, will give the product an untidy appearance.

- Cut out the backdrop, place it on the box and secure it with screws (3x16, 3.5x16, 4x16). Start the fasteners from the corners of the body, and screw in the screws at a distance of 10-15 cm from each other.

Using a few tricks, you can make your work easier and improve the quality of the product:

- You should not use nails for fastening. They will not be able to be securely fixed in the chipboard and will fall out when transporting or moving the cabinet inside the apartment.

- If possible, it is better to use a solid backdrop. If the dimensions of the cabinet do not allow this, you need to cut out several fragments corresponding to the size of each section.

- It is more convenient to screw the backdrop if the cabinet is placed horizontally with its front side on the floor. This will avoid distortions and better fix the geometry of the product.

A large backdrop can be assembled from 2 separate pieces of fiberboard. To do this, you need to purchase a special plastic profile with 2 grooves from a furniture store and install it vertically in the center of the structure.

Groove mount

The second method of fixation is more often used when assembling kitchen sets. Due to the fact that the backdrop does not protrude beyond the frame, wall cabinets fit more tightly to the wall and are easier to adjust when hanging. The aesthetics of this option are often used by manufacturers of compact cabinets, buffets and sideboards.

Fastening into a groove requires great precision. Before closing the gap with the backdrop, you need to do some manipulations:

- Stepping back 10 mm inside the cabinet, cut a groove 5 mm deep around the perimeter of the bottom, roof and end racks of the wardrobe. The width of the groove must correspond to the thickness of the material used.

- Attach the backdrop at the stage of assembling the structure. First, screw the sides to the bottom, then insert the sheet into the grooves, cover with a lid and finally secure.

If the width of the groove is not sufficient for a sheet of plywood or fiberboard to fit into it without effort, the edges of the backdrop can be cut off a little with a sharp knife or ground off.

Function of the back wall in cabinet furniture

For a person who uses furniture at home, the back wall is assessed from the point of view of practicality. First of all, it covers all the cracks that arise due to the cabinet not being tightly connected to the wall:

- protects against dust, dirt (partly moisture) getting inside;

- serves as a barrier in the way of small objects - prevents them from falling off the inside of the shelves.

However, those who design, manufacture and design furniture know that the role of the back wall is much greater.

First of all, it enhances the rigidity of the entire structure. Thanks to it, the cabinet does not warp and “holds” its original geometric shape. Anyone who has assembled furniture knows how much easier it is to hang and adjust the fronts when the back is set diagonally and nailed to the body.

Also, the rear wall of the cabinet, as a connecting element in a plane perpendicular to the body, helps redistribute the load on the shelves. During operation, some shelves are loaded very heavily, while others are used to store something less heavy. Niches with clothes under hangers also provide a certain load. Unevenness leads to deformation, but due to a single back wall it is reduced.

How to fix a cabinet to the wall - a clever idea!

This article is based on a video. If you don't want to read, watch the video. Of course, everything didn’t fit into the video—the text describes the process in more detail.

The article is not a ready-made instruction. We are simply suggesting how to attach to a soft surface. Using our advice, you can solve your problem.

1000 people on the Internet are looking for how to fix a cabinet to a wall made of plasterboard, foam concrete, plastic panels. Because none of these materials can support the load. And on balconies this happens - there is no wall at all behind the plastic panels.

Now we will tell you how to secure a cabinet without drilling a single hole in the concrete.

The balcony is not at all simple; behind this wall there is a cardboard partition to the neighbor. There is absolutely nothing to attach to.

The master inspects the corners.

Marks the depth of the cabinet. Rearranges the laser level and makes marks on the walls. The shelves, ribs, and side walls will be placed according to the marks.

Next, the master takes the rail and screws it on. Wait, what is he doing? He didn't drill a single hole in the concrete.

After installing the first slats, the master attached the second ones to them. The joints of the slats overlap. This will add rigidity to the structure. All slats rest on the floor.

In the same way, the installer screws the strip to the ceiling panel.

One gets the feeling that the master doesn’t care at all what the cabinet’s surroundings are. If there had been drywall or foam blocks, he would have done the same.

Then it's time for shelves. There's an interesting point here. The professional rests the top rail against the floor and secures it to the vertical one. He screws the slats from the shelves to it.

He makes the response part in a similar way. First comes the horizontal rail. It rests on the vertical one, and it rests on the floor. The slats from the shelves are screwed to the vertical part.

The structure is then connected by installing shelves. The shelves provide such rigidity that even with excessive efforts it is impossible to move the frame.

But now the cabinet is not yet fully functional. It needs to be strengthened so that the weight can be placed on the shelves.

And here is that very secret moment. A professional screws on the vertical rail. He cut it out very tightly.

This is the secret. Throughout the cabinet, under each stick, the master secures a support. And each of its elements transfers its weight to the floor, and not along the walls. Moreover, our closet is built-in, not cabinet-mounted.

And this is what it looks like at the bottom. Again the supports were cut with high precision. We rested them on the floor again and screwed them back to the panels.

Here's a panoramic view. Supports stretch from the floor to each shelf. They are the ones who take the entire load that lies on the shelves.

If you like the cabinet itself, look at the instructions on our website. And then you can assemble one with your own hands.

Why are sliding wardrobes made without a back wall?

For built-in and partially built-in wardrobes, the back wall is not required. Such models often have internal filling in the form of a frame without side walls, and the shelves are additionally attached to the wall - therefore, from a design point of view, its role is minimal.

However, some customers of built-in furniture want to see the back wall in their closets. Usually this desire is explained by the fact that the wallpaper can be wiped off with clothes, and the backdrop is more practical and wear-resistant. But in order to install it, you have to make changes to the internal design of the wardrobe, add sections and racks, which leads to additional material costs and an overall increase in cost.

In voluminous non-built-in wardrobes (having side walls, a bottom and a roof) there is also sometimes no back wall. This is also due to considerations of economy and assembly features.

- To properly install the back wall, you need to assemble the cabinet lying down. In this position it is easier to catch the diagonals, align the body and fill the back. But in most cases, a large wardrobe is assembled “standing up” - too much space is needed to lift it and move it to the right place. Especially if the location is, for example, a narrow hallway.

- To make the wardrobe more rigid, with correctly installed rear sections, it is better to design it sectional. When each section is assembled separately and fits tightly with the rest, it is easier to assemble, move and attach the back walls. But this option will cost more, as was already written above.

Options for soundproofing a wall with a wardrobe

There are two ways to insulate an adjacent wall without repair. One option is to buy a wardrobe from a specialized company. If you purchase a ready-made design, pay attention to the following points:

- The back wall must be solid, without technological holes.

- All panel connections must be solid, without gaps.

- The cabinet should be tall and correspond in dimensions to the height of the room, right up to the ceiling.

- Choose a material such that it has minimal sound transmission capacity.

- The doors should have a large overlap with each other.

- It is advisable to install the finished cabinet close to the wall, so you will have to remove the baseboard from the floor.

Another option is to make a custom-made sliding wardrobe. In this case, some nuances should also be provided.

- Fasten the frame only to the floor and ceiling, and not to the walls.

- Remove all sockets from the back wall, and carefully seal the holes in which they were provided with foam.

- Make the back wall of the wardrobe from a thick sheet of chipboard, MDF or laminate.

- Consider the functional purpose of the internal shelves. The best insulators are tightly packed stacks of linen or clothing on wooden shelves, as well as continuous rows of books. Glass shelves with crystal glasses, as well as empty sections, on the contrary, can increase sound resonance from neighbors to the side.

What to make the back wall of a wardrobe from

The choice of material for the back wall of the wardrobe depends on the design and installation method.

The rear wall overlaps the body

If the backdrop is stuffed on the reverse side, overlapping the body, then it is better to use fiberboard with a thickness of 3-5 mm. This is a practical and inexpensive option. Less commonly, hardboard, plywood, OSB and other flexible sheet materials with a fibrous structure are used as back walls for sliding wardrobes of this type.

Step by step, installing the back wall on the wardrobe body will look like this:

- We align the assembled body of the wardrobe, “catch” the diagonals relative to the back wall. The backdrop cut to fit the section should be 2 mm smaller than the external dimensions of the niche on each side. For example, for a cabinet 2000x800 the backdrop is 1998x798, excluding the base.

- We screw the corners of the backdrop to the body. If you need to pre-mark, we mark. For fastening we use 3x16, 3.5x16 or 4x16 self-tapping screws. Small nails for installing fiberboard to chipboard are not recommended! Unreliable connection, popping out at the slightest attempt to move the cabinet.

- Next, we screw it onto self-tapping screws in the center of the sides, roof and bottom, then along the quarters, etc., until the distance between the fastening points is 10-15 cm. Here you can use small nails if the economy of self-tapping screws is so critical.

- We mark the fasteners along the internal stationary shelves and partitions in order to additionally “grab” the backdrop. It is not recommended to use the “eye” - there is a risk of making a hole in the fiberboard in the wrong place or damaging the shelf/partition by screwing in a self-tapping screw not in the center of the thickness of the chipboard. The distances between the shelves are measured, taking into account the thickness of the chipboard, 16 mm from the edge and 8 mm in the center are drawn along the fiberboard, and only then, along the line, starting from the center, screws are screwed in.

What is the back wall of the cabinet made of?

The back wall of the cabinet is made of fiberboard (Fiberboard), laminated chipboard (LDSP).

One sheet may not be enough to cover the entire back surface.

Some people suggest nailing the backs of cabinets.

Fiberboard consists of wood fibers, synthetic resins, fillers, and water.

- for general and special purposes;

- by hardness - superhard, hard, semi-hard, soft;

- by thickness.

Under load, the wardrobe may become deformed.

The use of a construction stapler is also not recommended.

The slabs can be smooth on one or both sides, varnished, covered with laminate film, or artificial veneer. They also differ in the degree of response to moisture, fire resistance, and exposure to sunlight. The most commonly used hard types are finely dispersed fraction (MDF) or hardboard and harder, modern HDF material made from coniferous wood.

To overcome the problems, you can design a compartment from sections, for each of which one sheet would be enough.

It is best to use self-tapping screws with a washer.

Chipboard is a mixture of sawdust and resins, which under the influence of high temperature and pressure turns into a homogeneous, durable material.

Fastening the back wall of the cabinet is not an idle question at all.

If laminated chipboard is used, then holes are first drilled so as not to split the board, and then self-tapping screws are screwed in.

- by grades, which are determined by the appearance of the product;

- by the number of layers;

- according to the degree of surface roughness: unpolished,

- by density;

- according to some other indicators.

quantity, colors not

different from color

put each other on

organically and unnoticeably

almost on the spot

The rear wall of the cabinet rigidly fastens the entire structure and holds it strictly in a vertical position.

Improves the rigidity of the entire structure and the fastening of sheets in the grooves selected using a milling cutter in the end posts, cover and bottom of the product.

As we can see from the table, what the back wall of the furniture is made of affects the appearance, ease of assembly, and strength. The back wall of the cabinet, the material of which is made of chipboard, is better in all respects, but also costs five times more. Naturally, its use significantly makes the product heavier.

It isolates the interior space of the cabinet and makes it aesthetically pleasing, especially if the wall behind it is uneven and unfinished.

You need to use multiple sheets.

In the case of tall models and heavy loads, for example, in the form of books, the question does not arise: what should the back wall of the cabinet be made of? For safety and reliability, this should be made from laminated chipboard.

Cabinets can be produced in the form of a separate case or built-in.

The sections are assembled separately, then they are connected to each other at the further location of the product and form a single structure.

In other models, the material from which the back wall of the cabinet is made can be fiberboard, which differs not only in thickness and density. Wood-fiber boards have a good margin of safety. You can also note the duration of operation (up to 30 years) while maintaining the original parameters, and the environmental safety of the slabs.

To prevent this, in addition to the rear wall, special stiffening ribs can be provided inside.

MDF, chipboard and fiberboard - what are the differences and what is better

MDF is a fine wood fraction from which furniture boards are made using hot pressing. The material is relatively new and environmentally friendly. It, unlike chipboard, does not use formaldehyde or other adhesive components. Often, these raw materials are purchased abroad, where safety standards are very strict. One of the positive aspects is the relative simplicity of processing the material, which allows products to have a more complex shape. The downside is the relatively high cost.

Materials and methods of furniture cladding

Regardless of which board you choose for your future furniture, its final cost will also depend on the material with which MDF or chipboard is lined. Today, the most popular are three options: veneering (veneering), lamination and caching.

Veneering , or in common parlance veneering, is the lining of a slab with a thin cut of natural wood. This method allows you to make the product as similar as possible to furniture made from solid wood. These products will, of course, cost more than laminated ones, but they will look very status and respectable. In addition, the vacuum pressing method allows you to literally wrap the veneer around complex carved parts, which means it gives even more naturalness. However, veneer requires careful treatment and special care, just like wooden products.

Lamination is the application of a composition of paper and polymers to a finished chipboard or MDF board, which, under the influence of high temperature, literally melt into the surface of the material, simultaneously acquiring the desired texture. This method of cladding is considered optimal in terms of price-quality ratio, because is not afraid of moisture, sun, temperature changes and retains its original appearance for many years.

Caching , unlike lamination, involves the use of glue. That is, a finished film with the desired texture is glued onto an array of MDF or chipboard. This method is the least expensive of those listed, but also not the most reliable. This cladding is much softer than laminate, which means it is not as resistant to mechanical damage and air humidity. If this option is quite acceptable for the bedroom, then for the kitchen it is better to choose a more reliable coating.

Disassemble and assemble

Let us immediately note that the method is not for the lazy. It is very long and quite complex, but very effective. If you do not have certain skills, it is better to immediately put the cabinet on the floor. After this, you should draw on a piece of paper all the centers of the shelves and various racks of the furniture being repaired. Next, you need to screw a part of the back wall along the entire length, clearly set the diagonal of the interior furniture and install it tightly by screwing the screws along the short part of the wall. The remaining parts of the back surface should also be screwed around the entire perimeter of the cabinet. Next, using the recorded dimensions, you need to draw lines and screw the back wall to the horizons and middle racks of the cabinet. If everything is done correctly, then the cabinet doors will open and close normally.

Self-tapping screw

Materials for processing furniture edges

The appearance of the finished furniture depends not only on the method of facing the slab, but also on the quality of the edge covering. Today, manufacturers use several materials for processing sections:

Melamine edging is a relic of the past, but is often used for economy-class furniture. It is a strip of decorative paper with hot-melt adhesive applied to one side. A special unit heats it and presses it tightly to the cut. If the paper is too thin, then all the flaws in the end, tubercles and pits, will be visible. The service life of such a coating is short, and melamine is not resistant to mechanical damage. If handled carelessly, it can crumble and crack, which will ruin the appearance of the product.

PVC (vinyl based) and ABS (acrylic based) edgebands are superior to melamine in both thickness and durability. These materials are more modern and therefore safer. In addition, they have a certain amount of flexibility, which allows them to stay on the cut for a long period of time. Such edges cost a little more than the first option, but their quality is much higher.

PVC profile is another method to cover the ends of the slabs. To do this, a special groove can be cut out in the cut (for a T-shaped profile) or it can simply be put on the edge (if the profile is U-shaped). This method does not ensure tightness, so it is absolutely not suitable for kitchen or bathroom furniture. But it is quite possible to decorate a work or computer desk by choosing a profile in a contrasting shade with the tabletop.

Rear wall in the cabinet: choosing material for fastening

Cabinets can be produced in the form of a separate case or built-in.

Built-in ones are mounted directly to the wall of the room at their location. The advantage of individual models is the ability to disassemble, move and place them in any place. Cabinet models always have a cabinet back wall. It isolates the interior space of the cabinet and makes it aesthetically pleasing, especially if the wall behind it is uneven and unfinished. The rear wall of the cabinet rigidly fastens the entire structure and holds it strictly in a vertical position.

The back wall of the cabinet is made of fibreboard (fibreboard).

For safety and reliability, it should be made from chipboard.

The wardrobe is divided into sections, drawers, shelves and is filled with things very unevenly. Under load, the wardrobe may become deformed. To prevent this, in addition to the rear wall, special stiffening ribs can be provided inside.

In addition to the rear wall, special stiffening ribs can be provided inside.

Wood-fiber boards have a good margin of safety.

What is the back wall of the cabinet made of?

The back wall of the cabinet is made of fiberboard (Fiberboard), laminated chipboard (LDSP).

One sheet may not be enough to cover the entire back surface.

Some people suggest nailing the backs of cabinets.

Fiberboard consists of wood fibers, synthetic resins, fillers, and water.

Varies:

- for general and special purposes;

- by hardness - superhard, hard, semi-hard, soft;

- by thickness.

Under load, the wardrobe may become deformed.

The use of a construction stapler is also not recommended.

The slabs can be smooth on one or both sides, varnished, covered with laminate film, or artificial veneer. They also differ in the degree of response to moisture, fire resistance, and exposure to sunlight. The most commonly used hard types are finely dispersed fraction (MDF) or hardboard and harder, modern HDF material made from coniferous wood.

To overcome the problems, you can design a compartment from sections, for each of which one sheet would be enough.

It is best to use self-tapping screws with a washer.

Chipboard is a mixture of sawdust and resins, which under the influence of high temperature and pressure turns into a homogeneous, durable material.

Fastening the back wall of the cabinet is not an idle question at all.

If laminated chipboard is used, then holes are first drilled so as not to split the board, and then self-tapping screws are screwed in.

Varies:

- by grades, which are determined by the appearance of the product;

- by the number of layers;

- according to the degree of surface roughness: unpolished,

polished, laminated;

- by density;

- according to some other indicators.

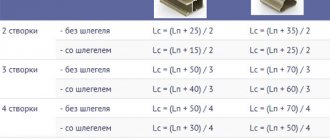

| Properties | Fiberboard | laminated chipboard |

| Price | Low | High |

| Thickness | 3-5 mm | 10,16,18 mm |

| Influence on the strength of the structure | Not recommended for tall models | Significantly enhances strength |

| Reaction to moisture, scratches | One side with non-laminated surface may absorb moisture, deep scratches may damage the sheet | Laminated surfaces do not allow moisture to pass through, and scratches do not cause significant damage to the material. |

| Variety of colors | Five colors | Unlimited quantity, colors do not differ from the color of the product body |

| Possibility of wall mounting of tall cabinets | Complicated due to the small thickness of the plate | Any fastening to the wall |

| Parts Compatibility | You can only overlap each other, which can be viewed | Inlay into each other, organically and imperceptibly from the outside |

| Assembly | Assembly is done in a lying position, which requires additional space | The cabinet is assembled in the “standing” position, almost at the installation site |

The rear wall of the cabinet rigidly fastens the entire structure and holds it strictly in a vertical position.

Improves the rigidity of the entire structure and the fastening of sheets in the grooves selected using a milling cutter in the end posts, cover and bottom of the product.

As we can see from the table, what the back wall of the furniture is made of affects the appearance, ease of assembly, and strength. The back wall of the cabinet, the material of which is made of chipboard, is better in all respects, but also costs five times more. Naturally, its use significantly makes the product heavier.

It isolates the interior space of the cabinet and makes it aesthetically pleasing, especially if the wall behind it is uneven and unfinished.

You need to use multiple sheets.

In the case of tall models and heavy loads, for example, in the form of books, the question does not arise: what should the back wall of the cabinet be made of? For safety and reliability, this should be made from laminated chipboard.

Cabinets can be produced in the form of a separate case or built-in.

The sections are assembled separately, then they are connected to each other at the further location of the product and form a single structure.

In other models, the material from which the back wall of the cabinet is made can be fiberboard, which differs not only in thickness and density. Wood-fiber boards have a good margin of safety. You can also note the duration of operation (up to 30 years) while maintaining the original parameters, and the environmental safety of the slabs.

To prevent this, in addition to the rear wall, special stiffening ribs can be provided inside.

How to strengthen the back wall of a cabinet?

Fastening the back wall of the cabinet is not an idle question at all. Some people suggest nailing the backs of cabinets.

The advantage of individual models is the ability to disassemble, move and place them in any place.

Yes, this method allows you to do it quickly, but such fastening of the rear walls of the cabinets reduces the rigidity of the structure and its strength. In this case, the material of the body and walls is destroyed, creating difficulties in the future when disassembling such a product. The use of a construction stapler is also not recommended. It is best to use self-tapping screws with a washer.

The back wall of the cabinet, the material of which is made of chipboard, is better in all respects, but also costs five times more.

If laminated chipboard is used, then holes are first drilled so as not to split the board, and then self-tapping screws are screwed in. Improves the rigidity of the entire structure and the fastening of sheets in the grooves selected using a milling cutter in the end posts, cover and bottom of the product. In this case, it is important that the dimensions of the sheet to be fixed coincide very precisely with the dimensions of the area to be closed.

Particleboard is a mixture of sawdust and resins.

Fastening is carried out around the perimeter:

- to partitions and end walls;

- to the ceiling from above;

- to the base of the structure;

- to permanently fixed shelves.

They also differ in the degree of response to moisture, fire resistance, and exposure to sunlight.

How to fasten the wall at the joints?

One sheet may not be enough to cover the entire back surface. To do this you need to use several sheets. In this case, the following options for connecting sheets are possible:

- if the joint lies at the end of the partition:

– both sheets are pressed against the partition using self-tapping screws with a washer;

– the sheets are overlapped;

- if the joint does not fit on the end of the partition:

– both sheets are connected using a mortise strip into which they are inserted;

- the sheets are glued together.

The slabs can be smooth on one or both sides, varnished, covered with laminate film, or artificial veneer.

To overcome these problems, it is possible to design the compartment from sections, each of which would require one sheet. The sections are assembled separately, then they are connected to each other at the further location of the product and form a single structure.

Fiberboard consists of wood fibers, synthetic resins, fillers, and water.

50 photo ideas: the back wall of the cabinet

We recommend articles on the topic

Furniture stapler. What is it and how does it work?

There are a wide variety of different types of tools you need to make your life easier. Stapler is one of them. It has been popular for many years. There are many modern types...

What is artificial suede and what are its features?

Artificial suede (or, as it is also called, Alcantara) is a textile material that imitates natural suede fabric and is an interweaving of natural and synthetic threads. Thanks to…

Getting rid of the smell of urine on the sofa

It is so important to keep your home clean and tidy, but often unpleasant odors can ruin everything. Perhaps the most favorite place for the whole family is the sofa, and it is the one that is subjected to the most…

Fastenings for shelves in the closet. What are they and why are they needed?

Part of each cabinet is shelves, thanks to which compact storage of various items is organized. A long and high-quality service life directly depends on the reliability and correctness of fastening...

We make decoupage of the kitchen table with our own hands

“Hand made” things in the interior are valued more and more. They give the house individuality and special zest. Every housewife dreams of creating a cozy atmosphere in her apartment at minimal cost,…

Types of forged hallway hangers with design options

The hallway is the first thing a person sees when entering a house. When designing it, we often encounter a lack of free space. It’s not always possible to fit a closet or separate shelves for…

Source: https://berkem.ru/drugoe/esli-stenka-zadnyaya-ne-znachit-nevazhnaya/

How to choose quality fittings

There are a great variety of alloys from which furniture fittings are made, so there is no need for a non-specialist to understand all these intricacies. In addition, manufacturing companies are constantly improving the quality of their products and patenting new compositions. The main things you should pay attention to when choosing accessories:

- The manufacturer's logo must be in the most visible place and clearly legible.

- The color of the metal must be uniform, without stains, burrs, roughness, or streaks.

- Open fittings are a thing of the past; it is better to give preference to hidden mechanisms.

- When opening and closing doors, they should not creak, knock, wobble or generally cause any suspicion.

- Drawers should not rattle, jam, or slide to the side.

- The finishing mechanism, if present, must work without any complaints.

By following these recommendations, you can not only choose high-quality furniture that is suitable in price and functionality, but also purchase a product that will last for many years, maintaining its presentation.

Source: pitmebel.ru